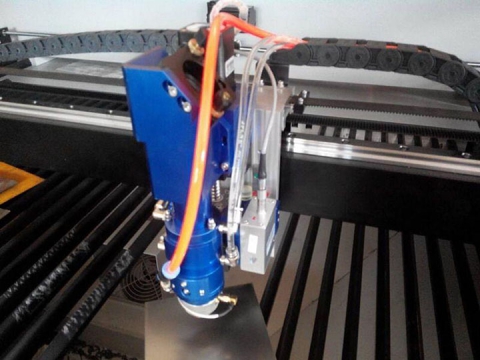

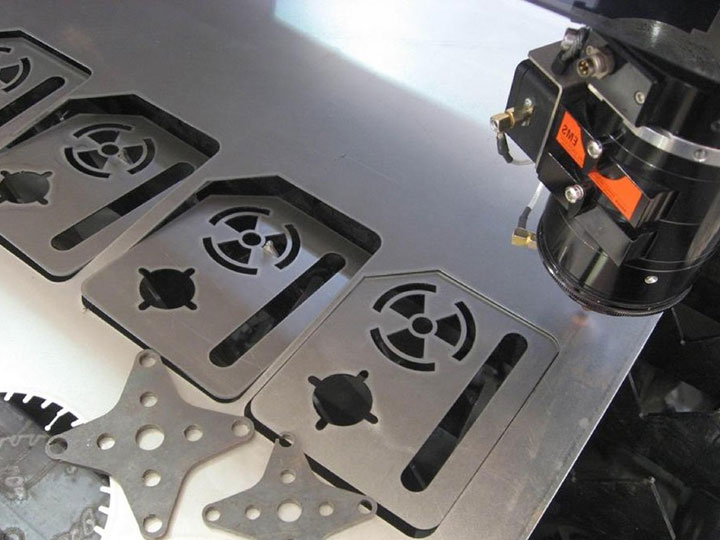

Laser metal cutting machine manufacturers of the relevant parts of the final cutting quality also has a certain impact. This is because many of the core parts of the metal laser cutting machine is good and bad, and the different quality of the core configuration directly affects the system performance of the metal laser cutting machine. The system performance of the laser metal cutting machine is related to the configuration of a lot of correlation, and the quality of the laser metal cutting machine directly affects the cutting effect. Usually on the market, many small laser cutting machine manufacturers in order to save costs, the configuration of the low-end parts, which will reduce the price, to take advantage of the price among the laser industry and big brands such as the Han laser competition. So produced by the end of the laser machine is just a time bomb, with the market choice, will eventually be eliminated. So users in the pre selection process must polish eyes, don't buy inferior products, do not buy defective products, don't because of some low price differences affect cutting quality, finally, it is worth the candle. Import quality parts in general can ensure that the optical fiber laser cutting machine has a high quality of the cutting effect. STYLECNC® laser metal cutting machine has been all parts with a world-class high-end brands, including IPG, coherent, Leshi, Yaskawa, PMAC, LASERMECH, PRECITEC, American IV, FESTO high-end brand products.