CNC Machining - What is it?

CNC machining is an automated manufacturing process that creates precise cuts, milling, turning, and engraving. It is much faster, cheaper and more reliable than manual machining. You're about to learn what all this could mean for you and your production needs.

Machining

First, you may benefit from understanding the machining process. Imagine yourself designing something by chipping pieces away from a larger item. Maybe you're carving a wooden log to make a canoe, or sculpting a face out of marble.

Simply put, machining is when you make a desired shape out of something by cutting, shaving or carving away at it. It is a manufacturing term and is commonly thought to involve just metal. In truth, a wide range of materials can undergo machining, including plastic, wood or stone.

CNC Machining

The "CNC" in CNC machining means "Computer Numerical Control". That is because computerized tools are used during the process. Unlike with manual machining, this exposes you to a wide range of advantages.

When machining is done manually, production mistakes are more likely to happen. With CNC machining, you simply set up a computerized tool once. A final product can then be made at a fraction of the speed. You can even repeat the process at the same speed and with the exact same accuracy.

● Higher quality is CNC machining's best assurance.

● You can make more components more efficiently.

● The risk of human error is reduced to a minimum.

● Manual adjustments do not affect the consistency of the final design.

How does CNC Machining Work?

You now understand that CNC machining is a high-precision carving process in manufacturing. You also know that It turns digital designs into final products or parts. However, you may at this point be curious about the exact step-by-step process. How does it work?

1. Get Started with CAD Software.

You begin your CNC machining process by designing a digital 3D model. You achieve this by using computer-aided design (CAD) software. The likes of Fusion 360, SolidWorks and AutoCAD are all industry favorites. CAD software lets you draft virtual blueprints that define every dimension of the item you want.

"Grand View Research" is a trusted source and authority in the manufacturing space. In 2023 it reported the CAD software market growing globally by 7.5% year-on-year. The widening use of CNC processes has a lot to do with that. This has also encouraged competition and innovation among the makers of CAD software.

2. Turn Your CAD to CAM.

Now that you've completed your final design using CAD, a virtual draft is available with all its intricate measurements and details. Your CAD design is then processed using computer-aided manufacturing (CAM) software. CAM software converts your CAD design to G-code - the programming language used by CNC machines.

G-code can house precise command prompts down to the exact speed of the spindle during certain parts of the machining process. MIT's Machine Shop reports that 30% of total production time can me reduced through well-optimized CAM software.

Leading the CAM industry right now are brands like HSMWorks and MasterCAM.

3. Set Your CNC Machine and Process

Once you've successfully loaded your G-code onto the CNC machine, the machine's computer reads the instructions. It can now command the blade or edging tool precisely down a preset path. The best machines assure tolerances as accurate as 0.001 inches - thinner than hair.

4. Automate for Precision.

It's incredible how efficiency can be derived through automation. NASA says its CNC machined parts arrive with 99.8% fewer errors. That's because when you take away the chance of human error, manual machining can't compete with CNC machining.

CNC machining is an automated process. This means your desired components are made accurately, arrive faster and can be remade over and over again. Using CNC machining, you can scale up fast or slow down production. It is the backbone of car, medical, engineering, and aerospace industries.

Now you know how CNC machining works. Let's look at its key advantages and why so many industries rely on it.

✅️ Advantages of CNC Machining

You already know at this point that CNC processes produce consistent, high-quality parts. Have a look at the following five fact-based advantages of using CNC machining in your own production process.

1. You Secure Precision

The level of accuracy you can achieve with CNC machining can be as close as 0.001 inches. That's a figure so trustworthy, even NASA uses CNC processes. The aerospace giant makes many of its rocket parts and finishes this way.

Many of the common medical tools you can think of are made using CNC machining. Think of a scalpel or prosthetic, or even a stethoscope. All of these undergo some form of machining in their making, and its rarely done by hand.

