I purchased the STM1325-R3 a couple of months ago and other than testing it briefly, just got it up and running. I previously had another CNC machine that gave me all kinds of grief so this is my second one. This 4x8 CNC router came very well boxed and packed. Assembly was easy as it came as mostly assembled modules. All of the tools and bits required were included as well as a few accessories. The included software was pretty typical of any of these machines but certainly adequate to upgrade my woodworking shop. WHAT A DIFFERENCE! This machine is more stable and smooth. Some people seem concerned with the weaker spindle motor but I have not had any issue with it cutting anything of reasonable size so far. The spindle motor is a beast compared to my last one. It is so smooth and powerful that I purchased an ATC CNC router kit (STM1530C) made by STYLECNC that comes with a 5x10 worktable. (I will review it later). I am so glad that I spent the extra money to get this full-size CNC machine. It seems like a very capable tool for the value.

Customer Experiences With CNC Machines & Services

Don't take our words as everything. Find out what customers say about our CNC machines they have owned or experienced. Why is STYLECNC considered a credible brand and manufacturer to buy a new CNC machine? We can talk all day about our quality products, 24/7 excellent customer service and support, as well our 30-day return and refund policy. But wouldn't it be more helpful and relevant for newbies and professionals alike to hear real-life customers experience what it's like to purchase and operate an automatic machine tool from us? We think so too, which is why we've collected tons of genuine feedback to help bring transparency to our unique CNC machine buying process in-depth. STYLECNC guarantees that all customer reviews are real evaluations from those who have purchased and used our products or services.

The VMC855 operates efficiently and serves my automotive parts manufacturing business very well. I am delighted to own this CNC vertical machining center at a favorable price and look forward to its even better performance in the future.

Got my eagerly anticipated LCW1500 today, and I have to say, it really amazed me. This multi-functional handheld laser machning gun is incredibly powerful, combining cutting, welding, and cleaning capabilities, allowing me to experiment with a wide variety of metalworking techniques. Its portable design makes it flexible and easy to move around, making it convenient for me to perform various indoor and outdoor projects anytime and anywhere. The built-in touchscreen controller is user-friendly and easy to operate, even for beginners like myself. Its advantages are self-evident, but there's also something that bothers me - understanding the software's working parameters (such as laser power and material properties) to handle different metal fabrication processes requires a steep learning curve and repeated experimentation to find out the optimal settings. All in all, it's an absolute must-have for all amateur metalworking enthusiasts.

I've wanted a laser cutter for a long time and finally got one when it went on sale with STYLECNC China National Day Deals. I was thrilled to finally receive it today after a 10-day wait. Everything was as expected. Out of the box and together without any issues. Easy to set up and operate for a beginner like me. My first cut was through 1/8-inch-thick plywood for an alphabet puzzle, working like a hot knife through butter, saving a lot of time compared to using a scroll saw. It took practice to learn the cutting thickness, speed, and power settings, but now I'm looking forward to using it for other jigsaw puzzles. All in all, it's perfect for my DIY jigsaw business. I really wish I had bought this STJ1390 years ago.

The STM1325C arrived well packaged and exceeded my expectations. Mechanically, this CNC machine is well-built, with all parts pre-assembled. Assembly was pretty painless - I had it unboxed and put together in about half an hour following the included manual. The CNC controller software is user-friendly, and is easy to operate for anyone, whether beginner, intermediate or experienced. After a week of testing, this STM1325C has proven itself to be an excellent choice for woodworking automation, particularly cabinet making. I was also impressed by its linear ATC kit, which automates tool changing, freeing my hands while increasing productivity. In my personal experience, this is a quality CNC router worth buying.

This vertical mill is fantastic! After six months of use, it's still running like new, fast, precise, and powerful. I'm extremely satisfied with the high performance of this CNC machine and the prompt after-sales service.

I wanted something smart and budget-friendly to cut steel pipes for my projects and voila, here I'm with the most cost effective fiber laser cutting machine you can find. This laser did a great job shaping 1/4 inch square and rectangular tubing, and I was totally taken a back by this cutter. The smart CNC controller software and automatic feeder made every process easy and convenient. No more working with a handheld plasma cutting torch. I can say goodbye to dangerous manual operations. Overall, the ST-FC6020T exceeded my expectations. However, the high initial investment puts it out of reach for small workshops and home users.

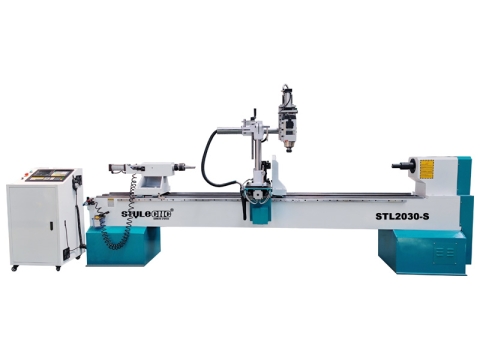

This lathe performs as advertised, boasting a heavy-duty bed frame and a wealth of features. I have been playing with it for a couple of weeks, turning dozens of table legs, and everything has lived up to my expectations - The STL1530A-7T operates flawlessly, and the milling spindle is impressive, allowing for personalized carvings on turnings. Furthermore, the CNC controller automates every capability, making it easy to balance quality and speed. This automatic feeder enables mass production and is a great partner for those committed to industrial mass manufacturing. So far, I'm 100% satisfied.

I went straight for a CNC lathe, despite having no previous manual turning experience. As a newbie, I was a little nervous at first, but the user-friendly controller made everything very easy to operate, without a hard learning curve, aside from the CAD software. However, this didn't bother me at all, as I already got all the vector files - my brother had created all the drawings for my business. All in all, it met my expectations and didn't let me down. I'm very satisfied with my choice.

I have worked in metal fabrication all my life and have done every cutting procedure except laser cutting. So, when I saw the hype about expensive fiber laser cutters on social media, I was skeptical, to say the least. After some research, I decided to purchase the ST-FC3015FM for my auto parts store, as my growing business required higher-precision metal cuts. Fortunately, it didn't let me down. Every cut was very smooth and clean, exactly as I expected. Also, make sure you order a safety light curtain as you need to keep yourself safe. All in all, this is an excellent laser machine for any metalworker on a budget.

