Laser lens is divided into many types of focusing lens, lens protection and so on, in the course of their work no can avoid will be subject to some of the pollution, such as water pollution and dust pollution, then daily maintenance process requires of laser lens cleaning guarantee the laser cutter stability. Cleaning lenses, of course, do not want to be in our lives, like a clear lens, we need to pay special attention to this paper on laser cutting machine in the correct method of cleaning the laser lens.

The process of cleaning the lens, the only purpose is to remove the contaminants of the lens, and do not cause further pollution and damage to the lens. In order to achieve this goal, people tend to adopt a relatively small risk approach.

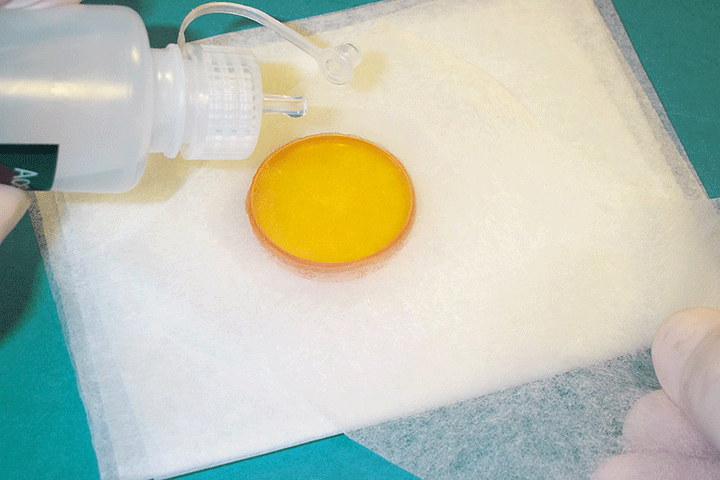

First application of spherical air blow off floating on the surface of the component, especially on the surface of the lens of the tiny particles and colloidal floc, this step is necessary. But do not use the production line of compressed air, because these will contain oil and water droplets in the air, which will deepen the pollution of the lens.

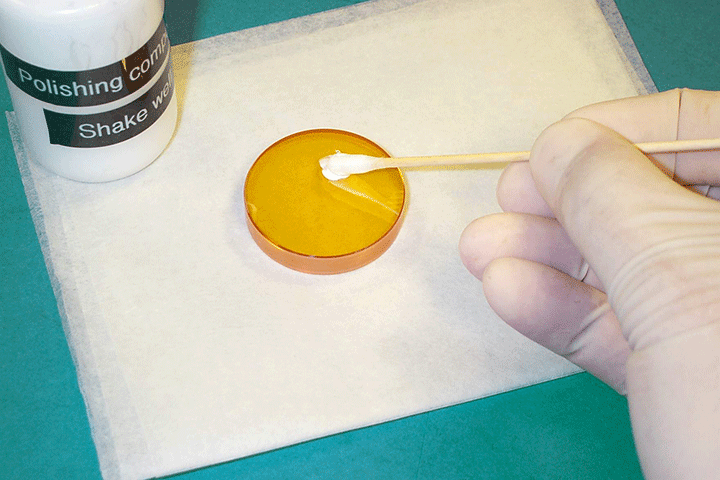

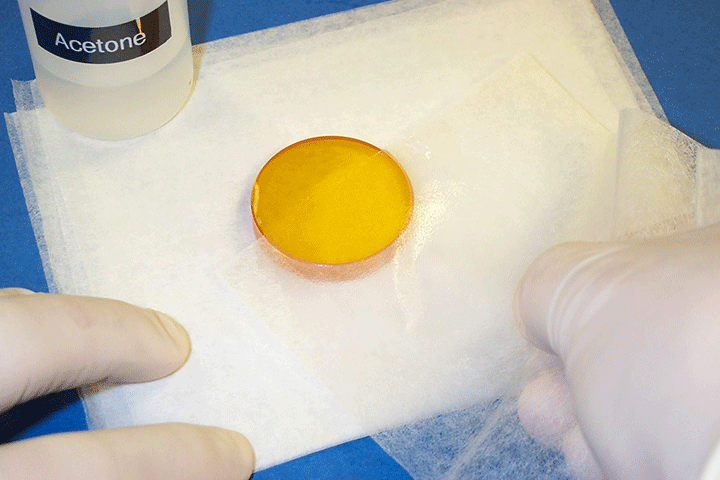

Second step application of acetone on the lens for minor cleaning. This level of acetone is almost anhydrous, which reduces the possibility of lens contamination. The cotton ball dipped in acetone must be cleaned in the light of the lens, and do ring movement. Once dirty, the cotton swab must be replaced. Cleaning should be done in order to avoid producing wave bars at a time. (if the lens has two coated surfaces, such as a lens, each face needs to be cleaned with this method. The first need to be placed on a clean sheet of paper to protect it. )

If the acetone can not remove all the dirt, then wash with acid vinegar. Acid vinegar cleaning is the use of the dissolution of the dirt to achieve the removal of dirt, but will not cause damage to the optical lens. This is the level of vinegar can (diluted to 50%, or 6% strength) household vinegar or acetic acid. Cleaning procedures and washed with acetone and then by acetone to and fro in vinegar and wipe the lens, then to frequent change cotton to completely absorb acid and hydrate.

Note: can only use the check - in - stick cotton swab. Only through the use of high quality medical cotton picking, does not contain any abrasive.

Of course, some pollutants and lens injury can not by washing to remove, especially film burn caused by metal spatter and dirt, to restore the good performance, the only way is to replace the lenses. The correct installation method in the installation process, if the method is not correct, it will make the lens is contaminated. Therefore, the operating procedures should be followed. If a large number of lenses need to be installed and removed, it is necessary to design a fixture to complete the task. The specific fixture can reduce the number of contact lenses, thereby reducing the risk of lens contamination or damage.

In addition, if the lens is not installed correctly, the laser system will not work properly, or even will be damaged. All carbon dioxide laser lenses should be installed in a certain direction. So the user should be sure that the correct direction of the lens.

Mirror is the third common lens, its installation is also very critical. Of course, it is easy to identify the reflector. Obviously, the coated side facing the laser. In general, manufacturers make a mark on the edge to help identify the surface. In general this notation is the arrow, the arrow to the side. Each lens manufacturer has a system that is marked by a lens. Generally speaking, the arrow is opposite to the mirror and the output mirror. For the lens, concave or flat in front of the arrow. Sometimes, the label of the lens will remind the meaning of the mark.

When the lens is properly cleaned and operated, its service life and performance will undoubtedly improve, which is also one of the important ways to improve the life and stability of laser cutter machine. Take some preventive and maintenance measures will be able to ensure that the laser cutting machine work longer, more stable.