There's also car makers, engineers, aeroplane makers and more. These are big and important industries that rely of consistent precision to get things done. You'll have a hard time finding industries where CNC machining is not used.

2. You Save Yourself Time

Adopting CNC processes lets you increase production rates. In 2022, the Journal of Manufacturing Systems reported that CNC machining can cut waiting times by half. Machines can operate at all hours of the day without stopping. This means your parts get made faster without the break times associated with manual work.

You can turn a week- or month-long order to one that takes just hours or days. In turn, you get to have your products onto the market faster than your competition.

3. You Save Costs

CNC machining lets you save on production costs. It can even lead to boosting your sales.

Using CNC processes allows you to save on manual labor costs. Beyond this, you can spread the cost of adoption across countless components. That is because CNC machining can produce a large variety of components and end products. While possible, it's rare to find CNC being commissioned for single use.

4. You Can Machine Many Materials

You'd be misled to think machining is only a metal process. While is it true that you can machine metals from aluminum to titanium, plastic, wood and stone can undergo CNC machining.

And you certainly won't be limited by the number of items you can produce. Better still, your material choices can be changed with minimal disruptions to the manufacturing process.

5. You Can Scale Your Business

At first, you may find yourself working with about 20 or so parts. There may be long waiting periods between ordering them and when they arrive. With CNC machining, your production can scale up exponentially in a matter of months.

Not only are lead times reduced, but design changes can be implemented quickly, too. This can be done without the need to train staff on new designs. You simply update the digital design and you're good to go. All this equal minimal manpower cost and increased production

CNC machining offers clear advantages for growing production. You may be experimenting on a new prototype. You may be confident enough to ramp up your existing production. Regardless, scaling your business through CNC machining secures accuracy, control and cost savings.

You've now learned exactly how CNC machining gives you precision, speed, and cost savings. You also know it works with multiple materials and scales with your business. These advantages make CNC essential for modern manufacturing.

The Most Common CNC Processes

Sometimes you need a component made but cannot decide on which CNC process to use. Rest assured - below is a tactful guide on the 5 most common CNC processing methods.

1. CNC Milling

For complex shapes, there is CNC milling. The milling process sees rotating cutters can being used. These cutters can move in multiple directions while the item being worked on remains fixed in place.

Benefits of CNC Milling

● The milling process allows you to carve out intricate pockets.

● It can carve out fine 3D contours and the most delicate slots.

● You can mill the hardest materials like titanium and the not-so-hard items like plastic.

● Tolerances of up to 0.001 can be achieved (SME Journal, 2023).

You go for CNC Milling when you need intricately made parts with the finest details.

2. CNC Turning

For all those round parts and curves, CNC turning is best. Using this process, you get to move the material around. This happens while the machining tool remains perfectly in place.

CNC turning is dedicated to producing items that move within each other. Think a hydraulic part or the shafts of engines. The making such curves requires moving precision with airtight seals.

Benefits of CNC Turning

● The process is proven to be 30% quicker than manual lathing.

● It results in far better finishes on the surfaces of curved components

● The process proves quicker for the high turnaround of round items in mass production

CNC Turning is the process you rely when you need rotating components and symmetry.

3. CNC Drilling

The drilling function is an important one. Automated through CNC, it allows you to make accurate, airtight slot holes. The precision offer is at level unchallenged by human effort. Imagine the creation of something as detailed as a circuit board or car engine. Those items need their holes drilled with super accuracy and at fast rates.

Benefits of CNC Drilling

● On average, you can produce about 50 holes a minute using CNC drilling. That's regardless of the material being worked on

● You can work on complicated designs.

● It allows to automate a drilling function that could otherwise take hours to complete.

If you're working in something that needs numerous precise hole drilled in rapid succession then CNC drilling is the solution for you.

4. CNC Grinding

The CNC method ideal for perfect finishes is CNC grinding. Sometimes the finishes on the parts you order have to be as smooth as a mirror. A part can require various textures on different sides.

