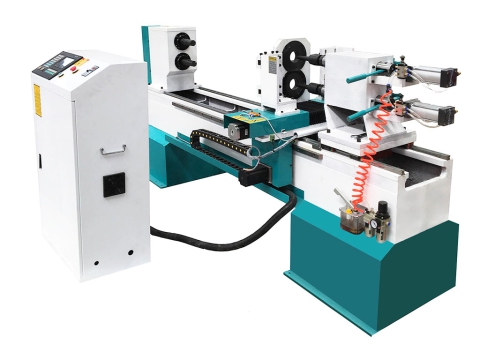

A wood lathe is a woodworking machine tool that uses a woodworking turning tool to process a rotating surface of wood or a complex profile.

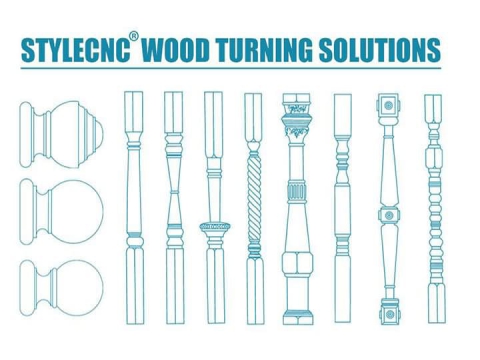

Wood lathes are mainly used for processing various stair columns, roman columns, table and chair legs, wash basins, wooden vases, wooden column tables, sticks, wooden furniture, children's bed columns, etc. It can also process plates, stemware, bottle caps, caps, caps, handles, rolling pins, flutes, flutes, suona, cello accessories, etc. CNC wood lathe is especially suitable for mass production of small and medium-sized woodworking enterprises. It can flexibly set the shape at any time and quickly change the processing style. In traditional lathe processing, only one product can be processed at a time. The CNC wood lathe has two-axis, two-axis and three-axis CNC wood lathes, which can process two or three products at the same time, with the same size and size. The operation is simple, the drawing is convenient, and it is easy to understand. The product style of one-key conversion, no professional knowledge personnel can conduct a little training. The fully automatic CNC wood lathe can operate 2-3 sets at the same time, greatly improving the processing efficiency, saving labor, saving money, and bringing good economic benefits.

Instructions

1. Check the tool tightening. Check whether the electricity, gas, machining area, etc. are normal and the workpiece is clamped.

2. Before machining, confirm that the program input is correct, the tool setting is correct, and the system parameters are reasonable.

3. Turn the knob to "Automatic", then select the plan to be processed and press the "Cycle Machining"

4. The equipment begins to return to the mechanical zero point to prepare for machining.

5. Press "Cycle Machining", the equipment starts to run, the spindle rotates (if the tool table has started to feed, and the spindle does not rotate, click the "S

tart" key) to adjust the speed: the speed can be adjusted according to the material and machining shape of the workpiece Depending on the tool, in general, the hard speed is higher. Normal soft speed is sufficient. When the workpiece vibrates during the machining, the speed should be adjusted appropriately to eliminate the vibration.

6. The system will automatically return to position after machining.

7. Change the blank while continuing machining, just press the "Cycle Machining" button. When the program needs to be changed, repeat the above actions.

8. If you exit the machining program, directly press the "Exit" key, or turn the knob to "Settings", it will return to the initial interface.

9. If errors are found during machining, you can press "Emergency Stop", the program will stop all actions. If you just stop to view, press the pause button to stop, press the pause button to continue machining.

Please note that it is best to use a low speed for the feed during the process, use the "empty" speed when retracting or not machining the feed, use the fast feed for smooth sections, and use the small speed for the sections with large diameter changes. It is better to cut the large-diameter section to the small-diameter and small-speed cutting section for the sudden change or large change.

Precautions

1. Do not install the device during lightning or thunder, do not install the power socket in a humid place, and do not touch the uninsulated power cord.

2. The operator on the machine must go through rigorous training and must pay attention to personal safety and machine safety during the operation process, and operate the computer numerical control wood lathe in accordance with the most operating procedures.

3. The power supply voltage requires 220V / 380V, and the fluctuation is less than 5%. If the power supply voltage is unstable or there are high-power electrical equipment around, please choose a regulated power supply under the guidance of professional technicians.

4. The CNC wood lathe machine, the control cabinet must be grounded, and the data cable cannot be plugged in while it is live.

5. The operator must not wear gloves to work, it is best to wear protective glasses.

6. The body of the machine is a casting, which is relatively brittle. When installing the screw, the force should be appropriate to prevent slipping.

7. The tool must be installed and clamped to keep the tool sharp. The blunt tool will reduce the turning quality and overload the motor.

8. Do not put your fingers into the working range of the tool, and do not remove the turning head for other purposes. Do not process materials containing asbestos.

A

9. Do not exceed the mechanical machining range. When the machine is not working for a long time, cut off the power supply. When the machine moves, it must be carried out under the guidance of professionals.