This was my first time cutting marble with a CNC machine and was impressed by how great the waterjet cut. Every cut was clean and smooth, without dust like saw blade cutting. Exactly what I needed.

Bought it for my business of customizing tombstones of various sizes and materials. After comparing the pros and cons of CNC and laser for stone processing, I decided to go with CNC, as lasers couldn't achieve the engraving depth I required, nor could they cut the stone. After some research and exploration, watching YouTube videos, and reading reviews on Amazon and Google, I ultimately chose STYLECNC among many brands. However, shipping from China was a bit slow, and I waited almost a month to get it. As the saying goes, a good thing is never too late. The STS1325 is very easy to use for an experienced stonemason like me, but requires skills in CAD design and CNC programming. After over a month of commissioning and operating it, I would like to give it an objective and fair review. The 4x8 worktable easily processes full-size stone slabs, eliminating the need for pre-cutting and maximizing material utilization. The user-friendly software makes it easy for even CNC beginners to operate. Additionally, the water tank and cooling system prevent the spread of stone dust and debris. All in all, the STS1325 is a professional and ideal choice for stonemasons and small business owners looking for a powerful yet affordable stone CNC router machine.

I have been repairing and renovating the appearance and structural integrity of outdoor metal surfaces for 10 years, ranging from easy-to-handle patio furniture, fences, gates, siding, to complex driveways, car bodies, historical artifacts, and large metal buildings such as parking lots. I have used sandblasting tools, chemical rust removers, and even ultrasonic cleaners, none of which are perfect. I have been looking for a portable but powerful rust removal tool until the emergence of laser cleaning machines made me light up and decided to give it a try. It took 12 days for this handheld rust cleaning machine to go from STYLECNC to my workshop. Plug and play with a short learning curve, multiple rust removal modes are available, making it ideal to remove both light rust and heavy rust stains. I was very skeptical on how it would go before, but now I am amazed at its capabilities. What a great tool, well worth buying and highly recommended.

The VMC1160 has been running smoothly since I bought it, performing multiple operations in one setup. This vertical machining center is extremely convenient and efficient for my engine parts business, improving productivity while ensuring accuracy. I have to give it five stars.

I've used quite a few manual plasma cutters in the past, but this was the first time playing with a CNC so was a little overwhelmed. One of the metalworking forums I belong to had many recommendations for STYLECNC. Did a little research and decided to go with the STP1530R at less than 1/2 the cost of the fiber laser cutter with similar capabilities, capable of cutting both sheet metal and tubing (while plasma cutting is not as precise as laser cutting, it is more than adequate for my business). Arrived in 20 days, initial impression is good, the heavy-duty 5x10 full-size plasma table is sturdy enough, the rotary attachment accommodates a wide range of tubing, and the CNC controller looks very user-friendly. So far, I think it's a good buy, 100% worth the price. I will update the review with further use.

This laser cutter comes with all the features I would expect. CNC controller is intuitive and easy to use, with all settings visible at a glance. 2000 watt fiber laser is powerful enough to handle all my metal cuts with ease, smooth and clean without burrs. Impressively stable performance, with a full day of continuous cutting without any issues. One thing I have to say, if your budget allows, go for a closed enclosure, after all, the open bed is not a 100% safe option for laser guys. Overall, this is a great buy for the money, and STYLECNC is a reputable brand with dependable options.

Took me about two hours from unpacking to getting it up and running, after all, this is an advanced five-axis CNC machine, which is hard to get started for a novice, requiring sufficient knowledge of CAM controller software. Fortunately, I'm proficient in FANUC and Siemens control systems. If you're new to CNC programming, it may take longer. The instructions included were clear and easy to follow, and all tests went flawlessly. The only downside is that this unit is expensive and out of the budget of most CNC guys. All in all, great value for money in my opinion.

Bought this lathe for my high-end candlestick customization business. Received in 25 days, ready to use out of the box, no assembly required. Comes with all the parts and tools needed for turning. As an experienced carpenter I couldn't wait to play with it. After a month of use, I've turned a lot of items with this wood lathe, performing well without any trouble. With CNC, variable speed is no longer an issue. Everything goes smoothly, allowing you to enjoy the fun of woodturning easily without the need for hands. It's a pity that I didn't buy more blades as consumables with the machine (which would save me shipping costs), after all, tool wear is a big problem, and it's much cheaper to buy turning tools directly from Chinese manufacturers than from Amazon. If the extra budget is available, an additional dust collector is a must-have for cleaning up the excess wood chips. All in all, this is a great starter for wood turners who want to give automatic lathing a go. I would give the STL0525 a five-star rating and recommend it to all my fellow woodworkers.

I've been on the fence about buying a laser cutter to manufacture thicker sheet metal parts with precision, now and I finally decided to give the ST-FC3015FM a go. Arrived to my workshop in 30 days. Assembled in 45 minutes, easy to operate with a short learning curve. I've been experiencing this machine for a few months, I'm already up and running and have cut out a lot of metal parts, most of which turned out quite well. From thinner 1/16-inch stainless steel sheets to thicker 1/2-inch duralumin plates, the ST-FC3015FM can cut easily and produce smooth and clean cut edges. Its user-friendly CNC controller system seamlessly integrates with the CAD software I have been using, allowing for fast file transfer and real-time cutting parameter debugging. A full-size 4x8-foot mild steel plate with a thickness of 1/8-inch can be automatically cut into 24 metal parts in 36 minutes without additional manual operation, simplifying production process, improving quality and efficiency. I'm happy with my purchase and I'm motivated to continue with my new business of custom automotive and aerospace parts. However, the initial cost is higher for home users and small businesses, but it is worth the money. All in all, it is a must-have tool for large metal fabricators and a top choice for companies serious about growth to increase productivity.

Arrived in one week by air, plug and play, beginner friendly with a short learning curve in studying multiple cleaning modes. Tested on car parts and ancient coins, easily restored to original condition.

Pros

The portable design allows it to easily handle outdoor and indoor cleaning jobs.

The user-friendly control panel makes the rust removal process straightforward.

The laser is reusable and requires no consumables.

Cons

High initial cost but long term benefits compared to chemical rust removers and angle grinders.

The possibility of laser harm to the human body (safety goggles required).

