Improve the working efficiency of CNC wood router is equal to improve the production efficiency, the development of the enterprise is very necessary. People continue to improve the performance of CNC wood router, function, and strive to create more value for the enterprise. So improve the working efficiency of CNC wood router is the best embodiment. However, to improve the working efficiency of CNC wood router methods have many aspects, small series from the carving machine on the depth of the carving depth of the analysis to improve the working efficiency of woodworking caving tips.

1. According to the different materials to determine the different cutting depth.

Because of the different materials of the tool will have a maximum depth, we used woodworking engraving machine for processing time, try not to with the tool of the maximum depth processing, long processing time and tool damage faster. But in the process the maximum cutting depth when the speed is not up, high speed is likely to cause broken. So we might as well put the knife is set to 2 / 3 of the maximum amount of, this tool life will greatly increase, processing speed also can improve a lot; in this way can save tools cost, but also can improve the machining efficiency.

2. According to the thickness of the cutting material to determine the depth of the cutter.

According to the actual situation, we must first carry out rough machining, and then finish the finishing. When the rough machining, as far as possible to remove all the margin, saving finishing time; can also be used to better processing performance of the tool material. CNC wood router performance is not only reflected in the hardware configuration of the machine, but also need our long-term accumulation of processing experience, to improve the processing efficiency of CNC wood router.

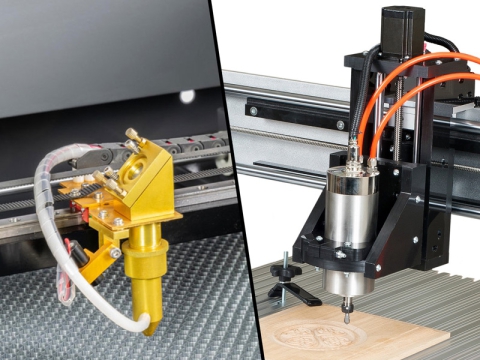

In short, whether it is a CNC wood router, or a stone cnc router, the key point is according to the performance of the carving material hardness and engraving tool to determine a reasonable cutting parameters, so as to play advantages of CNC router, achieve the expected effect of the sculpture, these are the key points to improve the work efficiency of CNC wood router, you got it?