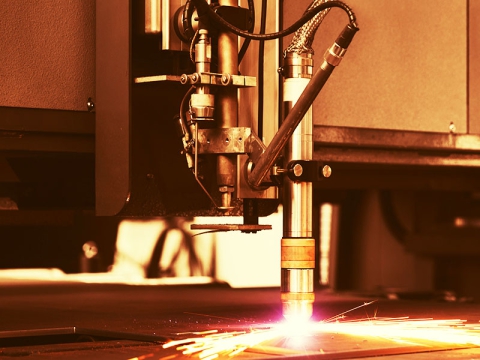

A plasma cutter is a versatile tool used in various industries for cutting metal quickly and accurately. The cost of a plasma cutter can vary significantly depending on several factors such as brand, quality, power output, additional features, and intended use.

Generally, prices can range from a few hundred dollars for smaller, entry-level models to several thousand dollars for industrial-grade machines. High-end plasma cutters used in professional or industrial settings can cost $10,000 or more. It is essential to research different models and their specifications to find one that suits your needs and budget.

In this discussion, we will explore the different aspects influencing the price of plasma cutters and provide insight into what you can expect at various price points.

Entry-Level Plasma Cutters

Heard of entry-level plasma cutters? These plasma cutters are typically designed for hobbyists, DIY enthusiasts, or small-scale metalworking projects. These machines often have lower power outputs and cutting capacities compared to industrial-grade models.

Prices for entry-level plasma cutters typically range from around $200 to $1,000. At the lower end of this spectrum, you will find basic models with limited features and lower cutting speeds. As you move up in price, you may encounter models with improved performance, better build quality, and additional accessories.

Mid-Range Plasma Cutters

Mid-range plasma cutters offer a balance between affordability and performance. These machines are suitable for small to medium-sized fabrication shops, automotive repair shops, and contractors who require more cutting power and versatility.

The prices can vary but typically, prices for mid-range plasma cutters are from $1,000 to $5,000. In this price range, you can expect to find models with higher cutting capacities, faster cutting speeds, and more advanced features such as CNC compatibility, improved duty cycles, and enhanced consumable life.

High-End Plasma Cutters

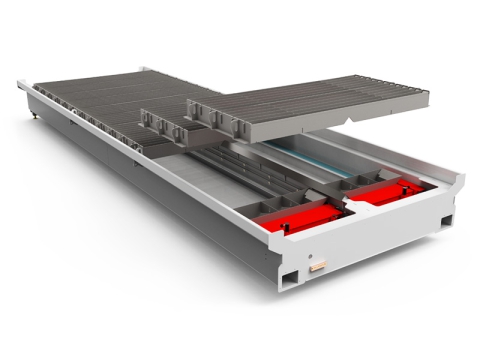

High-end plasma cutters are designed for professional and industrial applications where precision, reliability, and cutting speed are an essential factor.

These machines are capable of cutting through thick metal plates with ease and are suitable for heavy-duty fabrication, construction, shipbuilding, and other demanding tasks. Prices for high-end plasma cutters can range from $5,000 to $20,000 or more, depending on the brand, model, and specifications.

In this price range, you will find top-of-the-line machines with advanced cutting technologies, high power outputs, superior build quality, and extensive warranty coverage.

Factors Influencing Cost

Several factors that influence the cost of a plasma cutter:

Power Output

Plasma cutters are available in a range of power outputs, typically measured in amps. Higher amp models can cut through thicker materials and generally cost more than lower amp models.

Cutting Capacity

The maximum thickness of metal that a plasma cutter can effectively cut will impact its price. Machines with larger cutting capacities command higher prices due to their increased capabilities.

Brand and Quality

Well-known brands with reputations for reliability and performance often come with higher price tags. Quality construction, durable components, and advanced features contribute to higher costs.

Additional Features

Plasma cutters may come with various features such as pilot arc technology, CNC compatibility, dual voltage capabilities, and advanced cooling systems. These features can add to the overall cost of the machine.

Consumables and Maintenance

Consider the ongoing costs associated with consumables such as electrodes, nozzles, and swirl rings, as well as maintenance requirements when evaluating the overall cost of ownership.

In short, the cost of a plasma cutter varies widely depending on several key factors. Entry-level plasma cutters may offer affordability and basic functionality, which are suitable for hobbyists and DIY enthusiasts.

However, if you are looking for something professional for businesses purpose that strike a balance between performance and cost, go for mid-range plasma cutter that caters to small to medium-size fabrication shops and contractors. Meanwhile, at the high end, industrial-grade plasma cutters deliver unparalleled cutting power, precision, and durability.

Regardless of the price point, it is important to consider factors such as build quality, reliability, and long-term operating costs when selecting a plasma cutter. Investing in a quality machine that meets your specific cutting needs and workflow requirements will ultimately result in greater efficiency, productivity, and return on investment over time. Whether for hobbyist projects, small-scale fabrication, or heavy-duty industrial applications, there is a plasma cutter available to suit every budget and application.