What Is A Wood Lathe Machine?

Woodworking has become fun and easy using modern machines. Nowadays, different models of woodworking machines are available on the market. These tools have made the job more controlling and offer better precision with fine finishing.

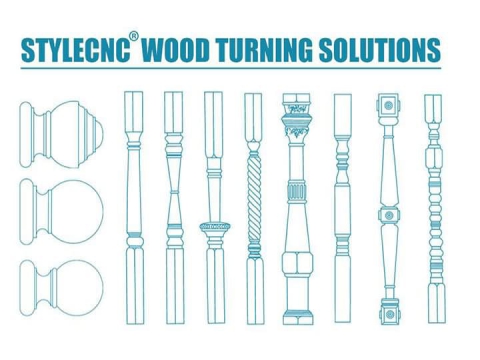

A wood lathe is a power tool that fixes a workpiece on a rotating spindle and is usually used for machining cylindrical workpieces. General wood lathes are equipped with various special tools, which can complete inner and outer circle processing, drilling, threading, cutting groove, end surface processing, outer circle, drilling center hole, turning hole, reaming hole, turning cone, turning forming surface, knurling, coiled spring and other processing procedures.

Wood lathe machines are used for shaping wood. They are also used for crafting symmetrical objects, spindles, and furniture components. These machines are popular among professionals and hobbyists as well.

How Does A Wood Lathe Machine Work?

A wood lathe machine works combining rotation, cutting tools, and skilled craftsmanship together to shape wooden objects into beautiful designs.

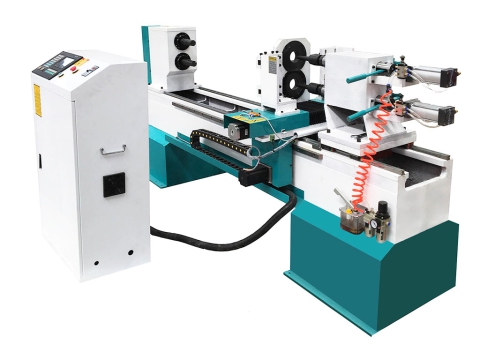

The lathe is driven by an electric motor, and the spindle is rotated through a belt and gear transmission system to drive the workpiece on the spindle chuck to rotate. Then, the lathe is fixed on the tool holder for turning. The main workpiece is a round rod. The work includes turning the end face, inner and outer diameter, arc, taper, drilling, boring, eccentricity, embossing, cutting, grooving, and threading.

So, the basic working process is determined in 3 steps. They are,

✔ The rotational movement of the wood piece at a controlled speed

✔ Fixing the cutting tools ( gouges, scrappers, parting tools) properly

✔ Removal of the material and shaping the workpiece into a smooth finishing object

Due to the development of the industry, the actual work requirements are increasing day by day. To adapt to the trend of various processed products and modern automated processing to meet the needs of production, a variety of different functions and characteristics are developed:

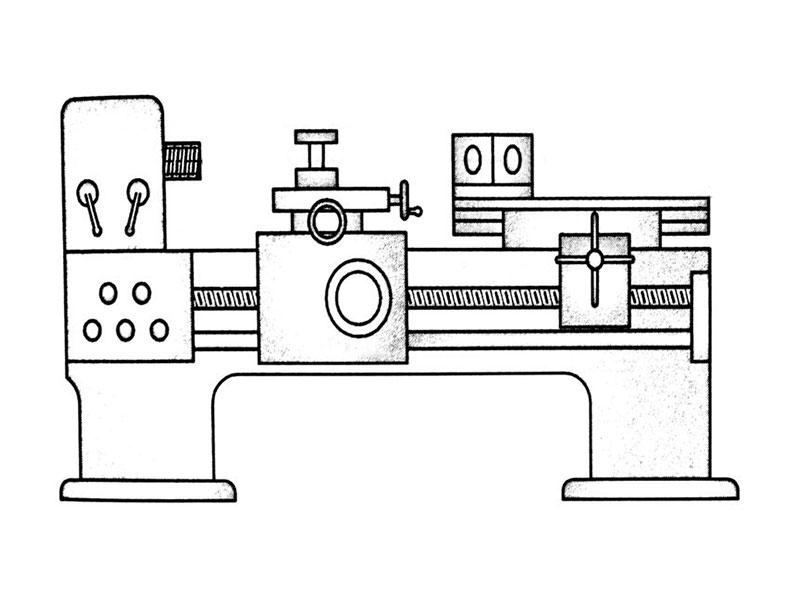

Centre Wood Lathe.

Centre lathes are the most widely used type of lathes. In the early days, the transmission of ordinary lathes was driven by a belt-transmitted tower wheel. Today, gear transmissions have been used. The advantage of the gear transmission is that it can accurately grasp the speed of the main shaft, and there is no situation where the speed of the main shaft is too high, the friction of the belt is consumed and slips. Because the main shaft is placed horizontally, it is also called a horizontal lathe. If the bed surface is notched, it is a notched lathe machine.

Bench Wood Lathe.

Bench lathe machines are also called tabletop lathe machines. Their type and structure are similar to centerwood lathes. They are usually installed on work tables and named after them. They are suitable for the production of precision measuring tools, instruments, and small parts.

Vertical Wood Lathe.

The main axis of the vertical lathe is installed vertically, the bed is horizontal, and the workpiece is placed on the rotatable bed. Especially suitable for processing workpieces with large diameters but short lengths.

Turret Wood Lathe.

A Hexagon lathe, also known as a turret lathe, is designed to replace the tailstock of an ordinary lathe with a hexagonal rotating turret. Especially suitable for processing a large number of workpieces in various processing procedures (such as drilling, reaming, and boring), suitable for mass production.

Automatic Wood Lathe.

The automatic lathe can automatically turn according to the processing order of the work. After turning, it will automatically retract the tool, feed it, and turn the next finished product. It is suitable for the mass production of small-diameter workpieces.

Copying Wood Lathe.

Copying lathes, also known as imitation turning lathes, use the stylus to move according to the shape of the model or template, and the turning tool also moves the turning work, so the same workpiece as the model can be turned correctly.

CNC Wood Lathe.

The full name is "computer numerically controlled wood lathe", referred to as "CNC machine tool". The advantage is that it is suitable for processing large quantities of workpieces with complex designs and high precision requirements.

Benefits and Demerits

| Pros | Cons |

|---|---|

| Capable of creating a wide range of objects from small decorative items to large furniture pieces. | High-quality lathes can be expensive |

| Allows for detailed and symmetrical shaping of wood. | Requires significant space |

| Enables artisans to experiment with different shapes and designs. | Operating a lathe effectively requires practice and skill |

| Speeds up the process of shaping wood compared to manual methods. | |

| Offers a platform for developing advanced woodworking skills. |

Buying Considerations!

Buying a wood lathe machine is a profitable investment. These machines have changed the course of wood crafting. Woodwork is now faster and easier with wood lathe machines. Yet, before buying a machine it is wise to follow a few considerations. It will increase the chance of growing the business or fulfilling your projects within affordability.

Before purchasing your CNC wood lathe machine,

1. Determine the purpose and your project size

2. Consider the power and speed of the machine. A machine with a variable speed is more capable

3. Consider the lathe’s capacity, including the distance between centers and swing-over bed

4. Look for a sturdy, well-built lathe made from durable material

5. Check for additional features like tool rests, faceplates, and chucks

6. Set a budget that balances your needs