Wood lathes are the most common machine tools used in the popular woodworking, with high efficiency, high precision and long service life. Although the technology content of wood lathes is getting higher nowadays, in the use of wood lathes, it is inevitable that various issues will be encountered. Some problems can be solved by simple inspection and operation by users, and it is not necessary to contact maintenance workers. Then let STYLECNC summarize the various problems and solutions that may occur in the operation of wood lathes, especially for the CNC wood lathes.

Case #1. After power on, there is no indication of power supply and no information on the display.

Problem:

The power cord is not connected properly or the fuse is burnt out. The signal cable is loose or detached.

Solution:

Check the wiring of the power cord, disassemble the electric box and replace the fuse, and check whether the power cord and the signal cord are in good contact.

Case #2. The display is normal but one click button is invalid.

Problem:

The click button is damaged, the tail wire of the click button is off or short-circuited.

Solution:

Replace the click button and reconnect the tail wire.

Case #3. The wood lathe can be turned on normally, but the power motor cannot run.

Problem:

The power supply is out of phase, the fuse is burnt out, or the thermal relay has tripped.

Solution:

Check the power wiring, replace the fuse, and reset the thermal relay.

Case #4. When the wood lathe is working, the movement in a certain direction suddenly stops with vibration of the stepper motor.

Problem:

There is debris in the moving direction of the stepper motor, which leads to blocked rotation, the column is too large, the inner diameter of the center sleeve is small, and the resistance is large, and the driver is faulty.

Solution:

Remove debris, restart the power supply, unify the size of the column and the center sleeve, and replace the driver.

Case #5. The woodturning tool stops at one place while working, and the stepper motor has no vibration.

Problem:

The stepper motor control wire is broken.

Solution:

Reconnect the control line. In particular, check whether the plug of the control system wiring board under the button control board is loose or falling off. Whether the wiring and plug on the stepping motor are loose or fall off.

Case #6. The surface of the finished product shows regular screw patterns.

Problem:

The center sleeve is not processed according to the requirements. The concentricity is not high. The standard processing method is to turn the bearing table and the inner circle into one tool. The processed parts must not be moved in the middle, otherwise the inner and outer circles will not be concentric.

Solution:

Click to re-customize the center cover.

Case #7. Some stepper motors rotate in only one direction (the tool travels in only one direction).

No.1 Problem:

Is there any voltage change between 5V and 0V when measuring the 5V interface and DIR of the wiring board when clicking forward and backward? If not, it belongs to data line or control system failure.

Solution:

Replace the data cable or repair the CNC control system.

No.2 Problem:

There is a problem with the wiring board of the motion CNC control system. The judgment of this problem can exchange the plug of the driver to the wiring board. If it is normal, it is a wiring board problem.

Solution:

Replace the wiring board.

No.3 Problem:

The drive is faulty, you can exchange the motor plug on the same drive, if the fault is transferred to another axis, it can be determined that the drive is faulty.

Solution:

Replace the drive.

Case #8. Large vibration.

Problem:

The loading center point is wrong. Turn the thimble, the center of the center sleeve, and the tailstock thimble to be out of focus.

Solution:

Adjust the orientation of the feeding rack.

Case #9. The thickness and length of the finished product change regularly.

Problem:

Drive failure.

Solution:

Replace the driver. To check the drive failure method, you can click the "Reset Zero" button again, and make a precise mark on each axis after the standby stops. Then the cycle will be processed multiple times, each time checking the position of the mark misalignment, if there is a regular change, it can be judged to be a driving fault.

Case #10. During the processing, the machine is stuck and the motor is abnormally ringing.

Problem:

The workpiece is too large.

Solution:

Replace the center sleeve. It is normal for the diameter of the center sleeve to be less than 2mm smaller than the diagonal of the column, and greater than 2mm. The motor will be unable to move due to the drop.

Case #11. The stepping motor beats repeatedly and does not operate normally.

No.1 Problem:

The outer film of the shielded wire is peeled off or the grounding is poor.

Solution:

Check the shield terminal and ground terminal.

No.2 Problem:

The setting speed is too high

Solution:

Adjust the manual high and low speed again, and adjust the manual high and low speed according to the manual.

Case #12. The woodturning project is not smooth.

