Overview

Edge banding is a specialized manufacturing process used to cover the exposed and raw edges of medium-density fiberboard (MDF), high-density fiberboard (HDF), melamine-faced particleboard (MFC), plywood, particleboard (chipboard), coreboard, and solid wood panels.

An edge banding machine is a dedicated woodworking tool used to efficiently and precisely bond edgebanding to solid and engineered wood panels in custom furniture making and modern woodworking.

Types of Edge Banding

Wood Veneer Edgebanding

Wood veneer is a popular edgebanding material in modern furniture manufacturing. Wood veneer edgebanding involves finger-joining veneer sheets into seamless rolls.

PVC Edgebanding

PVC edgebanding is an excellent option for modular furniture production due to its exceptional strength, ease of repair, and long service life.

ABS Edgebanding

ABS is resistant to water, heat, and detergents for edge banding in bathroom and kitchen furniture.

PP Edgebanding

PP is an environmentally friendly edge banding material - polypropylene, which is the preferred plastic edge banding for furniture manufacturing.

Laser Edgebanding (Zero-Joint Edge Banding)

Lasers heat-dissolve the adhesive layer of the edge banding, fusing it to the panel. This is a zero-joint edge banding technology, making the wood and edge banding appear as a single, integrated surface.

Types of Edge Banding Machines

Manual Edgebanders

• Best for home users and small workshops.

• Manual feeding and trimming is required.

• Affordable but slower than automated options.

Portable Edge Banders

• Compact and easy to move, perfect for on-site work.

• Ideal for countertop installers or carpenters.

Semi-Automatic Edgebanding Machines

• Automatically applies glue and places tape.

• Operator manually feeds panels.

• Faster than manual machines, but still requires some labor.

Fully Automatic Edge Banding Machines

• High precision and high speed for mass production.

• CNC controlled fully automatic edge banding process, from feeding to gluing, from pressing to trimming, as well as finishing.

• Popular in large furniture manufacturers.

What Should I Consider When Buying An Edgebander?

• Manual or portable edge banders are the best option for small business owners or home users.

• Semi-automatic edge banders are the preferred choice for medium-sized furniture makers.

• Fully automatic CNC edge banding machines are ideal for large industrial manufacturers.

• Which material is better for edge banding? ABS, PVC, PP, veneer, polyester, or melamine?

• How thick can the panel be edge-sealed? From 10mm to 60mm.

• Which glue is best for banding? Hot melt adhesive, cold glue, or pre-coated glue?

• Is banding only required or is finishing included? such as scraping, trimming, and polishing?

• How fast is the banding speed? Manual banders work from 1m/min to 5m/min, while automatic banders can go from 12m/min to 36m/min.

• Can the heating system be adjusted to suit different banding types?

• How much does an edge bander cost? Most edgebanders range from a few hundred dollars for manual models to over $10,000 for automatic models. Manual edgebanders typically cost anywhere from $800 to $2,000, while fully automatic CNC edgebanding machines range from $3,000 to $20,000.

Best Edge Banders You Can Purchase In 2025

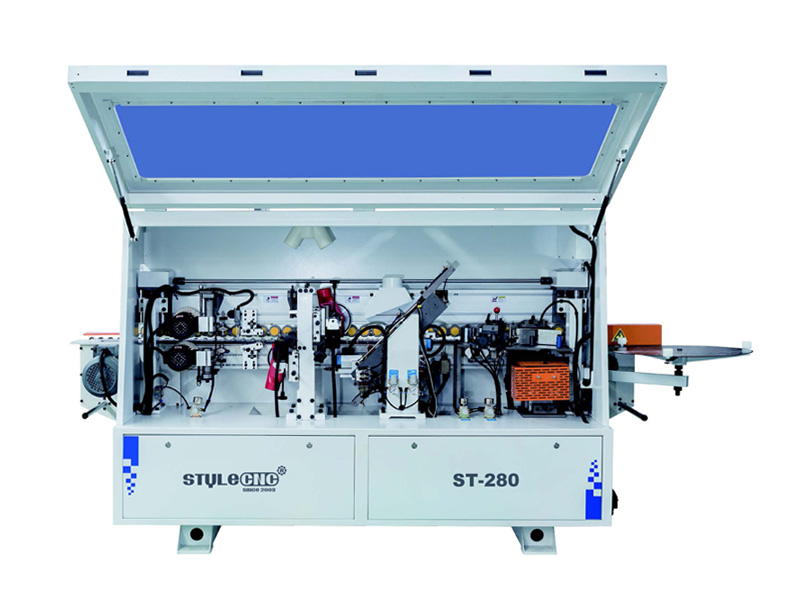

#1 ST-280 (Small-Sized)

Looking for a cheap small wood edge bander to bond, trim, scrap, buff edges for cabinet making? Review the best automatic edge banding machine for woodworking, ranging from $8,000 to $14,500.

