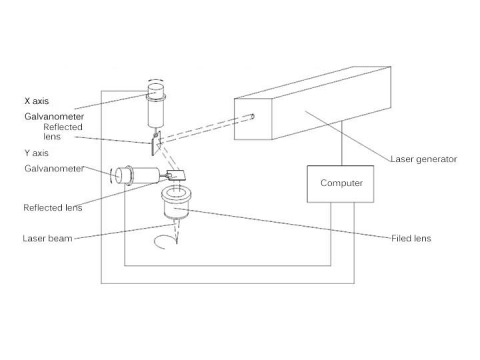

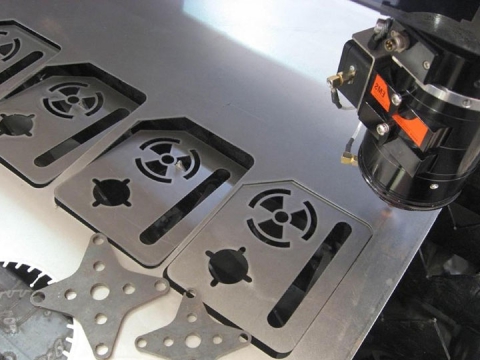

Laser cutting is an automatic thermal cutting method for processing metal, wood, MDF, plywood, acrylic, plastic, fabric, leather, and paper. The laser beam is created by the laser source (resonator), conducted by a transport fiber or mirrors in the cutting head where a lens focuses it at very high power on a very small diameter. This focused laser beam meets the surface of the substrate and melts it to get the cutting done. There are two types of laser sources: fiber laser and CO2 laser. Laser cutting is extremely versatile. In addition to flat materials, tubes and profiles can also be cut by laser cutting systems.

Fiber Laser Cutting Machine

A fiber laser is a solid-state laser with an optical fiber as the laser gain medium, consisting of a gain medium, a pump source and a resonant cavity. Fiber lasers use active fibers doped with rare earth elements in the core as the gain medium. A semiconductor laser is used as the pump source. The resonant cavity is generally composed of mirrors, fiber end faces, fiber loop mirrors or fiber gratings.

According to the time-domain characteristics of fiber lasers, they can be divided into continuous and pulsed fiber lasers. According to the structure of the resonator, it can be divided into linear cavity, distributed feedback, and ring cavity fiber lasers. According to the difference of gain fiber and pumping method, it can be divided into single cladding (core pumping) and double cladding (cladding pumping) fiber lasers.

CO2 Laser Cutting Machine

A CO2 laser(carbon dioxide laser) is a gas laser that uses a mixture of gases as the gain medium, including carbon dioxide, helium, nitrogen, and possibly some hydrogen, water vapor, and xenon. The laser is electrically pumped by a gas discharge, which can be used with DC current, AC current or in the RF range. The nitrogen molecule is excited by the discharge current to a metastable state, and then transfers energy to it when it collides with the CO2 molecule. Helium can reduce the number of low energy state particles and can remove the generated heat.

CO2 lasers usually radiate beam at a wavelength of 10.6 μm, but there are other radiation lines in the 9-11 μm period (especially 9.6 μm).

Medium

CO2 lasers use gas as the medium to generate the laser beam, and transmit the beam through mirrors. Fiber lasers are delivered through diodes and fiber optic cables, multiple diodes are pumped to generate a laser beam, and then transmitted to the laser cutting head through fiber optic cables, instead of transmitting the beam through mirrors.

Wavelength

CO2 laser is a type of gas laser beam with a wavelength of 10.6 μm from carbon dioxide molecules, while fiber laser is a type of solid-state laser with a wavelength of 1.08 μm, which is obtained by placing a crystal of Yb (ytterbium) compound as a medium in an optical fiber and irradiating the crystal with the laser beam. Due to the different physical features of the two types of lasers, the cutting processes are also different.

Photoelectric Conversion Efficiency

A fiber laser cutting machine adopts a complete solid-state digital module and a single fiber laser design. The photoelectric conversion efficiency is higher than that of CO2 laser cutting. The actual total utilization rate of each power supply of the CO2 laser cutter is about 8%~10%. The total utilization rate is about 25%~30%, and the total energy consumption of the fiber laser cutting system is 3~5 times lower than that of the CO2 laser cutting system, which has increased by more than 86%.

Investment Cost

The main cost of purchasing a laser cutting machine depends on the brand and power of the laser generator, as well as the core optical components. A CO2 laser cutter costs anywhere from 2,600 US dollars in the world, and the price of a low-power fiber laser cutter starts from 16,800 US dollars, while some high-power lasers will cost as high as 160,000 US dollars.

Maintenance Cost

Due to the purity of the CO2 gas, the cavity will become contaminated and require regular cleaning. Mirrors require maintenance and alignment, so routine maintenance is more involved. But the fiber laser cutting machine is maintenance-free, capable of harsh working environments with a high tolerance to dust, vibration, impact, humidity, and temperature.

Applications

Different materials to be cut have different light absorption rates for different laser wavelengths. Non-metallic materials (such as wood, fabric, plastic, acrylic, paper, leather) have a low absorption rate for fiber lasers, while CO2 lasers have high absorption rates for metallic or non-metallic materials. Fiber laser is only suitable for cutting metal materials, while CO2 laser can cut both metal materials and non-metal materials.