Summary

The LC6000 fiber laser cleaning machine is an ideal solution for removing stubborn rust from metals, making rusty items look brand new again, without the need for scrubbing or sanding. If you're fighting rust, this tool tool is your top-tier choice.

I purchased the STM1325-R3 a couple of months ago and other than testing it briefly, just got it up and running. I previously had another CNC machine that gave me all kinds of grief so this is my second one. This 4x8 CNC router came very well boxed and packed. Assembly was easy as it came as mostly assembled modules. All of the tools and bits required were included as well as a few accessories. The included software was pretty typical of any of these machines but certainly adequate to upgrade my woodworking shop. WHAT A DIFFERENCE! This machine is more stable and smooth. Some people seem concerned with the weaker spindle motor but I have not had any issue with it cutting anything of reasonable size so far. The spindle motor is a beast compared to my last one. It is so smooth and powerful that I purchased an ATC CNC router kit (STM1530C) made by STYLECNC that comes with a 5x10 worktable. (I will review it later). I am so glad that I spent the extra money to get this full-size CNC machine. It seems like a very capable tool for the value.

The VMC855 operates efficiently and serves my automotive parts manufacturing business very well. I am delighted to own this CNC vertical machining center at a favorable price and look forward to its even better performance in the future.

The STM1325C arrived well packaged and exceeded my expectations. Mechanically, this CNC machine is well-built, with all parts pre-assembled. Assembly was pretty painless - I had it unboxed and put together in about half an hour following the included manual. The CNC controller software is user-friendly, and is easy to operate for anyone, whether beginner, intermediate or experienced. After a week of testing, this STM1325C has proven itself to be an excellent choice for woodworking automation, particularly cabinet making. I was also impressed by its linear ATC kit, which automates tool changing, freeing my hands while increasing productivity. In my personal experience, this is a quality CNC router worth buying.

This vertical mill is fantastic! After six months of use, it's still running like new, fast, precise, and powerful. I'm extremely satisfied with the high performance of this CNC machine and the prompt after-sales service.

This was my first time cutting marble with a CNC machine and was impressed by how great the waterjet cut. Every cut was clean and smooth, without dust like saw blade cutting. Exactly what I needed.

Bought it for my business of customizing tombstones of various sizes and materials. After comparing the pros and cons of CNC and laser for stone processing, I decided to go with CNC, as lasers couldn't achieve the engraving depth I required, nor could they cut the stone. After some research and exploration, watching YouTube videos, and reading reviews on Amazon and Google, I ultimately chose STYLECNC among many brands. However, shipping from China was a bit slow, and I waited almost a month to get it. As the saying goes, a good thing is never too late. The STS1325 is very easy to use for an experienced stonemason like me, but requires skills in CAD design and CNC programming. After over a month of commissioning and operating it, I would like to give it an objective and fair review. The 4x8 worktable easily processes full-size stone slabs, eliminating the need for pre-cutting and maximizing material utilization. The user-friendly software makes it easy for even CNC beginners to operate. Additionally, the water tank and cooling system prevent the spread of stone dust and debris. All in all, the STS1325 is a professional and ideal choice for stonemasons and small business owners looking for a powerful yet affordable stone CNC router machine.

The VMC1160 has been running smoothly since I bought it, performing multiple operations in one setup. This vertical machining center is extremely convenient and efficient for my engine parts business, improving productivity while ensuring accuracy. I have to give it five stars.

Took me about two hours from unpacking to getting it up and running, after all, this is an advanced five-axis CNC machine, which is hard to get started for a novice, requiring sufficient knowledge of CAM controller software. Fortunately, I'm proficient in FANUC and Siemens control systems. If you're new to CNC programming, it may take longer. The instructions included were clear and easy to follow, and all tests went flawlessly. The only downside is that this unit is expensive and out of the budget of most CNC guys. All in all, great value for money in my opinion.

Arrived in 25 days in excellent condition, well built, just as described, easy-to-follow instructions for assembly, setup and operation, took 45 minutes to get the first job started.

Pros:

• The 5x10 working table is sizeable to handle all of my woodworking projects.

• The main frame is very sturdy with great rigidity, and allows me to create precision carvings and cuts even for the larger items.

• The CNC controller software is easy to use for beginners.

• Excellent customer service, always prompt response at the first opportunity.

Cons:

• Too heavy and too large to carry to high-rise workshops.

• Not very compatible with other CAM software.

• CAD software basics are required for creating custom and complex designs.

• Shipping is a bit longer compared to local purchases.

Final Thoughts:

This full-size CNC milling machine with automatic tool changer is a must-have for businesses involved in manufacturing wood doors and cabinet furniture. The addition of industrial automation increases productivity and reduces labor costs. All in all, the STM1530C is worth the money.

The S1-IV is well designed for cabinet making, and the four spindles can be switched at any time to handle different jobs. This CNC router comes with good bones, and there is no flex in the frame. Tolerances are tight for precision woodworking. The controller software was installed on the computer that came with the machine. Easy to use after a short learning curve. The operation interface is user-friendly for beginners and smarter than any I've used before. Overall, I'm comfortable enough with this kit. However, it's a pity that the wood panels cannot be automatically loaded and unloaded. For someone as ambitious as me, an automatic feeder is a great option for panel furniture making, and I will have to upgrade it in the future.

After a month of anticipation, I got this CNC machine that I had been looking forward to. I was stunned the moment I opened the package. It was exactly what I expected. My doubts turned into surprises. Since I am a CNC programmer for woodworking, I experienced a short learning curve in software installation and operation. In terms of use, the STM1325CH works great with the automatic tool changing system, and can handle all of my woodworking projects for cabinet making. However, potential buyers should consider the initial investment as well as the operation and maintenance requirements, as this machine is a bit expensive and requires CNC skills from the operator and maintainer. Overall, the STM1325CH stands out for its performance and reliability.

