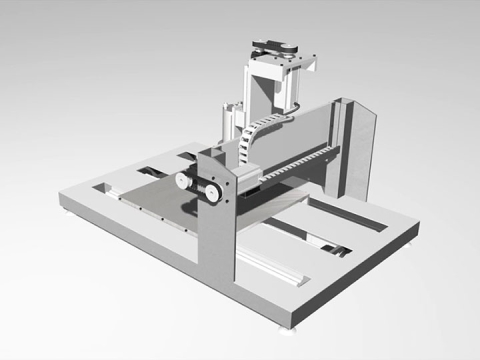

This is a working video for Gunstock 3D Carving by Multi-heads CNC Router Machine with 4 axis rotary and 8 heads from STYLECNC®

Applications of Multi heads CNC Router with 4 axis rotary and 8 heads:

1. Wood Furniture Industry: Wave Plate, fine pattern, antique furniture, wooden door, screen,MDF, craft sash, composite gates, cupboard doors, interior doors, sofa legs, headboards and so on.

2. Advertising industry: advertising identification, sigh making, Acrylic engraving and cutting, crystal word making, blaster molding, and other advertising materials derivatives making.

3. Die industry: A sculpture of copper, aluminum, iron and other metal molds, as well as artificial marble, sand, plastic sheeting, PVC pipe, wooden planks and other non-metallic mold.

4. Relief sculpture and 3D engraving.

5. Cylinders engraving such as wood table legs etc.

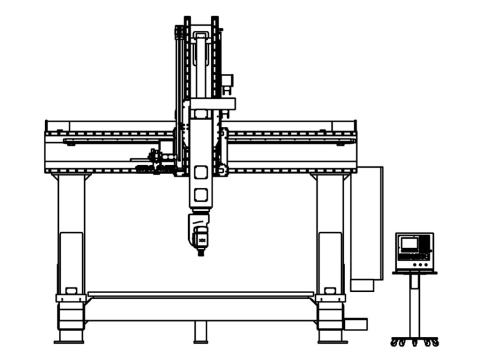

Features of Multi heads CNC Router with 4 axis rotary and 8 heads:

1. It can engrave several materials at one time, which greatly increasing the working efficiency.

2. It can do not only rotary engraving but also flat engraving.

3. Movable working table with high engraving accuracy.

4. Inverter,reducer and spindle are one attached one which make the machine working more stablely and efficiently.

5. XYZ axis use anti-dust system, prevent dust during working, make sure the long lifaspan of square parts.

6. With 8 independent spindles, can enhance the efficiency of engraving work.

7. Each spindle is cotrolled by an independent frequency converter.

8. Can ajust the motor power timely and accurately, it's more power-saving and safe.

9. Suitable for engraving plane and cylindrical materials.

10. With whole casting iron frame, to ensure the structure stability, low inertia and no distortion.

11. HIWIN linear guide and sliding block, Germany made dual screw-nut anti-gap rod.

12. With high accuracy, low noise, and long life.

13. Equipped with high-speed spindle motor, high-performance division drive.

14. Ensure the long time and stable working.

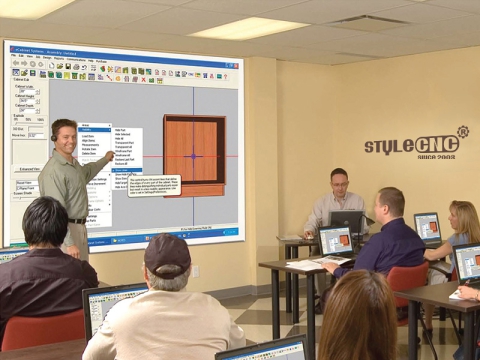

15. Adopted with advanced controlled system, with simple operating software, its easy to learn.

16. And the operator can check the real-time trajectory, plus or minus Z-axis depth in real-time.

17. And adjust the motor speed conveniently.

18. Powerful compatibility for most of software such as: type3, Artcam, Proe, Wentai,CAD / CAM.

19. Humanized design, convenient for removing and installing.

20. Can meet not only the high sensitivity, high accuracy, high speed small sculpture.

21. Can adapt to large acrylic cutting, three-dimensional billboard production, wood carving.