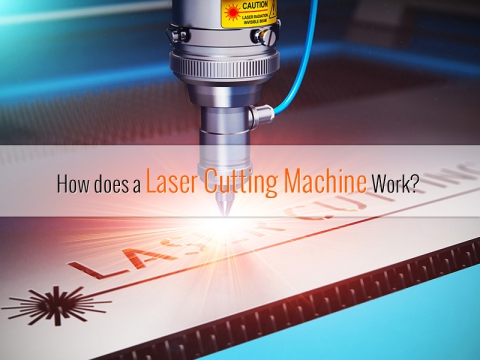

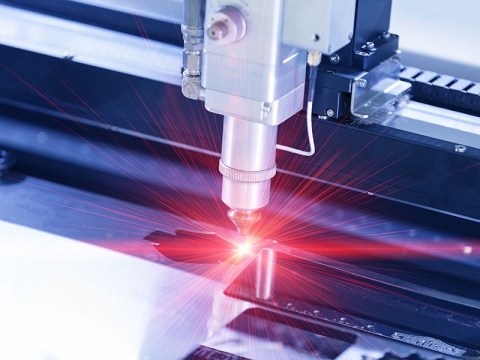

Laser engraving and cutting are realized by applying high power density energy generated after laser focusing. Under the control of the laser system and software, the laser is discharged through pulses, thereby outputting a controlled repetitive high-frequency pulsed laser to form a beam with a certain frequency and a certain pulse width. The pulsed laser beam is guided and reflected by the optical path and focused by the focusing lens group. On the surface of the processed object, a small, high-energy-density light spot is formed. The focal spot is located near the surface to be processed, and the processed material is melted or vaporized at an instant high temperature.

Each high-energy laser pulse instantly sputters a small hole on the surface of the object. Under computer control, the laser processing head and the processed material perform continuous relative movement according to the pre-drawn graphics, so that the object will be processed into the shape you want.

When the laser machine is working, it is very dangerous if it fails. The beginners must be trained by professionals to operate independently. Let's learn the 11 tips to safely operate the laser machine.

1. The laser engraving cutting machine must be connected to an earth ground using a copper wire. It is also recommended to connect the laser engraving and cutting machine frame to the computer frame with a copper wire.

2. The temperature of the cooling water must be from 5°C to 25°C. Check the water temperature often to ensure the temperature does not get hot.

3. Allow the water to circulate for a few minutes so that the metal and glass components can acclimate to the new temperatures.

4. Make sure to carefully follow the installation instruction for the laser tube.

5. While performing alignment, use the control system to move each axis... or remove the motor wires from the amplifiers. Manually moving the axis with the motor wires connected can cause electrical feedback to the amplifier and cause damage to those electrical parts inside.

6. Do not try to cut or engrave before properly aligning the laser beam.

7. Do not place flammable materials into the laser machine. Do not operate the laser if you smell flammable gas in the air.

8. Keep the lens and mirrors clean.

9. Follow a proper maintenance schedule of cleaning and lubrication for the laser machine.

10. The power supply, electrical components, and all wires must remain dry.

11. Turn on the laser engraving cutting machine with emergency stop pressed, test the internal light, then release the emergency stop button to activate entire machine power.