I've always wanted a full-size CNC machine to make custom 3D wooden pillars for a while, but it was too expensive and out of my budget (my furniture store is just starting out). I was on the fence until my wife told me that I could buy a budget-friendly 3D CNC router from China at a low price that I could afford, even with shipping costs. After almost a month of exploration and research, I finally decided to give the STM1325-4 from STYLECNC a try (during which I sent my wood blanks for trial machining and got satisfactory carvings and cuts). The machine arrived about three weeks later in perfect condition. I finally let go of my hanging heart. After all, this was my first cross-border shopping. All that's left is how to play with it. I had no trouble getting it up and running since I am a CNC machinist. I tried milling four stair posts at a time, resulting in smooth and clean carvings, but the only drawback was the somewhat slow speed. Overall, this was a perfect shopping experience. I look forward to it creating more personalized woodworking projects and making my shop prosper.

I wanted a CNC router for woodworking, as well as a drag knife for cutting foam, cardboard, rubber, and some sealing materials, so I ordered the STM2030CO and so I did not have to purchase two machines. So far everything is running as expected. The only issue was the controller switching, so I reached out to STYLECNC tech support and they were responsive and did an excellent job of diagnosing and debugging the software in a timely fashion.

The setup is fairly easy with videos and instructions. The software is straightforward with a short learning curve for beginners. Heavy-duty bed frame, sturdy and well built. It's a bit of a shame that this workbench cannot be taken apart. I had to dismantle my exterior door to put it in. No doubt the table size is large enough to cut full 4' x 8' sheets of MDF and plywood with ease and precision, available for creating human-scale projects. Perfect for my woodshop. Overall, the full-size CNC router table kit is cheap but impressive, and more bang for your buck. Happy CNCing.

Intuitive operating interface, user-friendly and easy to use for beginners. I'm blown away by the performance of this small desktop CNC. I have built 12 relief carvings, turning out as well as expected. Overall, excellent value for money.

This is another good machinery by STYLECNC and arrived in good health. The manual made the assembly easy and working in top condition. This machine has been running well with no issues. I have been using it to make custom crafts for my new woodworking shop. I would recommend this kit to anyone looking to bring their creative ideas to life.

Got this 4x8 CNC 3 months ago and it has been an extremely satisfying experience. Came well packaged and was easy to assemble with instructions provided. Took about 2 hours to put all the parts together. So far I've cut and carved soft and hard wood with no issues, although it has a learning curve like all CNCs when it comes to getting the controller software up and running. I'm very pleased with the projects I have made and as I learn I will continue to build many more. The best thing about this buying from STYLECNC is their customer support. The response was prompt and timely, exceeding my expectations. The English-speaking technicians helped me a lot with the software settings, making it easy for me, a novice in CNC programming, to get started. Thank you. My only regret is that I didn’t add the automatic tool changer option when I purchased it, but I will upgrade in the future. This device will make the entire machining process much safer and more automated.

This is my first CNC router so there was a learning curve and a few hiccups. I am giving this kit a mixed review. Let's start with the good. STYLECNC's responsive technical support staff walked me through to figure out the problems and correct them. The machine itself is well built and exceeded my expectations. Easy to assemble. Fit is excellent with my cabinet shop. Perform well in cabinet furniture making all the time. What I have to mention is this automatic tool changing device, which frees my hands and everything is automatic and safe. Speaking of which, I can give the machine and customer service 5 stars. But unfortunately, the LNC CNC controller software only runs on Windows, without Mac and Linux support, which is a bit of a shame for me. Overall, I can only give it four stars.

Got my eagerly anticipated LCW1500 today, and I have to say, it really amazed me. This multi-functional handheld laser machning gun is incredibly powerful, combining cutting, welding, and cleaning capabilities, allowing me to experiment with a wide variety of metalworking techniques. Its portable design makes it flexible and easy to move around, making it convenient for me to perform various indoor and outdoor projects anytime and anywhere. The built-in touchscreen controller is user-friendly and easy to operate, even for beginners like myself. Its advantages are self-evident, but there's also something that bothers me - understanding the software's working parameters (such as laser power and material properties) to handle different metal fabrication processes requires a steep learning curve and repeated experimentation to find out the optimal settings. All in all, it's an absolute must-have for all amateur metalworking enthusiasts.

I've wanted a laser cutter for a long time and finally got one when it went on sale with STYLECNC China National Day Deals. I was thrilled to finally receive it today after a 10-day wait. Everything was as expected. Out of the box and together without any issues. Easy to set up and operate for a beginner like me. My first cut was through 1/8-inch-thick plywood for an alphabet puzzle, working like a hot knife through butter, saving a lot of time compared to using a scroll saw. It took practice to learn the cutting thickness, speed, and power settings, but now I'm looking forward to using it for other jigsaw puzzles. All in all, it's perfect for my DIY jigsaw business. I really wish I had bought this STJ1390 years ago.

I wanted something smart and budget-friendly to cut steel pipes for my projects and voila, here I'm with the most cost effective fiber laser cutting machine you can find. This laser did a great job shaping 1/4 inch square and rectangular tubing, and I was totally taken a back by this cutter. The smart CNC controller software and automatic feeder made every process easy and convenient. No more working with a handheld plasma cutting torch. I can say goodbye to dangerous manual operations. Overall, the ST-FC6020T exceeded my expectations. However, the high initial investment puts it out of reach for small workshops and home users.

I have worked in metal fabrication all my life and have done every cutting procedure except laser cutting. So, when I saw the hype about expensive fiber laser cutters on social media, I was skeptical, to say the least. After some research, I decided to purchase the ST-FC3015FM for my auto parts store, as my growing business required higher-precision metal cuts. Fortunately, it didn't let me down. Every cut was very smooth and clean, exactly as I expected. Also, make sure you order a safety light curtain as you need to keep yourself safe. All in all, this is an excellent laser machine for any metalworker on a budget.

I have been repairing and renovating the appearance and structural integrity of outdoor metal surfaces for 10 years, ranging from easy-to-handle patio furniture, fences, gates, siding, to complex driveways, car bodies, historical artifacts, and large metal buildings such as parking lots. I have used sandblasting tools, chemical rust removers, and even ultrasonic cleaners, none of which are perfect. I have been looking for a portable but powerful rust removal tool until the emergence of laser cleaning machines made me light up and decided to give it a try. It took 12 days for this handheld rust cleaning machine to go from STYLECNC to my workshop. Plug and play with a short learning curve, multiple rust removal modes are available, making it ideal to remove both light rust and heavy rust stains. I was very skeptical on how it would go before, but now I am amazed at its capabilities. What a great tool, well worth buying and highly recommended.

