Definition

CNC lathe is the abbreviation of digital control lathe, which is an automatic lathe equipped with a program control system. The control system can logically process programs with control codes or other symbolic instructions, and decode them, so as to make the lathe run and process parts.

CNC lathe is a mechatronics product integrating machinery, electrical, hydraulic, pneumatic, microelectronics and information technologies. It is a machine tool with the advantages of high precision, high efficiency, high automation and high flexibility in mechanical manufacturing equipment.

Features

Compared with ordinary lathes, CNC lathes have the following features:

1. High processing precision and stable processing quality;

2. Multi-coordinate linkage can be carried out, and parts with complex shapes can be processed;

3. When machining parts change, generally only need to change the NC program, which can save production preparation time;

4. The lathe itself has high precision and high rigidity, can choose a favorable processing amount, and has high productivity (generally 3 to 5 times that of ordinary machine tools);

5. The lathe has a high degree of automation, which can reduce labor intensity;

6. The requirements for the quality of the operators are higher, and the technical requirements for the maintenance personnel are higher.

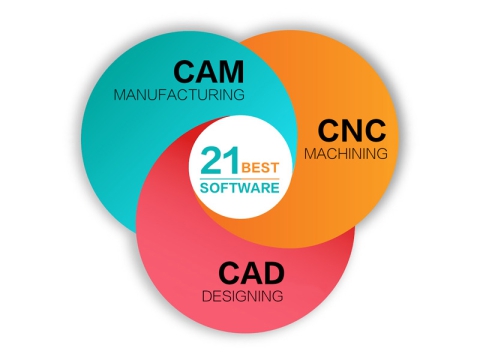

CNC Controller

The CNC controller uses a computer to realize the digital program to control the operation of the lathe. This technology uses a computer to execute the sequential logic control function of the movement track of the device and the operation of the peripherals according to the control program stored in advance. As a computer is used to replace the original numerical control device composed of hardware logic circuits, the storage, processing, calculation, and logic judgment of input operation instructions can be realized by computer software, and the microscopic instructions generated by the processing can be transmitted to The servo drive device drives the motor or hydraulic actuator to drive the equipment to run.

Traditional mechanical processing is performed by manual operation of ordinary lathes. During processing, the mechanical tool is shaken by hand to cut wood, and the accuracy of the product is measured by the eye with tools such as calipers. Modern industry has already used computer digitally controlled machine tools for operations. CNC lathes can automatically process any products and parts directly according to the procedures programmed by technicians in advance. This is what we call CNC machining. Numerical control processing is widely used in any field of all mechanical processing, and it is the development trend and important and necessary technical means of mold processing.

Applications

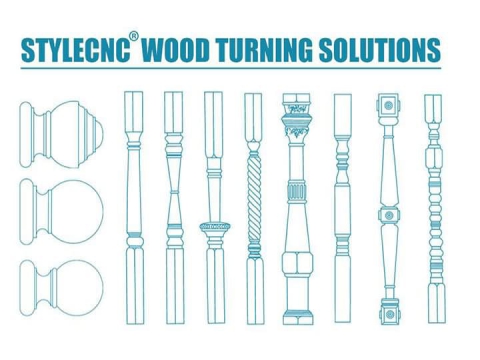

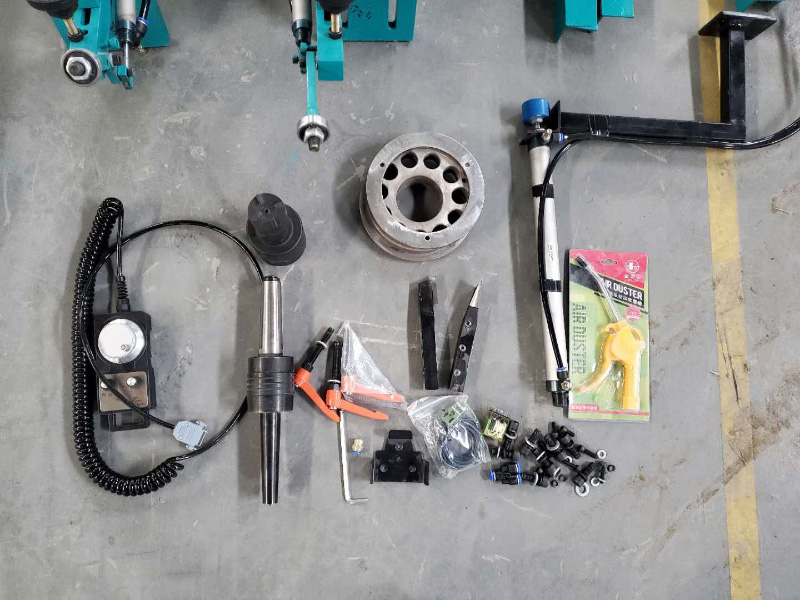

CNC wood lathe is a high-tech product integrating mechanical, electrical and pneumatic. It is suitable for workpieces with large diameter and short length. Hardwood and cork stickers can be processed with high-speed steel or cemented carbide tools, and rough and fine processing such as circle, inner hole, end face, cone, cutting, and cutting can be completed. Realize full automation and complete products at one time, which greatly improves the efficiency of CNC wood lathes. It is mainly used for processing columns, wooden bowls, pens and other handicrafts, as well as other workpieces with rotating surfaces. It is a machine tool widely used in weapon manufacturing. Rotating machinery such as milling machines and drilling machines are extended from lathes.

CNC wood lathes are mainly used to process various staircase columns, table and chair legs, Roman columns, basins, wooden vases, sticks, wooden column tables, wooden furniture, children's bed columns, etc. It can also process plates, stemware, bottle caps, cup lids, cup lids, handles, rolling pins, flutes, flutes, suona, cello accessories, etc. It is especially suitable for mass production of small and medium-sized woodworking enterprises. The shape can be flexibly set at any time and the processing style can be quickly changed. In traditional lathe processing, only one product can be processed at a time. The CNC lathe has dual-axis, dual-axis, and three-axis CNC wood lathes, which can process two or three products at the same time, with the same size and size. The operation is simple, the drawing is convenient, easy to understand, the product style of one-click conversion, and no professional knowledgeable personnel can carry out a little training. Fully automatic CNC wood lathes can operate 2-3 sets at the same time, which greatly improves processing efficiency, saves labor, saves money, and brings good economic benefits.