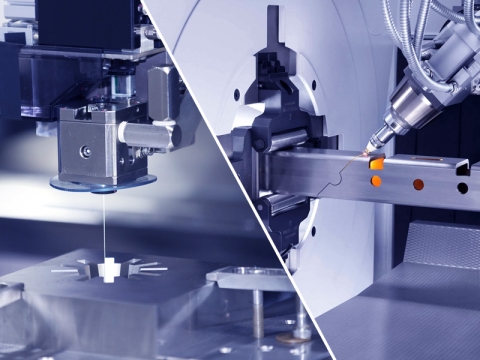

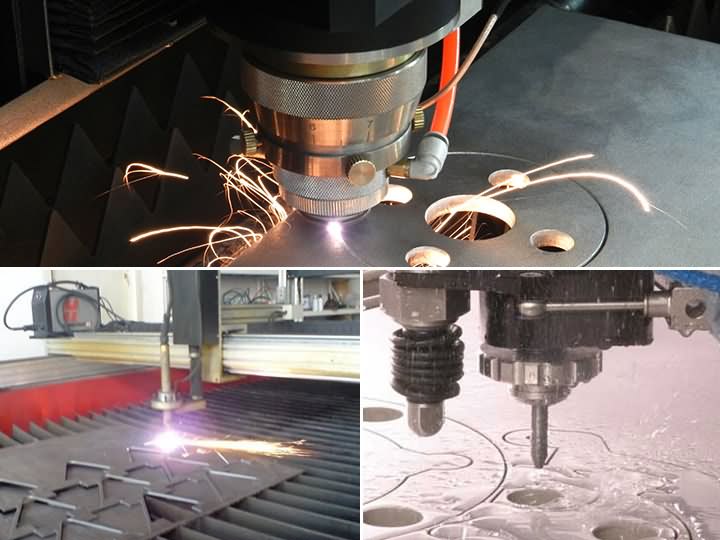

There are several types of non-traditional equipment that could be useful for CNC cutting application, such as laser cutting machine, plasma cutting machine and abrasive waterjet machine.

Abrasive waterjet machining is extremely noisy. It has high consumable and maintenance costs. It could also be messy due to the fact that abrasives and water used in this process could rebound. Though abrasive waterjet machining has many advantages such as low mechanical and thermal damage to the workpiece, minimal burr production during the process. due to the fact that it was messy and had high maintenance and consumable costs.

Thus, plasma cutting machine and laser cutting machine were widely used, and what are the differences between them?

To determine the best-suited machine for CNC cutting application, the following criteria were considered:

1. Process capability to ensure part accuracy. The manufacturing process should be efficient enough to handle batch production with high repeatability to manufacture parts with required tolerances. The process should be flexible for manufacturing parts of various thicknesses without any significant loss of time

in tool changes. The parts manufactured should require minimum or no secondary operations for finishing like deburring or grinding. The process should have minimum setup times. The process should also have a safe and clean work environment.

2. Fast and reliable unmanned operation. The process should be automated in order to reduce labor. Non value added operations like material handling (loading and unloading) should be minimum. The scrap handling or disposal should be efficient. The process should be safe and reliable. Ease of use is an issue as training and retraining costs should be low.

3. Operating costs should be less. The operating costs to run and maintain the equipment should be relatively low. The initial costs of the equipment will evidently affect the operating costs. There are various factors that could affect the operating costs. Cutting speed, consumable costs and maintenance costs are a few of the factors. In order to have low operating costs, cutting speed should be high, consumable and maintenance costs should be low.

Companies of plasma cutting machine and laser cutting machine addressed CNC cutting current process and application. Sample pieces of different material thickness were cut using both plasma and laser. The observations were:

1. Lasers have one third the operating costs of fine plasma.

2. Superior cut quality with the laser.

3. Cutting time is shorter with fine plasma.

4. Cutting speed drastically decreases for thicker materials with a laser.

5. Fine plasma can cut thicker material (1/2 to 1) faster and efficiently without cutting edges being affected.

6. Consumable costs with a laser is 1/6th the costs of fine plasma.

7. Better aesthetics with a laser including cleanliness.

The comparison is tabulated in table 1.1. Looking at the comparison, it was decided that a laser cutting machine is better suited for CNC cutting application.

Plasma cutting machine vs Laser cutting machine

| Selection Criteria | Laser cutting machine | Plasma cutting machine |

| Machine cost | - | + |

| Material Handling | + | 0 |

| Consumable costs | + | - |

| Cutting speed | - | + |

| Operating costs | + | - |

| Material thickness | 0 | + |

| Service | N/A | N/A |

| Aesthetics (includes cleanliness) | + | 0 |

| Secondary operations (for cutting thicker material) | + | 0 |

| Total | 2 | 1 |

Table 1.1: Comparison between plasma cutting machine and laser cutting machine