This laser cutter comes with all the features I would expect. CNC controller is intuitive and easy to use, with all settings visible at a glance. 2000 watt fiber laser is powerful enough to handle all my metal cuts with ease, smooth and clean without burrs. Impressively stable performance, with a full day of continuous cutting without any issues. One thing I have to say, if your budget allows, go for a closed enclosure, after all, the open bed is not a 100% safe option for laser guys. Overall, this is a great buy for the money, and STYLECNC is a reputable brand with dependable options.

I've been on the fence about buying a laser cutter to manufacture thicker sheet metal parts with precision, now and I finally decided to give the ST-FC3015FM a go. Arrived to my workshop in 30 days. Assembled in 45 minutes, easy to operate with a short learning curve. I've been experiencing this machine for a few months, I'm already up and running and have cut out a lot of metal parts, most of which turned out quite well. From thinner 1/16-inch stainless steel sheets to thicker 1/2-inch duralumin plates, the ST-FC3015FM can cut easily and produce smooth and clean cut edges. Its user-friendly CNC controller system seamlessly integrates with the CAD software I have been using, allowing for fast file transfer and real-time cutting parameter debugging. A full-size 4x8-foot mild steel plate with a thickness of 1/8-inch can be automatically cut into 24 metal parts in 36 minutes without additional manual operation, simplifying production process, improving quality and efficiency. I'm happy with my purchase and I'm motivated to continue with my new business of custom automotive and aerospace parts. However, the initial cost is higher for home users and small businesses, but it is worth the money. All in all, it is a must-have tool for large metal fabricators and a top choice for companies serious about growth to increase productivity.

Arrived in one week by air, plug and play, beginner friendly with a short learning curve in studying multiple cleaning modes. Tested on car parts and ancient coins, easily restored to original condition.

Pros

The portable design allows it to easily handle outdoor and indoor cleaning jobs.

The user-friendly control panel makes the rust removal process straightforward.

The laser is reusable and requires no consumables.

Cons

High initial cost but long term benefits compared to chemical rust removers and angle grinders.

The possibility of laser harm to the human body (safety goggles required).

Summary

The LC6000 fiber laser cleaning machine is an ideal solution for removing stubborn rust from metals, making rusty items look brand new again, without the need for scrubbing or sanding. If you're fighting rust, this tool tool is your top-tier choice.

I was starting from scratch so I required everything needed for turnkey start up. I worked primarily with plywood and sheet metals like stainless steel, aluminum, and brass. I had to look for a full-size 4x8 hybrid laser cutting table to handle my precise cuts of metal and wood, and after a month of exploration and research I decided to give the STJ1325M a try. With some luck, I received my dream machine 20 days after placing the order. Individually packaged laser tubes are easy to assemble and plug and play. The user-friendly control panel is beginner-friendly for me as well as someone new to lasers. After a few days of trial cutting, everything turned out just as I hoped, and overall this laser cutter is perfect for all my projects.

This machine is extremely stable and perfect for my job. I have been using this laser tube cutter for a month and it works just as expected. I use it to cut frames and all the metal tubes I use for fabrication and it performs much better than a plasma cutter. So far it can hold its own for metal tubing.

This is an amazing heavy-duty laser cutter, easy to use even with no experience, user-friendly for beginners, and can cut all types of metal tubing, whether it's steel or aluminum, the ST-FC12035K3 can handle it easily, making it a must-have cutting tool for every metal fabricator.

I am amazed at the quality of this laser metal cutting machine. When I powered it up and tested it out, I was impressed with its cutting capabilities and precision, performing well on thick metals (over 1 inch) with a fiber laser power of 6 kilowatts. The full-size 5x10 work table makes most sheet metal cuts feasible, and the fully enclosed protective cover allows safe metal cutting. All in all, great value for money.

The manual is minimal but the CNC controller is easy to use and drives a laser beam to cut through 1/4 and 3/8 steel sheet with ease, and voila I'm here and there is the most cost effective metal laser cutter you can pick.

Assembly takes about 30 minutes with all the parts put together, as most are built in, only connecting the wiring and controller is required. The small footprint is perfect for my jewelry store with a protective housing. The included english instructions is easy to follow for beginners, with a user-friendly control panel. I cut a Christmas ornament out of 22 gauge brass with great anticipation and it turned out perfectly with clean edges. I was impressed by its speed and precison. The fly in the ointment is that the ST-FC1390 cannot cut through thicker metals over 16mm due to the lower fiber laser power of 2000W - STYLECNC’s official explanation. I'll try try to test its limits with various thicknesses of metal. in the next week. All in all, the ST-FC1390 is a great laser metal cutter worthy of praise.

This laser cutter does what it is intended to do - cuts very clean shapes and outlines in sealing materials. It's budget friendly, and easy to operate for starters with precision and quickness. I have to say, the STJ1610-CCD is an ideal choice if you need to make seals or cut washers from rubber stock at a low cost.

This fiber laser engraver is perfect for my custom gun engravings of AR-15, carbine, shotgun, pistol, and short barrel rifle. Its performance and speed blew my mind away, creating crisp signs and logos in seconds. The standout feature of the STJ-50F is its outstanding accuracy and repeatability (multiple engravings are required to create a relief), which ensures complex and detailed deep engraving. The rotary attachment works great for engraving gun barrels. In addtion, the included EZCAD software is beginner-friendly, straightforward, easy to setup and use, no experience required. What I am not satisfied with is that the 12x12 inch working table is limited to those oversized engravings. I regret not thinking of buying a portable model with a handheld laser gun before purchasing it.

I started a home store for custom woodworking business 6 months ago and have been looking for a laser cutter to make 3D wood puzzles. After almost 3 weeks of research, the STJ1390 fits the bill perfectly. The 100W of CO2 laser power can easily cut most of the plywood in my shop. Another component I like is the housing, which comes with a light-filtering window to protect my eyes without goggles. The built-in vents are very professional and remove harmful fumes from combustion when engraving and cutting wood.

