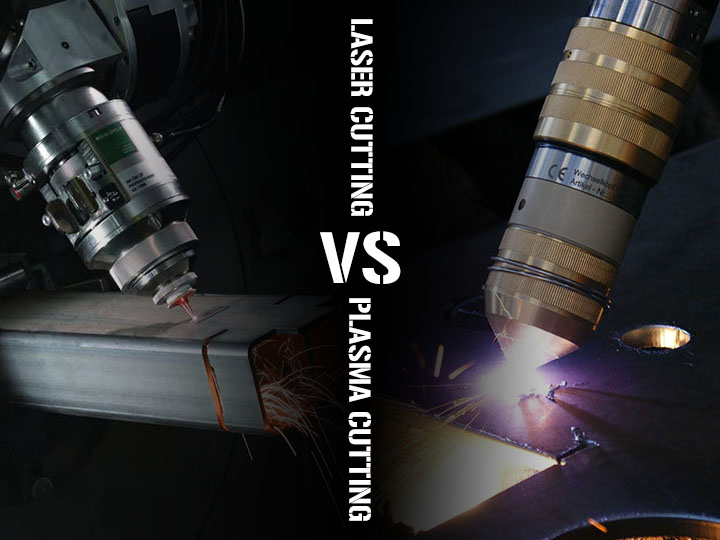

Working Principle Comparison

Ever wondered how does a plasma cutter work? It typically uses oxygen or nitrogen as the working gas, also uses the high-temperature heat of the plasma arc to locally melt and evaporate the metal at the incision of the workpiece, uses the high-speed momentum of the plasma as well to exclude the molten metal to form a groove.

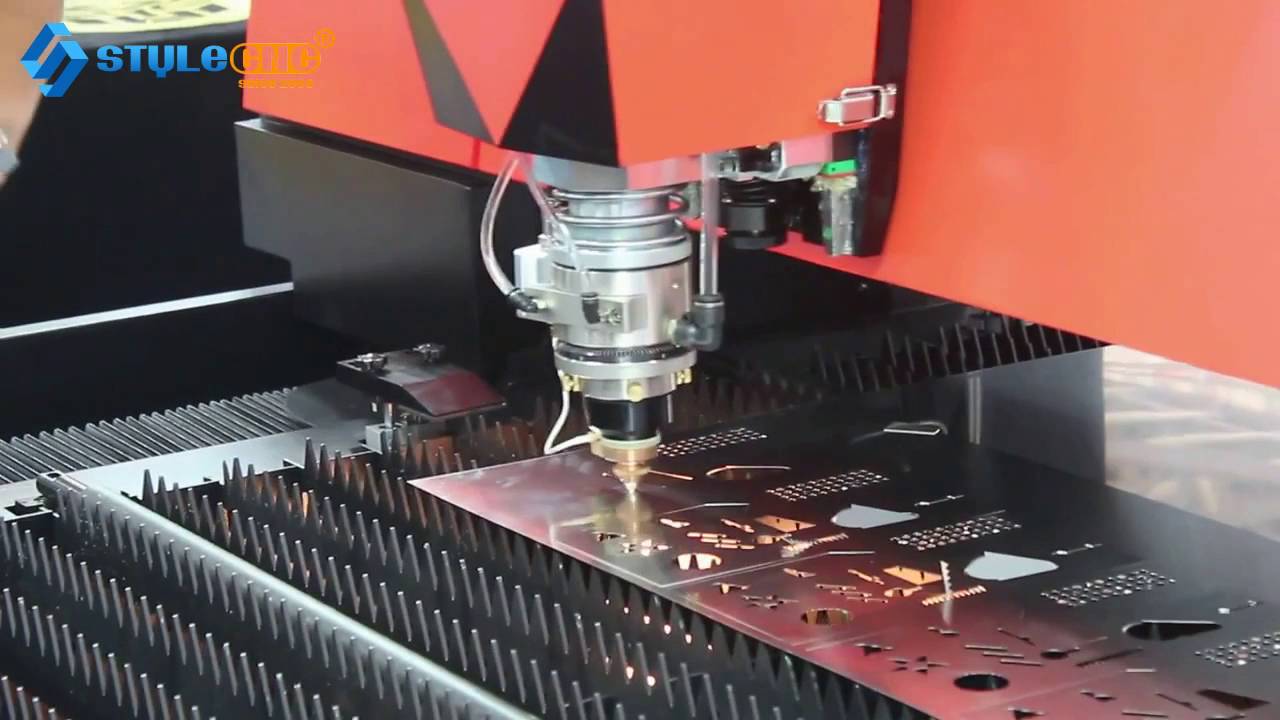

Now, how does a laser cutter work? It uses the laser beam generated by the laser to be transmitted through a series of mirrors, and finally irradiated on the surface of the workpiece by the focusing lens, and then a local high temperature is generated at the focal point, so that the workpiece is heated and melted or vaporized instantly, also use the auxiliary gas to blow away the slag in the slit to achieve the purpose of cutting.

