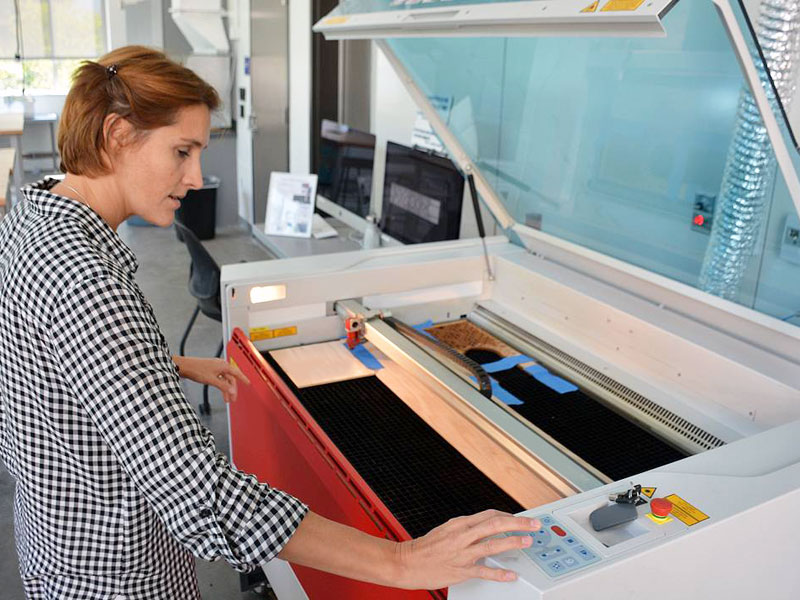

The laser cutter is already a tool for general mechanical cutting. I think that many users are not using the laser cutting machine after knowing its operation steps, and some may only use it in accordance with the habits. This will inevitably have some negative effects on the use of laser cutting machines. Here, we should remind you that if you want to be able to use the laser cutter machine safely, you must be familiar with its structure and its use steps. Let's briefly talk about 26 basic steps:

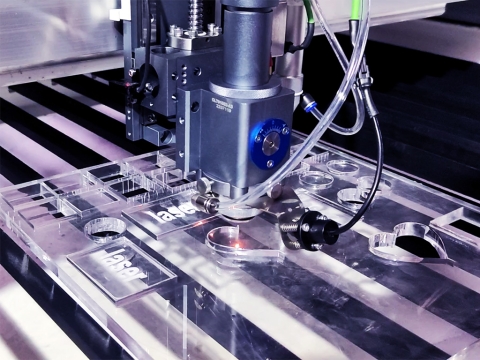

STEP 1. Prepare the material to be cut and fix it on the workbench.

STEP 2. According to the material and thickness, call the corresponding parameters.

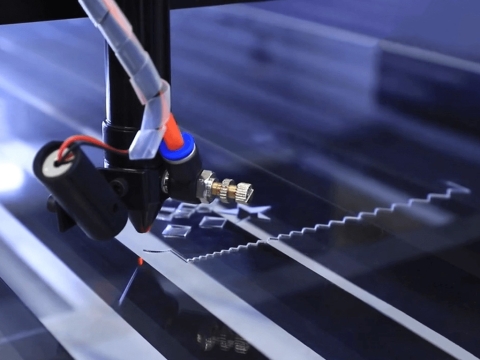

STEP 3. Select the corresponding lens and nozzle according to the cutting parameters, and check whether they are intact.

STEP 4. Adjust the cutting head to the proper focus.

STEP 5. Check and adjust the nozzle center.

STEP 6. Calibration of the cutting head sensor.

STEP 7. Check the cutting gas, enter the command to turn on the auxiliary gas, and observe whether it can be ejected from the nozzle well.

STEP 8. Test the material, check the profile and adjust the process parameters until the production requirements are met.

STEP 9. Prepare the cutting program according to the drawings required by the workpiece and import it into the CNC.

STEP 10. Move the cutting head to the starting point to be cut, and press "Start" to execute the cutting procedure.

STEP 11. The operator must not leave the machine during the cutting process. If an emergency occurs, press quickly: "Reset" or: "Emergency Stop" to terminate the operation.

STEP 12. When cutting out the first workpiece, pause cutting to see if it meets the requirements.

STEP 13. Check the auxiliary gas flow rate when cutting. If the gas is insufficient, replace it in time.

STEP 14. The operator must undergo training, be familiar with the structure and performance of the equipment, and master the knowledge about the operating system.

STEP 15. Before clarifying whether a material can be irradiated with laser or heated, do not process it to avoid the potential danger of smoke and vapor.

STEP 16. Wear labor protective equipment as required, and wear protective eyewear that meets the requirements near the laser beam.

STEP 17. Keep the fire extinguisher within easy reach, turn off the laser or shutter when not processing, and do not place paper, cloth or other flammable materials near the unprotected laser beam.

STEP 18. Observe the general safety operation rules of the cutting machine. Start the laser strictly in accordance with the laser startup procedure.

STEP 19. Keep the laser, the bed and the surrounding area tidy, orderly, and free of oil stains. Workpieces, plates, and waste materials are stacked as required.

STEP 20. When the equipment is turned on, the operator should not leave the post or leave the person to take care of it without permission. If it is really necessary to leave, stop or turn off the power switch.

STEP 21. When an abnormality is found during the processing, it should be stopped immediately, and the fault should be eliminated or reported to the supervisor in time.

STEP 22. Observe the high voltage safety regulations during maintenance. Every 40 hours of operation or weekly maintenance, every 1000 hours of operation or every six months of maintenance, follow the regulations and procedures.

STEP 23. When using gas cylinders, avoid crushing the welding wires to avoid leakage accidents. The use and transportation of gas cylinders should follow the gas cylinder supervision regulations. It is forbidden to expose the gas cylinder to sunlight or heat source. When opening the bottle valve, the operator must stand on the side of the bottle mouth.

STEP 24. When working, pay attention to observe the operation of the machine tool, so as to avoid the cutting machine out of the effective travel range or collision caused by the collision of the two.

STEP 25. After inputting the new workpiece program, it should be trial run and check its running status.

STEP 26. After turning on the machine, you should manually start the machine at low speed in X and Y directions, and check to see if there are any abnormalities.

The above is almost the operation to complete the entire cutting process. Although they are all very basic things, the problem is often in such a trivial detail. We hope that everyone will carefully check every aspect of the work in the future operation process to achieve safe production.