Abrasive wheels are used during the machine grinding process. It is this process that allows for specified finished on machined surfaces. The process can even be used to sharpen and dull objects.

Benefits of CNC Grinding

● It can be applied to items as large as aeroplane propellers to tools as small as surgical scalpels.

● The process can be used to remove microscopic imperfections.

● It is perfect for upholding industry standards.

● CNC grinding can also be used to reduce friction between moving parts.

You will be using CNC grinding when the surface of the item you need has to be of the highest quality finish.

5. Combined CNC Processes

You may have thought of combining different CNC processes. This is common practice across all industries. A component or tool can need to be milled and drilled, or ground and turned. Because of this, it is not uncommon to combine different methods in the CNC machining process.

Here's a reassuring statistic. More than 67% of manufactures combine two or more CNC processes. That's according to an IMIS report published in 2024.

❎️ Disadvantages of CNC Machining

The advantages of CNC machining are needless to say, but you can't turn a blind eye to its drawbacks. Below STYLECNC will explain its main disadvantages in detail.

1. High Initial Cost

CNC machines (such as CNC milling machines, CNC lathes, CNC routers, 5-axis CNC machines) require a large upfront investment.

Setup and tooling costs: Custom fixtures, cutting tools, and programming can increase costs, especially in the case of small batches.

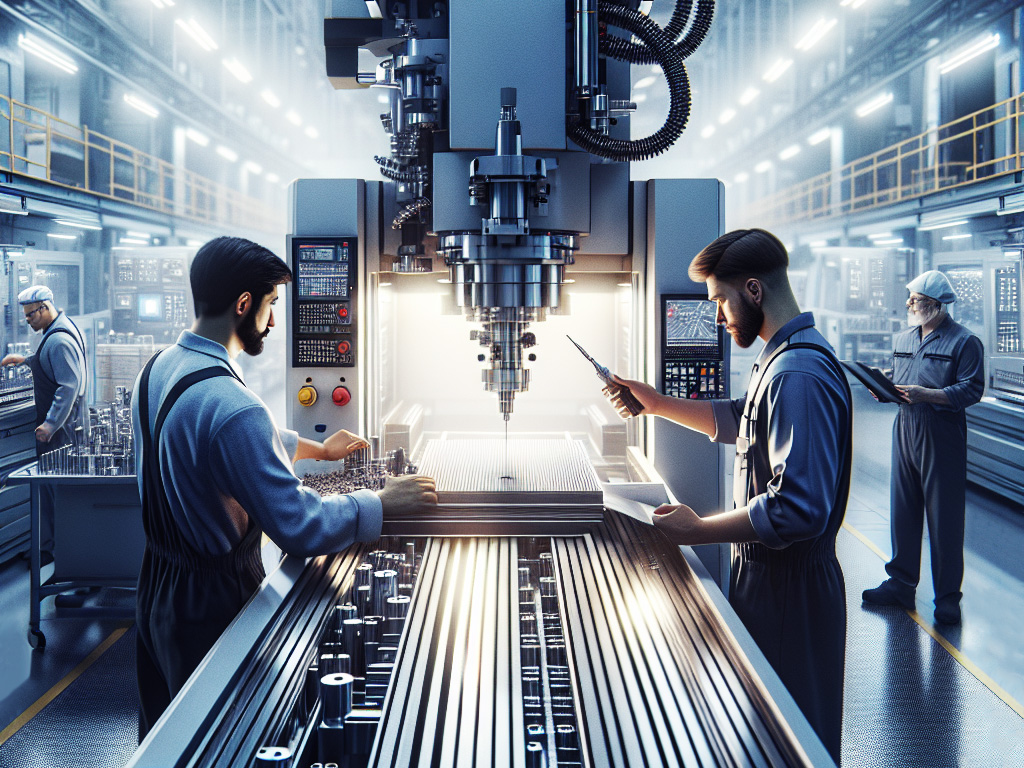

2. Skilled Operation Required

Although CNC reduces manual labor, it still requires skilled technicians (operators and programmers) for programming, setup, and maintenance.