Applications Comparison

Laser cutting machine has a wide range of applications, whether metal or non-metal, it can cut non-metal items, such as wood, fabric, leather, also foam and paper can be cut with CO2 laser cutting machine, and metal can be cut with fiber laser cutting machine. The deformation of the plate is small. Plasma cutting machine can be used for cutting various metal materials such as stainless steel, aluminum, copper, cast iron, carbon steel, brass, gold and silver. Plasma cutting has obvious thermal effect, low precision, and the cutting surface is not easy to carry out secondary processing.

Cutting Thickness Comparison

The industrial application of laser cutting carbon steel is generally below 20mm. The cutting capacity is generally below 40mm. The industrial application of stainless steel is generally below 16mm, and the cutting capacity is generally below 25mm. And as the thickness of the workpiece increases, the cutting speed decreases significantly. The thickness of plasma cutting metal is 0-120mm, and the plasma system with the best cutting quality range of thickness around 20mm is the most cost-effective.

Cutting Accuracy Comparison

The laser cutting slit is narrow, the two sides of the slit are parallel and vertical to the surface, and the dimensional accuracy of the cut parts can reach ±0.2mm. Plasma can reach within 1mm.

Cutting Speed Comparison

Using a laser with a power of 1000W to cut a 2mm thick low-carbon steel plate, the cutting speed can reach 600cm/min. Cutting 5mm thick polypropylene resin board, the cutting speed can reach 1200cm/min. Plasma cutting has slow cutting speed and relatively low precision, and is more suitable for cutting thick plates, but the end face has a slope.

Slit Width Comparison

Compared with plasma cutting, laser cutting is more precise. The slit is small as well, it is about 0.5mm. Plasma cutting slit is larger than laser cutting, and it is about 1-2mm.

Cutting Quality Comparison

The workpiece roughness of laser cutting is better than that of plasma cutting. The thinner the material, the more obvious it is.

Investment Cost Comparison

Different models of laser cutting machines have different prices. Cheap ones such as CO2 laser cutting machines only cost 5,000 US dollars, and expensive ones such as 10000W fiber laser cutting machines now cost 100,000 US dollars. Laser cutting has no consumables, but the investment cost of equipment is the highest among all cutting methods. Although it is not slightly high, also the cost of use and maintenance is relatively high too. Plasma cutters are much cheaper than laser cutters in comparison. Depending on the power and brand of plasma cutters, the prices may vary, also the cost of use is high as well. Ultimately, as long as they can conduct electricity, they are able to cut.

Pros & Cons Comparison

Laser Cutting Machine

Pros

• The laser cutting groove is small: The laser cutting surface can be directly used for welding without grinding.

• Laser cutting speed: The cutting speed of sheet metal can reach 10m/min, which is mostly higher than the plasma cutting speed.

• High cutting quality: Small deformation, low surface roughness value, oblique slices.

• High precision: The precision of the laser cutting machine can reach 0.05mm, and the repeat positioning precision can reach 0.02mm.

• Laser cutting materials: Metal, wood, plastic, rubber, PVC, leather, textiles, plexiglass and other materials, with a wide range of applications.

Cons

The cost of laser cutting is high, and the initial investment and maintenance require high costs too. At present, laser cutting of thin sheets is cost-effective, but when the sheet cutting efficiency is low, unless the quality requirements are higher, it may not be appropriate to use laser cutting then.

Plasma Cutting Machine

Pros

During the cutting process of thick plates, much higher cutting speeds can be achieved, which is higher than laser and flame. It is cheaper than laser equipment, and the maintenance cost is lower than that of laser cutting machine.

Cons

• The verticality of the cutting surface is poor: The verticality is poor and one side of the cutting surface will produce a large bevel.

• During the cutting process, more slag is produced on the surface. Since the process quality is not affected, the slag must be polished after cutting, which also increases labor costs.

• Generation of harmful gas and electric arc: The principle of plasma cutting determines that harmful dust and electric arc will be generated during the cutting process. However, there are methods to avoid the defects of underwater plasma cutting too.

• The tool consumption will be relatively large in the later stage. The cutting nozzle mainly depends on imports, and the cost is relatively high.

Ultimately, the choice between plasma and laser cutting depends on factors such as material thickness, desired precision, budget constraints, and specific application requirements.

Both technologies continue to evolve, offering increasingly advanced capabilities and expanding their range of applications in various industries. Whether it is for large-scale industrial fabrication or precision cutting of intricate designs, plasma and laser cutting remain indispensable tools in the modern metalworking arsenal.

FAQs

Q: What type of materials can laser cutting machine cut?

A: Laser cutting machine can cut materials like wood, fabric, leather, foam and paper.

Q: How much do cheap CO2 Laser cutting machines cost?

A: The cheap CO2 laser cutting machines cost only about 5,000 US dollars.

Q: What effect does plasma cutting machine have?

A: Plasma cutting machine has the thermal effect.

Q: What type of materials can Plasma cutting machine cut?

A: Plasma cutting machine can cut various metal materials such as stainless steel, aluminum, copper, cast iron, carbon steel, brass, gold and silver.