How to Calibrate the Precision of CNC Wood Router?

In order to ensure the high quality of woodworking, we should do a calibration work for the CNC wood router before woodworking.

In order to ensure the high quality of woodworking, you should use high precision CNC wood router. Before woodworking, we should do a calibration work for the CNC wood router. We can calibrate the precision through the following two ways.

Manual Calibration

We can put down the plane line of CNC wood router, start the spindle, and then measure manually. You should stop when got a suitable location. In order to ensure the precision, you can measure on a right position, Of course, the different materials of table will affect the results of the measurement.

Computer Calibration

Computer calibration is more simple compared to the manual calibration, we can open the settings panel of CNC wood router to set, calibrate the precision of CNC wood router through the test path, save the path directly after alignment.

Share This Article With Others

Further Reading

2020-03-152 Min Read

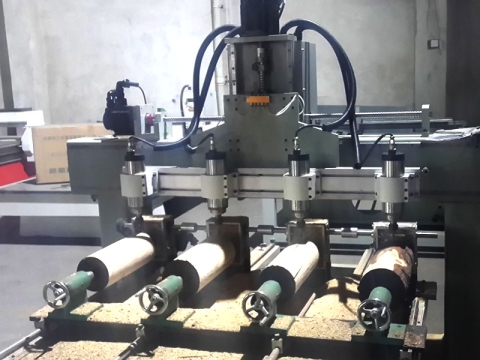

A lot of users choose multi head CNC router because of its special features and advantages for woodworking, sign making, decorations, arts and crafts.

2023-08-317 Min Read

In this article, you will understand what is CNC programming for beginners, how to use the best CAD/CAM software to create personalized programs for programmers in modern industrial CNC machining.

2026-01-306 Min Read

The global CNC router market grew 8.2% from $16.05B to $17.37B. Industry projected to reach $25.62B by 2030. See growth drivers, segments & regional analysis.

2025-07-307 Min Read

Are you struggling to find a reliable portable CNC machine? Here's a professional user guide to give you tips on choosing the right machine tool for your needs.

2019-01-184 Min Read

CNC router is a tool controlled by a computer. it only becomes more sophisticated when considering how the computer controls the tool.

2023-10-075 Min Read

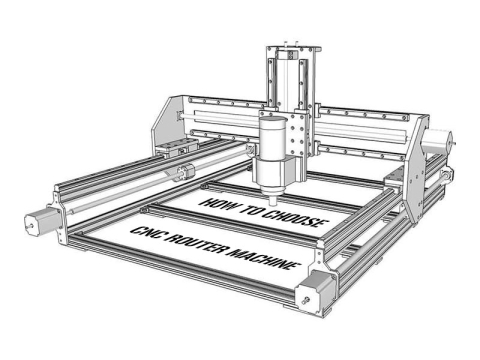

Most people only consider the low cost when choosing a CNC router machine. However, we really need to consider both the price and applicability. If you buy a CNC machine at a cheap price, but it is not suitable for your work, then it's just like a pile of scrap iron.