Automotive is a huge industry, encompassing everything from the designing, developing, producing and manufacturing of automotive vehicles, and finishing with the testing, marketing and selling of said vehicles.

There are hundreds of thousands of varying parts, pieces and people involved in the process along each step of the way. With so many different processes involved, it can seem complicated to ensure that it all runs smoothly towards building a safe and roadworthy vehicle.

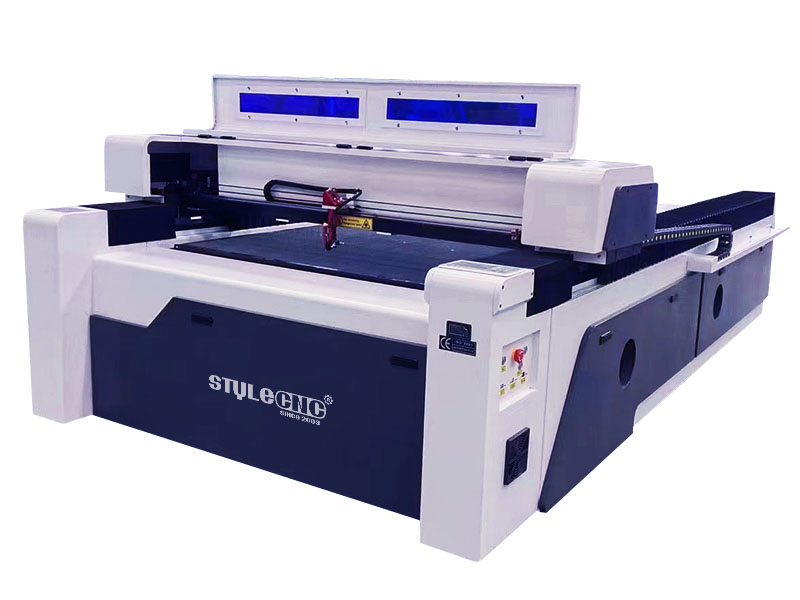

Laser cutting is one process that is used at various stages of automotive manufacture to ensure the end product is reliable and safe for the consumer. In the article below, we have examined this in more details.

Why is a Laser Cutting Machine used in Automotive Industry?

Benefits of Laser Cutting in Automotive Industry

1. Clean and perfect cuts - no edge reworking necessary

2. No material fixation necessary

3. Extremely high level of repeat accuracy

4. Laser cutting and engraving in a single operation

5. No tool wear, therefore consistently high cut quality

6. High degree of flexibility in the choice of contours – without any need for tool construction or changeover

Advantages of Laser Cutting Machine in Automotive Industry

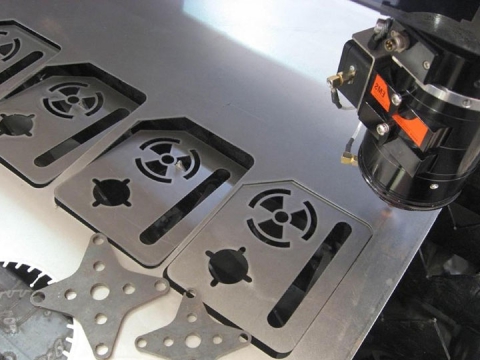

Putting its specific benefits and advantages aside for just one moment, cutting with a laser is one of the most used processes in the automobile industry, and any manufacturing industry for that matter. It involves the process of cutting materials and shapes down to size, and this is something that is widely used when it comes to creating intricate and complicated products.

However, laser cutting itself provides a unique alternative to other forms of traditional cutting that are on the market. Perhaps the biggest advantage is that users can deliver extremely precise finishes with smooth edges, heightening the end product and reducing material waste. Laser-based cutting also uses an extremely low power consumption, it has low maintenance costs, and can be used for multiple applications, reducing time wastage too.

Finally, it is one of the safest processes available. Laser cutting is required to be conducted in an enclosed, tight light box, whereas more traditional and conventional methods see a free-running blade doing the cutting. While steps are taken to ensure that conventional methods are safe, laser cutting simply provides those in the manufacturing industry with one less thing to worry about.

How is a Laser Cutting Machine used in Automotive Industry?

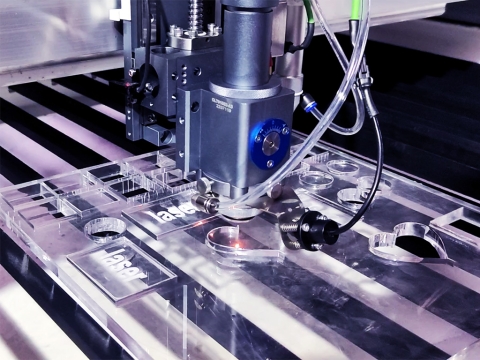

Hardly any other industrial mass produced product has changed everyday life for mankind mote than the motor car. The manufacture of cars and other vehicles is one of the most important branches of industry in many industrial countries. As well as cars, particularly aerospace and shipbuilding are worth mentioning. The laser is being used more frequently in the supplier industry, and frequently replaces conventional processes. Users appreciate the process reliability and consistent high quality of the cuts carried out by the focussed light beam. A seemingly infinite variety of laser-cut components and functional parts can now be found in the fitting and panelling area. Heat-absorbent fibreglass composites, protective coatings, displays, membrane keypads, insulation mats, carbon fibre reinforced composites (CFRP), upholstery fabrics and knitted spacer fabrics in comfortable car seats – all processed nowadays with the laser beam. Now that high-precision laser cutting has been established in the textile processing industry for several years now, the benefits thereof are now becoming apparent, particularly for machining complex functional materials used in the automotive sector.

Automotive Carriage Components

Automobiles today aren’t like the ones designed and produced decades ago. The parts and components now are much smaller and more complicated, such as with apertures for antennas, and laser cutting is the most reliable process for this.

Hydroformed Parts

Hydroformed parts, that is metal parts that have been formed into 3D shapes, are crucial parts for any automobile. Laser cutting is one of the best processes for cutting these shapes smoothly and with absolute accurate precision.

Airbags

One of the biggest benefits of using laser cutting is that it’s not just metal it can cut; it can work with a great number of other materials too. This includes cloth for airbags. Of course, a blade from a conventional process could cut cloth too, but laser cutting has the added advantage of melting the edges extremely quickly, which leaves no fraying.