10. If the machine is abnormal, please refer to the operation manual for troubleshooting methods or contact the dealer to solve it; so as not to cause human damage.

Safety Rules

1. Before operating the CNC wood lathe machine, the workpiece should be firmly installed, the tailstock fixing nut should be tightened, the thimble should be locked with a locking device, the workpiece should be rotated by hand, and the position of the tool holder should be adjusted and fixed. 2 ~ 3mm, the distance between the tool holder and the workpiece is too large, it is easy to pierce the knife, causing a safety accident.

2. After the wood is clamped, the chuck must be turned by hand to calibrate, and check whether the screw of the knife bar and the top of the knife holder is firm, and then turn on the power to test.

3. For long materials over 100mm, the top of the tailstock must be used to hold it firmly.

4. When installing a tool for a CNC wood turning lathe machine, the length of the tool bar extending from the tool holder should be shorter than 50mm, and the length of the tool bar should be kept at 150mm. When machining a large workpiece (diameter above 500mm), the tool must be fixed on the tool holder The knife should be clamped firmly, and the knife should not be too sharp.

5. The amount of knives should be appropriate. When rough turning, the amount of knives should be smaller because of the corners of the workpiece. After the corners are turned, the rotation speed can be increased after the basic turning. /turn.

6. Keep the cutting edge of the turning tool sharp and use a blunt tool to turn the workpiece, which affects the quality and is prone to accidents.

7. Small workpieces have knots and cutting is not allowed. When the workpieces have knots, fast trains are not allowed, and other hard things in wood should be removed in time, otherwise machining is not allowed.

8. When CNC wood lathes are used to turn irregular wood with corners, the corners should be cut with a fixed turning tool first, and then used for fine machining.

9. Grinding the surface of the car parts with sandpaper can improve the surface smoothness. The hand pressure of the sanding should not be too large. The sandpaper should move at a uniform speed along the surface of the workpiece to achieve the grinding of the workpiece without causing excessive wear on the workpiece.

10. When turning the first cutter on a CNC wood turning lathe machine, the amount of feed should be small. When polishing with emery cloth or sandpaper, the right hand must be in front and the left hand is behind, and the force should be even.

11. When turning glue to bind wood, it must be placed for 24 hours before machining on the lathe;

12. The rotation speed of the CNC wood lathe machine depends on the external dimensions and material of the machined parts.

13. Choose a good spindle speed, turning large workpieces, the speed should be moderately slow, because large workpieces have a large inertia when rotating, fast turning, easy to accidents, when turning small workpieces, the speed can be appropriately faster, turning speed is fast, easy To obtain smooth workpieces, it is important to note that before turning the rough workpiece, the edge of the wood must be cut into a circle, and the square bar must not be turned straight, otherwise it may cause accidents.

14. Strictly abide by the safety operation rules of the CNC wood lathe. Before starting the lathe, check whether all parts are normal before operation

15. How to maintain CNC wood lathe?

Maintenance Rules

CNC wood lathes must be inspected and maintained before and after operation. The following are the specific maintenance rules:

1. Lubricating effect of lathe In order to ensure the normal operation of the lathe, reduce wear and prolong the service life, all friction parts of the lathe should be lubricated, and pay attention to daily maintenance.

2. Oil pump lubricating: It is often used in the continuous forced lubrication mechanism with high speed and large amount of lubricating oil. This method is used for many lubrication points in the spindle box.

3. Commonly used lathe lubrication methods lathe lubrication takes many forms. Commonly used are the following:

A. Pouring oil lubrication: commonly used for exposed sliding surfaces, such as the slide rail surface of the bed rail surface.

B. Oil splash lubrication: It is commonly used in closed boxes. For example, the turning gear of a lathe spindle box spatters the box bottom lubricating oil to the upper oil tank of the box, and then flows to each lubrication point through the oil holes in the tank for lubrication.

C. Oil-line lubricating oil guide: It is commonly used in the oil sump of the feed box skid box. The oil-line is easy to absorb oil and easy to leak oil, and the oil is introduced into the lubrication point through the oil-line to intermittently drop oil for lubrication.

D. Oil filling and lubrication of the billiard oil cup: It is commonly used in the bearing of the tailstock, the rocker handle of the skateboard and the tripod (screw, light rod, operating rod) bracket. Press the oil nozzle at the end of the oil gun regularly to press the marble on the oil cup to inject oil. The grease nipple was removed, and the marble returned to its original position. The oil filler was sealed to prevent dust from entering.

E. Lubricating grease cup: It is often used for exchanging gearboxes, exchanging shafts between gear frames or places where it is inconvenient to lubricate frequently. The butter cup is filled with calcium-based grease in advance. When lubrication is needed, screw in the oil cup cover and the cup grease will squeeze to the lubrication point.

After the above maintenance, the CNC wood lathe can be more convenient to use, and the service life can be extended.