Problem:

The turning tool was not sharpened.

Solution:

Grind the turning edges on both sides of the V-shaped turning tool symmetrically. Grind the tip of the tool on the grinding wheel to a plane of 0.6mm. Then grind the corners of the two ends on the whetstone to make the tip of the match U-shaped.

Case #13. The wood lathe project has stepped ripples.

No.1 Problem:

The slider or ball screw is poorly lubricated. You can turn the screw by hand when the lathe is powered off. If the resistance is large or the resistance is uneven, it can be judged to be a problem of the guide rail slider or the ball nut.

Solution:

Inject diesel cleaning slider and ball nut into the oil injection hole, and then inject oil for lubrication.

No.2 Problem:

There is a gap between the coupling and the stepper motor. It can be checked by shaking the tool holder back and forth in the direction of the slideway when the lathe is powered on. Because the stepper motor has a self-locking function, the tool holder cannot be pushed under normal circumstances.

Solution:

Tighten the gap between the screw and the stepper motor.

Case #14. During program execution, it returns to the monitoring state and the work stops.

Generally, it is caused by malfunction of the monitoring program or strong magnetic interference. The strong magnetic interference can be solved by grounding or shielding. If you do not follow the program or start the program without following the execution instruction, you will immediately return to the monitoring state. Generally, the monitoring program or computer hardware fails, and you can replace the suspicious chip, such as the off-chip program memory chip, programmable interface chip, or the microcontroller itself. Sometimes the failure of the off-chip data memory can also cause this phenomenon. Otherwise, you have to find the manufacturer to re-debug.

Case #15. The CNC machining program is often lost.

If the CNC machining program is lost after the control system is powered off, and the CNC machining program is re-entered after the wood lathe is powered on, the lathe can be processed normally, it may be that the backup battery voltage is reduced or disconnected, resulting in the machining program in the data memory after the lathe is powered off Unable to keep and lose. Replace the spare battery. If the processing program is often lost partly or completely during the processing, it is most likely that the data memory is faulty. At this time, the off-chip data memory or the single chip microcomputer itself can be replaced.

Case #16. The wood turning tool does not return to zero after the end of the program.

Usually it is the control system failure. When the tool is feeding or processing, the stepping motor runs at a low speed, and when the program returns to zero, it needs to be quickly retracted. The stepper motor runs at high speed and uses a high-voltage drive power to increase the output torque. There is a switch transistor that controls the output of the high-voltage drive power supply. When the switch transistor is damaged, the high-voltage power supply cannot be turned on when the high-speed return to zero, and the output torque of the stepper motor is not enough, so that the tool does not return to zero. It can be eliminated by replacing the switch transistor.

Case #17. The wood lathe tool is out of position when it returns to zero.

It is usually caused by too much resistance of the mechanical transmission system. During cutting feed, the tool holder runs at low speed, low voltage drive, and the stepping motor has a small running torque, which is not enough to overcome the resistance and cause lost steps. When returning to zero, the stepper motor is driven by high voltage, which has high running speed, large torque, and no cutting resistance. The stepper motor does not lose steps. In this way, losing steps when going and returning normally will cause non-return to zero phenomenon. At this time, you can check whether there is iron debris on the transmission gear in the stepping motor reduction box or the transmission gear between the stepping motor and the lead screw, or whether the sliding plate insert is too tight to increase the running resistance.

Case #18. The size error of the workpiece after processing is very large.

One possibility is that the lead screw or lead nut is loosely connected to the lathe. There is no resistance to the knife during idling, and the sliding plate operates normally. Due to the increase in cutting resistance during processing, the connection between the lead screw or the thread mother and the lathe is loose, causing the size of the processed workpiece to drift. Tighten the connection part, the fault can be eliminated. Another possibility is caused by the electric tool holder. If the tool post cannot be locked automatically after the tool is changed, the tool will deviate from the processing point during cutting, which will also cause the above phenomenon. At this time, the tool holder locking device and the tool holder control box should be checked.

Case #19. The local size error of the workpiece is large.

The main reason is that the gap between the mother wire and the lead screw is too large. Because the wire mother and the screw run in a certain section for a long time, the gap in this section increases. At the beginning of the program, the measured screw clearance is compensated into the program, but it cannot be compensated in the wear section, so that the local dimensions of the workpiece are out of tolerance. The solution is to repair or replace the screw.