Training costs: Operators need special training before they can take up their posts, which increases labor costs.

3. Material Waste

Subtractive manufacturing: CNC machining removes material, resulting in more waste compared to additive manufacturing (such as 3D printing).

Higher cost of expensive materials: Wasting materials such as titanium or Inconel can be costly.

4. Special Design Limitations

Although CNC can produce complex parts, some special designs (such as internal grids, chamfers) are difficult to achieve unless there is a multi-axis CNC machine.

Complex shapes are more expensive: Five-axis CNC machining can reduce limitations, but it will also increase investment costs.

5. Large Part Machining Limitations

The limited size of the CNC machining table precludes them from participating in certain large projects, requiring alternative machining methods.

6. Maintenance and Downtime

CNC machine tools require regular maintenance including lubrication, calibration and replacement of parts (e.g. spindles, ball screws).

Downtime failures may cause the production line to be interrupted or stopped.

7. Slow Mass Production

When it comes to very large batches (e.g. millions of parts), processes such as injection molding, stamping or die casting are more cost-effective.

8. Surface Finish Limitations

Achieving an ultra-smooth surface typically requires additional secondary operations such as polishing and grinding.

Conclusion

The advantages of CNC machining make it indispensable in modern industrial manufacturing, but its high initial cost makes small business owners discouraged, and CNC programming requires experience, which makes beginners lack confidence. In short, CNC machining comes with pros and cons. Whether a novice or a professional, everyone will play to their strengths and avoid their weaknesses to get what they need.

Final Take on CNC Machining

You've successfully explored the full potential of CNC machining. From its precision and speed, to the five key processes, you're all caught up. You can also see why it's the backbone of modern manufacturing.

With all this in mind, it might be great to have a trusted CNC machining partner at your side.

Leverage CNC Machining for Your Business

You are fully equipped to see how CNC machining delivers precision, speed, and scalability. All you have to do now is take action. CNC machining gives you the competitive edge, and at STYLECNC, we specialize in CNC machining services that match your exact needs.

If you need to truly understand CNC machining, you've found your partner and guide. Feel free to get in touch.

FAQs

What Is CNC?

CNC stands for "Computer Numerical Control," a manufacturing method in which CAM software directs automated machining from CAD designs.

What Is A CNC Machine?

A CNC machine is an automated manufacturing tool that uses computer-aided software to direct a tool to move along a CAD-designed path, working with most materials, such as wood, metal, plastic, foam, stone, and composites, creating precise cuts and engravings, millings as well as turnings.

Is CNC Machining Hard To Learn?

CNC machining requires knowledge and experience in CAD/CAM software and computer programming, and technical skills in geometry, tolerancing, trigonometry and measurement, as well as an understanding of G-code, tool paths and material properties. If you keep learning and practicing in the right way, you will eventually become a professional CNC machinist.

How Much Does A CNC Machine Cost?

The price of CNC machines varies depending on the type, model, size, purpose, features and brand, with used CNC machines starting at around $500, entry-level new CNC machines ranging from $1,000 to $5,000, small professional CNC machines costing at least $8,000, while some models go as high as $30,000 or more, and large industrial-grade CNC machines can cost over $100,000.

What To Consider When Buying A CNC Machine?

Whether you are a novice or a professional, when purchasing a CNC machine, you should consider your materials to machine, table size requirements, machine type (CNC router, mill, lathe, laser, plasma cutter and capabilities), work envelope and precision needs, budget and total cost of ownership, machine features and specifications, brand popularity, merchant reputation, after-sales technical support capabilities, software and controller compatibility, workshop space and power requirements, upgrade options and resale value. This will ensure you choose the right machine for your specific use case.