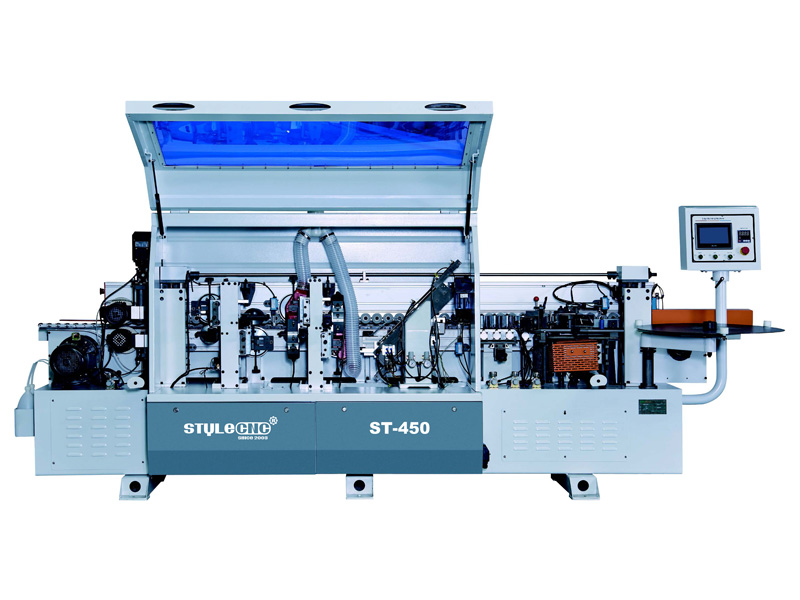

#2 ST-450 (Medium-Sized)

Need custom edge banding solutions to make cabinets, doors and decorations? Review the 2025 best automatic edge bender machine ST-450 for furniture making, ranging from $8,500 - $15,500.

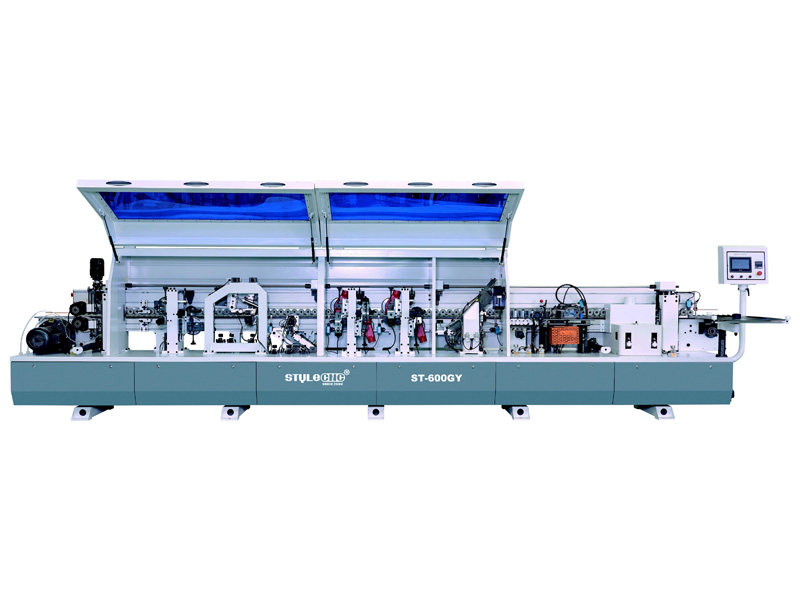

#3 ST-600 (Full-Sized)

Get best deals on automated industrial edge banding machine for MDF, solid wood, block & particle board, polymer doors, plywood, aluminum honeycomb panel, ranging from $9,500 - $17,300.

How to Use an Edge Banding Machine?

Mastering an edge banding machine isn't a one-time process. To progress from edge banding novice to experienced expert, you need to master the operation of an edge bander. Here are 10 easy-to-follow key steps.

Step 1. Check that the machine is working properly and that all components are correctly installed and securely fastened.

Step 2. Prepare the required edge strips and panels, ensuring they are free of dust and oil.

Step 3. Clean and organize the work area to ensure a safe and smooth working environment.

Step 4. Adjust the height of the feed and discharge rollers to match the thickness of the panels.

Step 5. Adjust the position of the pressure roller and cutting blade so that the edge strip adheres tightly to the panel.

Step 6. Place the panel on the machine's feed rollers, aligning the edge of the panel with the feed rollers.

Step 7. Place the edge strip over the edge of the board and gently press it firmly against the board.

Step 8. Push the board into the machine until the edge strip is fully secured.

Step 9. Remove the secured board from the discharge rollers, inspect the edge banding, and perform any necessary trimming.

Step 10. Clean the feed rollers, discharge rollers, and pressure rollers to ensure they are free of excess wood dust or edge banding adhesive.

Conclusion

Edge banding, a crucial process in furniture manufacturing, not only beautifies the cabinet edges but also protects the panel from moisture and damage, enhancing the durability of the furniture. After reading this guide, do you feel you have made the leap from novice to professional?