Case #20. The electric tool holder cannot be positioned and rotates more than once when changing tools.

This is because when the program requires a certain number of tools, the electric tool holder is selecting the tool. When it rotates to this number of tools, there is no response signal, which makes the tool holder rotate more than can not be positioned. The Hall element on the electric tool holder should be checked. When the Hall element is damaged, no signal output is detected when the desired tool is in place, which causes the above phenomenon. Replace the Hall element of this cutter.

Case #21. After the program runs, the stepper motor will not shake.

This phenomenon is generally caused by the phase failure of the stepper motor or its control system. It is possible that the stepper motor itself is faulty or its drive circuit is faulty. First check whether the connection plug of the stepper motor is in good contact. If the contact is good, the motor without failure can be replaced to verify whether the motor is good. If the motor still does not work normally after replacing the motor, it means that the control part is not normal. You can focus on checking the high-power transistor on the driver board and the protection element release diode.

Case #22. The table suddenly stopped while the CNC program was running.

This phenomenon is generally caused by mechanical failure, but it may also be caused by a failure of the CNC control system. At this time, the worktable can be returned to the original point, and the processing program can be restarted. If the worktable always stops when it reaches a certain position, it should be a part of the transmission system that is damaged, deformed, or stuck by a foreign object. First cut off the power, and then check whether the gap between the screw nut and the screw or the sliding plate insert is too tight, whether there are foreign objects in the ball guide groove of the ball screw, whether the screw is bent or deformed, and whether the flexible gear in the stepper motor reducer is loose or foreign objects stuck. If there is no abnormality in the manual cranking, the CNC control system is faulty and should be checked according to case #14.

Case #23. Stepper motor loses steps at high speed.

It may be that the driving power supply voltage is reduced, so that the output torque of the stepper motor is reduced. Focus on the drive power supply section. When the high-voltage switch transistor is damaged, the high-voltage power supply is switched on. At high speeds, the output torque of the stepper motor decreases and steps are lost. There may also be a mechanical failure somewhere, so you should also check the screw, wire mother, sliding plate, stepper motor reducer and so on. When components are bent, deformed, or have foreign objects, the running resistance will increase. The phenomenon is not obvious when running at low speed, but the running resistance cannot be completely overcome at high speed.

FAQs

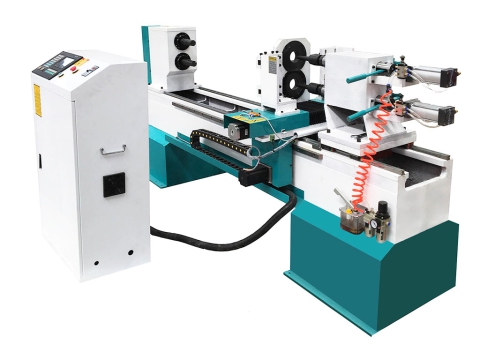

What is a Wood Lathe?

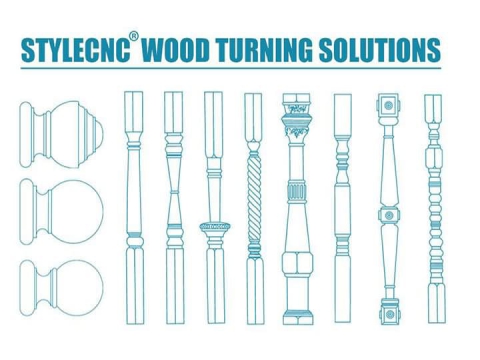

Wood lathe is a woodturning machine tool that rotates the workpiece on its axis to perform various operations, including turning, cutting, sanding, broaching, carving, knurling, drilling, deformation or facing with cutters that are applied to the workpiece to create an object with symmetry about an axis of rotation. Wood lathe is a type of wood turning machine for popular woodworking. There are two types of power wood lathe machine: fully automatic CNC wood lathe and semi-automatic wood lathe. Automatic wood lathe is refer to a kind of woodworking power tool with computer numerical controlled, all the work is automatic from the beginning to the end. Semi-automatic lathe machine is as same as fully automatic lathe machine but the feed work is finished by manually or by CNC machinist.