With a detailed manual, the STJ-30F is easy to assemble. Compact and portable design with a handheld laser engraving gun, easy to work with once you get over a short learning curve of the controller software. The user-friendly interface allows for easy operation for beginners. The 30W output power enables it to create fine engravings on most materials such as metals and plastics. This fiber laser engraver can be a precision marking tool for professional use. Faster and more precise compared to CO2 lasers. If you are new to laser, read the included safety precautions before engraving, and always wear goggles when operating, after all, laser is not friendly to your eyes. All-in-all, a good purchase for my business.

The LW1500A is a remarkable addition to my repair shop for metal joining jobs. This laser welder is portable with lightweight design, easy to move and use. Powerful enough to create clean, strong welds on steel and aluminum. However, the initial cost is higher compared to ordinary welders, and requires safety precautions, such as protective eyewear. Overall, this tool is excellent for professionals seeking versatility and quality in welding.

This laser cleaner is plug and play and works great in my auto repair shop. It fires a laser beam and ablates the rust, leaving the part surface clean in seconds. I appreciate its precision as it can target specific areas without damaging the substrate. I'm impressed by the multiple cleaning modes for different cleaning purposes. Expect better and stable performance. Anyway, long story short, it's a great value for those looking for a cleaner, safer, and more efficient cleaning tool.

Took me about two hours from unpacking to getting it up and running, after all, this is an advanced five-axis CNC machine, which is hard to get started for a novice, requiring sufficient knowledge of CAM controller software. Fortunately, I'm proficient in FANUC and Siemens control systems. If you're new to CNC programming, it may take longer. The instructions included were clear and easy to follow, and all tests went flawlessly. The only downside is that this unit is expensive and out of the budget of most CNC guys. All in all, great value for money in my opinion.

This is my first attempt at CNC mill with a learning curve. It appears to be more rigid than the average CNC router. I love the sturdiness of this unit. I got excellent support from STYLECNC in solving some mechanotechnical faults and particular issues. This unit is the best bang for beginners in metal fabrication with heavy construction and clear assembly instructions. I have a lot to learn but had my first aluminum milling project up and running in no time, and the result is as expected. I will try cutting aluminum sheets in the next days, and I think it will work great as long as I use the right end mills and set the right cutting speed and other parameters in the software.

So far this automatic milling machine is as good as I expected and serves its purpose in my gunsmith shop to repair, design, modify, or build guns. Sturdy enough with its structure for metal fabrication. If you take the time to learn the CNC controller software, the mill table will be easy to use and provide excellent quality works. In addition, there are some upgrade kits to bring it to the next level. I recommend ST7090-2F for the price and quality.

I purchased this CNC mill for mold making with aluminum and copper. Easy to assemble and performed better than promised. Easy to use and worked well after setup. You should not beat the price for what this machine is capable of doing for hobbyists. The software is available for beginners, as well as for professionals. I will recommend this machine to anyone looking to get started in milling jobs at a reasonable price.

The ST6060F arrived safely packaged 18 days after ordering. Since I was already able to gain experience with the CNC mill, the construction went quite quickly. Unfortunately, I found that the control board was not working properly, but on the same day STYLECNC sent me a new board directly from China with DHL Express. After 5 days, the part also arrived undamaged, spending two days at customs. Installed and everything is as I expected. I am very satisfied with the milling machine, it is now running great with NcStudio software to make aluminum molds and parts.

It was fairly easy to assemble, had to see a video for only one area. Hasn't given me any issues really minus the drive screws getting junked up which is normal super simple to clean and put a light oil on and they quiet down an work like a charm.

In conclusion as a first machine to learn on and familiarize yourself with CNC milling, this machine is great. I would recommend it for anyone starting out before wasting a lot of money on something that they may not enjoy doing.

I was able to be fully functional and making projects within 24 hours of receiving this machine!

After my machine was ready, I went to their factory for training. This company was really professional, and their engineers taught me a lot. I'm going to buy some other CNC machines from this company.

It's my first time to buy goods from abroad, but I have to say I got one good experience for the oversea purchase from STYLECNC. In terms of using the five-axis CNC machine, they offer free online training for assembly and operation. Getting started and connecting it to the PC is very easy, and it runs smoothly and cuts are made with precision.

This lathe performs as advertised, boasting a heavy-duty bed frame and a wealth of features. I have been playing with it for a couple of weeks, turning dozens of table legs, and everything has lived up to my expectations - The STL1530A-7T operates flawlessly, and the milling spindle is impressive, allowing for personalized carvings on turnings. Furthermore, the CNC controller automates every capability, making it easy to balance quality and speed. This automatic feeder enables mass production and is a great partner for those committed to industrial mass manufacturing. So far, I'm 100% satisfied.

I went straight for a CNC lathe, despite having no previous manual turning experience. As a newbie, I was a little nervous at first, but the user-friendly controller made everything very easy to operate, without a hard learning curve, aside from the CAD software. However, this didn't bother me at all, as I already got all the vector files - my brother had created all the drawings for my business. All in all, it met my expectations and didn't let me down. I'm very satisfied with my choice.

Bought this lathe for my high-end candlestick customization business. Received in 25 days, ready to use out of the box, no assembly required. Comes with all the parts and tools needed for turning. As an experienced carpenter I couldn't wait to play with it. After a month of use, I've turned a lot of items with this wood lathe, performing well without any trouble. With CNC, variable speed is no longer an issue. Everything goes smoothly, allowing you to enjoy the fun of woodturning easily without the need for hands. It's a pity that I didn't buy more blades as consumables with the machine (which would save me shipping costs), after all, tool wear is a big problem, and it's much cheaper to buy turning tools directly from Chinese manufacturers than from Amazon. If the extra budget is available, an additional dust collector is a must-have for cleaning up the excess wood chips. All in all, this is a great starter for wood turners who want to give automatic lathing a go. I would give the STL0525 a five-star rating and recommend it to all my fellow woodworkers.

Hard to make up my mind when I ordered this lathe for woodworking at STYLECNC. After all, I had been working with manual lathes for the past few years, and was a little apprehensive about getting started with CNC. My hanging heart relaxed at the moment of unpacking.

PROs:

• Basically all in one, no trouble with assembly.

• Well made with heavy-duty bed structure.

• Full-sized to handle most woodturning projects.

• Easy to get started and fun to play, with instructional documents and videos.

CONs:

• Creating CAD files is hard for CNC beginners like me.

