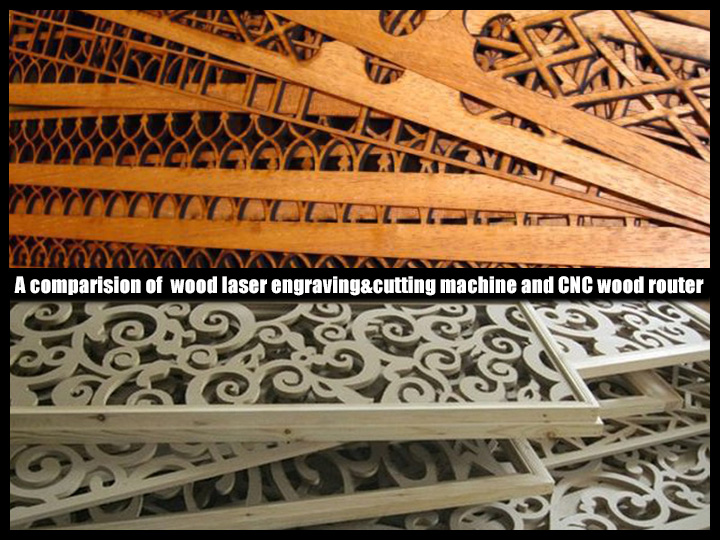

Laser wood engraving and cutting machine is the most powerful CNC machine. The machine has it's own advantages, Wood laser engraving and cutting machine can be used to the advertising industry, wood industry, arts and crafts industry, etc.. Some customers make wood products with Wood laser cutting machine, but many woodworking industry customers still choose CNC wood router, Wood laser engraving machine is known as universal engraving and cutting machine, but wood laser cutting machine for wood products processing is not as good as CNC wood router processing effect after all.

Technical methods for wood cutting materials by Wood laser cutting machine:

Performance of gray scale:

CNC wood router can not engraving and cutting in the economic way of the point, and thus does not have the form of gray. Wood laser engraving and cutting machine is a way to achieve the engraving, with the natural advantages in the gray level performance. To this end in the design of the sculpture as far as possible in the form of gray scale, such benefits are reduced in the coloring process, saving costs; on the other hand, a wealth of expressive means to increase the level of graphics. Users in the use of graphics to do a different gray fill (text to first transform the graphics), the output selection of black and white, you can try the effect of different outlets, the accuracy is generally not more than 500dpi.

Carving material:

Log (untreated wood)

Wood is the most commonly used laser engraving and cutting materials, it is easy to engrave and cut. Light wood like birch, cherry or maple very easily by laser vaporization, which is suitable for engraving and cutting. Each wood plate production has its own characteristics, some of the dense, such as hardwood, in the engraving or cutting when it is to use a greater laser power. We recommend that the engraving is not familiar with the wood before, to first study the characteristics of the carving.

Plywood:

There is not much difference in the plywood engraving and cutting, but there is a point to pay attention to, the engraving depth can not be too deep. The plywood edge will be blackening after engraving and cutting, the keypoint is to see the use of plywood manufacturing.

Wood engraving:

Generally speaking, the wood engraving is intaglio, and the depth of the general requirements is more deeper. Such power is generally higher, The color of the carved graphics will become deeper if encountered a more hard wood. If you want to make a lighter color, you can increase the speed of engraving, try to make more than a few times. Some wood engraving will make fumes to be attached on the surface of the wood, The fumes can be wiped by wet cloth if the wood has brush paint, and the fumes will not be wiped completely if not painting, The result is the fouling of product surface.

To color:

There will be a burning feeling after wood engraving, with wood color match is a kind of primitive art beauty, the color depth mainly depends on the laser power and the speed of engraving. But some wood is usually a soft kind, no matter how you can change its color (such as birch). The finished color, can use acrylic paint.

Wood cutting:

The cutting depth of the wood by Wood laser cutting machine is not deep generally, maximum cutting depth depends on the wood materials and laser power, such as to be very thick wood cutting, the cutting speed can be slowed, but this may cause wood burning. The specific operation can be used to try to use a large size lenses, and repeat cutting.