How to Use a Wood Lathe Safely?

The use of woodworking lathes is getting wider, including solid wood staircase columns, solid wood furniture accessories, tables and chairs legs, wooden crafts, etc. Many products of woodworking machinery will have their own user rules. For a woodturner, woodworker, operator, or beginner, what should be paid attention to before using a CNC woodworking lathe?

Safety Rules.

1. The device should not be used in a humid environment. The ambient temperature is 5 ℃ ~ 50 ℃, and the stepping motor ≤100 ℃ is normal.

2. The equipment voltage should be stable at 380V, with a fluctuation of ± 2.5%. The wire is three-phase four-wire with a wire diameter greater than 2 square millimeters. The wiring should be fastened, otherwise it will easily burn the machine parts. There should be no high-frequency (such as plasma) and high-voltage equipment near the line. High-frequency interference can easily cause the machine to malfunction and damage the equipment. The machine must be reliably grounded with a ground wire.

3. The air source pressure is 0.4-0.8MPA, and the air pressure can be adjusted appropriately according to the wood, so that it can be rotated and does not fall off after being inserted into the wood. Insufficient air pressure and sudden air cut will be very dangerous, and Yi Mufang will fly out and hurt people.

4. Check the parts before processing, the tailstock should be locked, the guide rails should be cleaned to prevent foreign objects from jamming, and sheet metal hand and other objects should not be placed on the head box. The correct installation direction and length of the tool.

5. Do not touch the machine parts and processed parts in operation with your hands, and do not put your hands on the moving parts that are prone to bumps. When adjusting the machine or cleaning the wood chips, you must stop the machine.

6. The operator must operate in accordance with the operating regulations. The machine must not be left during operation. The processing of new products needs to be slow to fast. The experimental processing of the purpose may cause damage to the machine and personnel accidents.

Issues that should be paid attention to before start working.

1. Do not install the device during lightning or thunder, do not install the power socket in a humid place, and do not touch the uninsulated power cord.

2. The operator on the machine must go through rigorous training and must pay attention to personal safety and machine safety during the operation process, and operate the computerized woodworking lathe in accordance with the most operating procedures.

3. The power supply voltage requires 220V/380V, the fluctuation is less than 5%. If the power supply voltage is unstable or there are high-power electrical equipment around, please choose a regulated power supply under the guidance of professional and technical personnel.

4. For CNC woodworking lathes, the control cabinet must be grounded, and the data cable cannot be plugged in while it is live.

5. The operator must not wear gloves to work, it is best to wear protective glasses.

6. The body of the machine is a casting, which is relatively brittle. It is necessary to use appropriate force when installing the screw to prevent slipping.

7. The tool must be installed and clamped to keep the tool sharp. The blunt tool will reduce the turning quality and overload the motor.

8. Do not put your fingers into the working range of the tool, and do not remove the turning head for other purposes. Do not process materials containing asbestos.

9. Do not exceed the machining range, cut off the power when not working for a long time. When the machine moves, it must be carried out under the guidance of professionals.

10. If the machine is abnormal, please refer to the operation manual for troubleshooting methods or contact the dealer to solve it, so as not to cause human damage.

How to Maintain a CNC Wood Lathe Machine?

CNC wood lathe machine is the most important processing equipment in the wood processing industry. Its high processing efficiency, high precision, cost saving and other characteristics have brought good economic benefits to the enterprise. However, it is necessary to do a good job of maintenance and maintenance during use to ensure that the lathe can successfully complete processing operations and extend the service life.

1. The new lathe should be inspected once every 10 days to avoid loosening of the screws during the running-in process. Tighten them in time if they become loose, and check them regularly afterwards.

2. Wood flour should be cleaned once every 2 hours of work.

3. Every 10-15 days of work, the spindle bearing should be filled with oil. Especially the sliding guide should pay special attention to refueling on schedule.

4. Every 10-15 days of work should be replenished with the tool post bearing.

5. Check the lubrication of the ball screw end bearing every 30 days.

6. After the new V-belt has been working for three months, it should be checked for wear. When the V-belt is too loose, use the motor fixing plate to adjust the tightness of the V-belt.

7. The dust cover plays the role of both dust prevention and safety, and must not be removed casually.