• Controller software compatibility is limited, no other options except what comes with it.

Conclusion

More features remain to be tested in the future time. Overall, so far so good and great value for money.

This lathe came 100% assembled from STYLECNC, plug and play, and the first thing I did was just rough in a table leg for fun. The CNC controller made it super easy to play with, and the woodturning was smooth and clean, far exceeding my expectations.

Pros: Heavy-duty cast iron bed makes it sturdy and durable. Fully automated CNC control system frees your hands, improves productivity and saves manufacturing costs.

Cons: Must go with the auto-feeder option (about $1,000) if you try to take off too much wood blanks at once, as well as a software upgrade.

All in all, It's a beginner-friendly lathe machine for getting started with woodworking automation. Best lathe ever and so far STYLECNC hasn't let me down.

Well built lathe, all parts are well made and solid. The controller software is easy to learn and use for those new to CNC programming, creating smooth and clean bats in minutes. Great value for money. It's a pity that I didn't order the automatic feeder, which would increase the labor cost and waste time. Looking forward to future upgraded versions.

Bigger than I could imagine, but the lathe itself is well built, solid and durable. As an upgraded version of my manual lathe, the STL2530-S4 can handle both turning and milling. Everything is automatic with CNC controller, apart from changing of turning tools and loading of wood blanks. My stair balusters and table legs can be decorated with beautiful patterns or reliefs milled by the built-in spindle, which are pleasing to the eye and no longer boring. Can't wait to move on to more woodworking projects.

Great value for money, cheap but well built. Easy set up with instructions. Everything works as described, powerful and smoothly. Continuously variable speed is perfect for finishing. CNC software is user-friendly for carpentry in wood turning. All in all, an affordable beginner lathe for all.

I'm new to turning on a CNC lathe. Looking for an entry level automatic wood lathe for bowls. Did a lot of research and decided to give the STL0525 a try and it lived up to the hype and exceeded my expectations. Well built and sturdy. I have made several wooden vases and bowls. Fast speed with high quality. I can't express in words how much I enjoyed this process. This is a great value for the money. I'm very satisfied. Glad I made the purchase. What I have to say is that STYLECNC's customer service is professional and outstanding, especially for a novice like me, getting started in just one day without a steep learning curve.

I wanted to get into turning posts and stiles. I have never used a wood lathe at all. This unit is just perfect. All the parts are tight and balanced. It performs well and produces smooth work. It has been great for the price and my needs. With the CNC controller and the instructions came with the machine, I am able to use it with no any experience. I love it and am having so much fun. Overall, I would recommend this product to all.

I bought this lathe for my son as a Christmas gift with a great price. It performs good quality and easy to use. All the parts are tight and balanced. He is a beginner at this automatic lathe with CNC controller. With the instruction manual and YouTube video tutorials from STYLECNC, he is able to use it with no experience at all. It produces good smooth work in almost all types of woodturning cuts. He loves it and is having so much fun.

I am a beginning turner and have to purchase a mini lathe to start with. This one is quite easy for me to learn. It is automatic and requires no human intervention. It is very solid and runs smooth and quiet. I have been using this lathe almost exclusively for hardwood turning since I got it, which is fantastic as advertised. It works great so far for turning pens and some small beads, vases and bowls in my woodworking shop.

This CNC lathe arrived in perfect condition. A well made machine with great quality control. All the parts are well built, tight and balanced. The bed frame is heavy duty with cast iron structure, which make it more stable to work. I have made some wood balusters and stair spindles. The variable speed works very well, and the automatic speed control system is easy to use, and no human intervention required. The results are fine and clean. Worth every penny. Great lathe machine for woodworking.

This is my first experience with a lathe like this, it is easy to use for me, the Automotion with CNC is the best feature, and the power is good for woodworking. I have made hundreds of stairs spindles and wood balusters with carbide turning tools, and everything runs well. Great value for the money, I hope it continues to work optimally.

I have owned this lathe machine for a few months, and it works really well. I upgraded from a smaller one. Turned some small woodworking projects of bowls and vases, and now working on table legs that will take advantage of the larger swing. This is a great automated lathe for woodworking and worth the money. It has a CNC controller for automatically turning without a manual. All in all an excellent CNC lathe for beginners.

Got it, delivered pretty fast. Everything seems fine. I have finally been able to try out the machine and it is working quite well. I am excited to get this CNC lathe, and pleased with its performance. I will recommend the product and technical support from STYLECNC.

I've used quite a few manual plasma cutters in the past, but this was the first time playing with a CNC so was a little overwhelmed. One of the metalworking forums I belong to had many recommendations for STYLECNC. Did a little research and decided to go with the STP1530R at less than 1/2 the cost of the fiber laser cutter with similar capabilities, capable of cutting both sheet metal and tubing (while plasma cutting is not as precise as laser cutting, it is more than adequate for my business). Arrived in 20 days, initial impression is good, the heavy-duty 5x10 full-size plasma table is sturdy enough, the rotary attachment accommodates a wide range of tubing, and the CNC controller looks very user-friendly. So far, I think it's a good buy, 100% worth the price. I will update the review with further use.

This plasma cutter is a standout cutting tool and exceeded my expectations. It works great for my metal cutting projects with stainless steel and aluminum. I praise its fast cutting speed and ease of use, thanks to its intuitive interface and advanced CNC controller, providing a smooth cutting experience. Note that it runs on a 380V power supply, which is something to consider for those that don't have this voltage.

The 5x10 plasma table with Hypertherm Powermax 125 arrived on site in good condition. We were able to set up the machine with minimum experience. Just ensuring the flatness and square the machine. It arrived with in-house software installed and fortunately no startup bug. A good value machine.

Purchased on January 5th. Received yesterday. Packaged well without any damage. Hooked it up with a 220v adapter. Today was the first time I actually used this kit for cutting 1/8 steel diamond plate, and it cut out as well as I expected but way faster. I'll try this CNC plasma table with thicker and thinner metals soon and see how it goes. Overall, it's a quality metal cutter.

I purchased this plasma cutter after watching a YouTube video review. Packaged very neatly and everything arrived intact. I have used it to cut 1/4 flat bar with it, worked well and performed as advertised. Everything is automatic with CNC controller, which cut right through like butter with high speed. This unit would be a great machine for a professional or a good cutting tool for the occasional user or home hobbyist.

