Laser metal engraving machines represent the most advanced tools intended for precise and permanent marking of metals. They use focused beams of laser energy to trace designs, text, or patterns with great accuracy. These machines have been in common usage for manufacturing, jewelry, and space industries due to their unbeatable speed and versatility.

Modern laser engraving systems bring a lot of advantages over traditional methods. They allow for non-contact engravings that preserve the integrity of the material while achieving highly detailed results. With advanced integration of software, users can customize intricate designs with ease; hence, these machines are ideal for both industrial applications and creative projects.

These machines come in different forms, including fiber lasers, which are incredibly effective at working with metals like steel, aluminum, and brass. As advancements in laser technology continue, metal engraving machines have become an essential tool for companies looking to achieve accuracy and speed.

How Much Does Laser Metal Engraving Price in the USA?

The cost of laser metal engraving machines in the USA can vary significantly because it depends on type, power, brand, and application. These machines are employed in various uses, ranging from small projects for hobbyists to industrial-level engraving for professional users. A detailed breakdown of the average pricing across popular brands is shown below.

STYLECNC

STYLECNC is one of the well-acknowledged suppliers of fiber laser engraving machines in the USA, and prices start at $2,400. Their machines boast a good reputation for being very precise, efficient, and reliable; thus, perfect for small enterprises and professionals. Depending on the specification of the machine, it could increase to $20,000 or higher for high-power and industrial-grade models. STYLECNC offers great value in the middle-range segment and meets various budgets and needs.

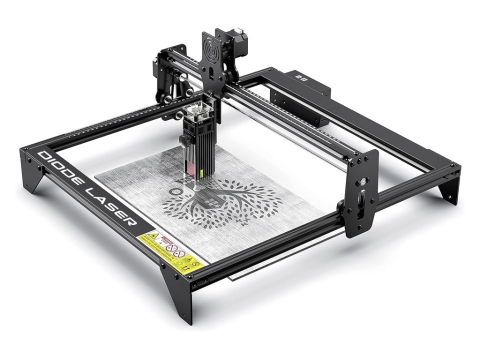

xTool

xTool specializes in smaller-scale engraving solutions, with entry-level diode laser engravers starting at $629. Higher-powered CO2 models are priced up to $4,000, catering to users needing more robust capabilities. Their machines, particularly with additional attachments, are capable of intricate engraving on softer metals, making them a great fit for DIY enthusiasts and small businesses. xTool focuses on user-friendly machines that are efficient and portable.

Boss Laser

Boss Laser offers a series of machines to meet small business and industrial users' needs. These range in price, starting from $3,500 into the high-end, with prices as high as $30,000. With the exceptional quality of the machines themselves, Boss Laser machines are widely preferred by their customers, providing highly efficient, large-format engravings and cuttings at faster speeds with more accuracy.

Glowforge

Glowforge is synonymous with ease of use, with prices beginning at $3,995 for their CO2 laser engravers. These machines are particularly suitable for hobbyists and small businesses focusing on coated or anodized metals. Glowforge stands out for its seamless operation, creative design flexibility, and compatibility with various software, making it ideal for first-time users or smaller-scale applications.

Epilog Laser

Epilog is a premium brand offering both fiber and CO2 laser engravers, with entry-level prices starting around $8,000. Industrial-grade models can exceed $40,000, delivering unparalleled durability, precision, and advanced features. Epilog machines are widely used by professionals requiring intricate engraving on metals, offering long-term value through exceptional performance and robust technical support.

Thunder Laser

Thunder Laser provides high-performance, industrial-use machines that range in price from $6,000 to $25,000. Its versatile systems can engrave and cut a wide variety of materials, even metals. Thunder Laser has earned a reputation for consistently strong performance and solid build quality. It is popular with many businesses that need to deliver with consistency in the harshest of environments.

Depending on the needs and budget, a laser metal engraving machine is either for a hobbyist or a professional. Starting at $2,400, one can get affordable machines like STYLECNC, while high-end brands like Epilog cater to industrial users, with machines well over $40,000. A good machine provides the needed precision, reliability, and capability to work on a wide range of engraving projects.

Factors That Affect the Cost of Laser Metal Engraving in the USA

The cost of laser metal engraving machines in the USA is very different, depending on a number of important factors. Being aware of these elements will enable buyers to make informed decisions when choosing the right machine for their needs. Be it a small business or an industrial manufacturer, all these factors are very crucial in terms of the overall investment.

1. Type of Laser Technology

It involves the type of laser technology, like fiber, CO2, or diode, which affects cost. Fiber lasers are typically the most expensive, starting around $2,400, owing to their high efficiency in engraving even hard metals such as stainless steel. The price is lower for CO2 lasers, but they should be used on coated metals or softer materials.

2. Power Output

Laser power, measured in watts, determines the engraving speed and depth. Machines with higher wattage are more expensive because they handle intricate or industrial-grade tasks. For instance, a 30W laser may cost less than a 100W industrial machine designed for faster, deeper engravings.