Quality parts and easy to assemble & use. Works well with 220 volts, have used this sheet metal & tube plasma cutter a handful of times, cuts sheet metal from ⅛-½ smooth as butter. I'll try tube cutting in the next days. So far I am ecstatic about my purchase.

This CNC was purchased for my business expansion. Quality parts and easy to put together. I was curious how well it could cut. The torch automatically moved along the tool path to cut through sheet metal, resulted smooth contour cuts with a guide of CNC controller. Great cutting tool for commercial use.

This CNC plasma cuts very easy on 220v, like cutting butter with a hot knife. Very good machine, but I also recommend purchasing the nozzles and the tips of the torch (consumables) they wear out quickly and for a good operation they must be in good condition.

Cuts 1/4 plate effortlessly. Easy to learn to use. Nothing fancy and have no issues. Highly recommend for the home hobbyists. Cuts are accurate and clean enough to cut with little preparation. Very good machine and excellent customer service.

If you are wavering on this purchase like I did. Buy it.

It worked pretty good, cuts 3/8 steel without a problem. Only time will tell if it will stand the test of time. I have had this for a while now granted I don't use it every day, but machine is still working great. I don't regret buying it.

I was hesitant to buy this plasma table due to its price and abilities, but finally I decided to give it a try. It's so easy to use with CNC automation. I wanted to cut everything in my repair shop, and tried to cut through a few steel plates, as well as round tubing and square tubing. All worked smoothly with fast speed. Great cutter for what I paid for.

Precision cutting tool for fabrics. Easy to use and essential in your clothing store. From feeding to cutting, everything is automatic. I tried cutting digital printed fabric and got precise cuts without the burnt edges that laser cutting tends to do. So far, this CNC cutter is perfect. Easy to get blades and tools for it too, which was a consideration. All in all, a game changer for my custom apparel business, and no more scissors.

I purchased the STO1625A two months ago and to my surprise it showed up at my door less than 30 days after I placed the order. It took me about 2 hours from start to finish, but once it was done, I felt a great sense of accomplishment. I had a few software issues with the first boot, but I called Mike and he was able to help me out quickly. I have been using this oscillating knife to cut fiberglass and fabric and I am very happy with the results I get. I've never used an automatic CNC cutter like this before, but now it keeps my creative juices flowing.

I purchased this automatic CNC cutter to make corrugated cardboard boxes for my custom packaging business. This machine is well designed to cut flat materials quickly with little effort. It is easy to setup and use, and cuts through cardboard like butter. In addition, the blade is replaceable to cut different materials. Overall, an excellent digital cutting tool for flexible materials. I recommend it for fine cuts where exact precision is needed.

This automatic digital cutter has completely changed my way of thinking in cutting fabric. I have always used different sizes of scissors for this job in the past, However, I used this automated fabric cutting machine on cotton fleece fabric in my clothing customization workshop, and it was like a hot knife through butter. It was precision with the clean edges. In addition, it is stable and easy to use and it has an impressive automatic controller. I think for the price you do get a quality machine which will save you cost and time.

Great automatic gasket cutter with CNC controller for commercial use. It is easy to cut square, rectangular, circular, and special shape gaskets & seals with outer and inner diameters in one pass. I have made some gaskets with 1/8 inch thick rubber, and got clean accurate cuts with high speed, which can meet the original standards in industrial manufacturing. I will try to make some cork gaskets in the next days.

I received the CNC knife cutting table on time and in good condition. It took me 3 days to get the hang of it and learn how to use this tool properly. So far just doing lots of leather jacket cutting projects. No noise and dust at all. A great automatic leather cutter to work with.

I bought this automatic CNC knife cutter to make gasket with rubber and asbestos. Easy to operate, and almost no learning curve needed for assemble, software installation and setting. Have used it for a few months. Everything has been running well with clean accurate cuts. I rate this gasket cutting machine as 5 stars for quality and value.

I use this digital cutting machine to cut fashion and textiles. Cuts perfectly well with smooth edge. I like how easy it is to use this fabric cutter. Great value for the price.

This gasket cutter takes some getting used to, but offers clean cuts. It works better than I was expecting. It is easy to cut through standard flange gaskets of 1/16 and 1/8 inch without issue, and every operation is automatic. In addition, the overall build is very sturdy to ensure precise cuts. Brilliant cutting tool. Recommend it to all.

나는 당신에게 말할 수 없습니다. 그러나 내경과 외경이 있는 원형 개스킷을 한 번에 절단해야 하는 경우 이것이 바로 그것입니다. 나는 2-21/32 OD 및 2-5/16 ID인 1/16인치 두께의 고무 개스킷 링을 자릅니다. 깨끗한 컷으로 모든 것이 좋습니다. 훌륭한 자동 개스킷 절단기를 만들어준 STYLECNC에 감사드립니다.

A great automatic gasket cutting machine with pneumatic oscillating knife, I have made a test for gasket cuts, reasonably solid & accurate, no burnt edge. The CNC controller made everything run smoothly. I would attempt gaskets that requires actual precision in the next week.

I've never used an automatic machine like this before only handheld edge bander. The edge banding machine went together with software installation and debugging in about 2 hours. I was happy with how easy it was to assemble the kit and get started. It took about 5 minutes to make one board. Take a look at it under magnification, the banding matches the reveal side the plywood perfectly and does not show seams.

The automated edge bander machine is great and works as expected. As long as you stick to the recommended settings you will make some cool pieces. The ends are flush with the top and side pieces, and the trimmer will cut away any excess fringe strips.

I got the ST-280 before the scheduled date. It is an awesome edgebander for cabinet making. I have edgebanded the kitchen cabinet doors with 500 lineal feet of 1mm PVC so far and it really worked and looked great for all my plans. The whole process is done automatically without manual intervention. I will try the thinner edgebanding in the next week.

Let me say that I stopped working just to leave this review. I've done a lot of research on this automated edgebander for 3 months and I'm hesitant to buy it. But I'm glad I did it, and it worked fine. I have edgebanded over 200 feet of 3/4 birch plywood with melamine edgebanding so far and am very happy with the results.