3. Build Quality and Components

High-quality components, such as advanced laser heads, precision optics, and durable frames, add to the cost. Brands like Epilog and Thunder Laser, known for their robust construction, tend to be pricier than entry-level machines.

4. Machine Size and Work Area

Larger machines with expansive work areas, like 4x8 feet, are ideal for big projects but come at a higher price. Compact models for small-scale engraving are more budget-friendly.

5. Software and Automation

Advanced control systems and automation features like auto-focus and material detection increase costs. Machines with user-friendly interfaces, such as Glowforge or xTool, often appeal to beginners but might lack industrial-grade features.

6. Brand Reputation

Renowned brands like STYLECNC, Boss Laser, and Epilog offer higher-priced machines backed by customer support, warranties, and quality assurance. Cheaper, lesser-known brands may lack these benefits, impacting reliability.

Each of these factors contributes to the price range of laser metal engraving machines. Balancing your needs with budget constraints ensures a cost-effective investment in a reliable and efficient machine.

Is Laser Metal Engraving Affordable for Small Businesses?

Laser metal engraving has become a feasible and cost-effective solution for small businesses, thanks to a variety of accessible models and flexible pricing options. These machines provide high precision and versatility, making them an excellent investment for improving production capabilities.

Entry-Level Options

The basic laser engravers by STYLECNC and xTool begin at an approximate cost of $2,400. While designed with small-scale operations in mind, these machines will nevertheless give reliably good service for general engraving applications. In the case of a company on a tight budget, they offer an accessible starting point, being able to be upgraded when the demands of the business increase.

Cost Efficiency

Investing in a laser engraver allows businesses to reduce or eliminate outsourcing costs. By completing engraving tasks in-house, companies save on labor and transportation expenses while increasing production efficiency. Over time, this cost-saving contributes to a faster return on investment (ROI).

Versatility for Diverse Applications

Laser engravers can work with various materials, including metals, coated surfaces, and plastics. This helps small businesses diversify their offerings-from creating customized products like metal plaques to crafting intricate designs on jewelry-such flexibility ensures the equipment pays off by expanding revenue streams.

Financing Opportunities

For businesses concerned about the cost upfront, many brands offer financing plans, leasing options, or monthly installments. This way, small businesses can have quality machines without necessarily straining their finances; hence, laser engravers become more accessible to growing companies.

Long-Term Savings and Durability

Modern laser engravers are built to last, requiring minimal maintenance. While the initial purchase might seem significant, the machine's durability and low operating costs make it an affordable, long-term solution for small businesses looking to optimize their workflow and boost profitability.

How to Choose the Right Laser Metal Engraver for Your Budget?

Buying an ideal laser metal engraver requires caution while considering the needs, budgets, and machine abilities. Be you a small business entrepreneur, hobbyist, or industrialist manufacturer, a well-made choice means better return on your investments.

Identify Your Needs for Engraving

Determine what engraving projects you will handle first. For hobbyists, small and low-power models that are affordable and meant for finer details could be used. Companies dealing with numerous orders at once may need a high-power engraver to work effectively. Knowing your volume of production and type of materials you will deal with helps in narrowing down the search.

Understand Machine Specifications

Examine key specifications such as laser power, engraving speed, and bed size. Higher wattage is necessary for cutting thicker metals, but for fine details, even a lower-powered machine can deliver excellent results. Additionally, ensure the machine supports your target materials, as some models specialize in metals, while others work better with mixed materials.

Compare Brands and Prices

Research brands like STYLECNC, Boss Laser, and Epilog Laser, which have a range of options to fit most budgets. STYLECNC provides more affordable options, starting at $2,400, while industrial-grade models from Boss Laser or Epilog may cost as much as $40,000. Pay close attention to their customer reviews, warranties, and support services to select a brand that meets your budget and quality expectations.

Check Additional Costs

In addition to the upfront cost, add the costs of maintenance, software, and add-ons. For example, a rotary attachment for engraving cylindrical items or a cooling system for high-power lasers can increase your overall costs. Anticipating these extra costs avoids surprises later.

Consider Financing Options

If the upfront cost is an issue, check for brands that offer financing or leasing plans. In this way, you will be able to use the high-quality machine and split the price with manageable payments.

Maintenance Costs for Laser Metal Engraving Machines

Maintenance of a laser metal engraving machine is generally linked with regular expenses, which allow the machine to serve longer and work effectively. The main consumables include lenses, mirrors, and filters, which might cost in a range from $50 to $300 depending on the model of the machine. The cooling system needs periodic maintenance, such as changing the water or antifreeze, which costs around $30 to $100 per year.

Software updates or subscriptions may also be added to the cost, especially for more complex systems that involve proprietary software. Energy consumption and electricity costs also depend on the power of the machine, ranging from $10 to $50 per month for small to mid-sized machines. Preventive maintenance involves cleaning optics and lubricating moving parts to minimize breakdowns and extend the life of the machine. These are minor but recurring investments.