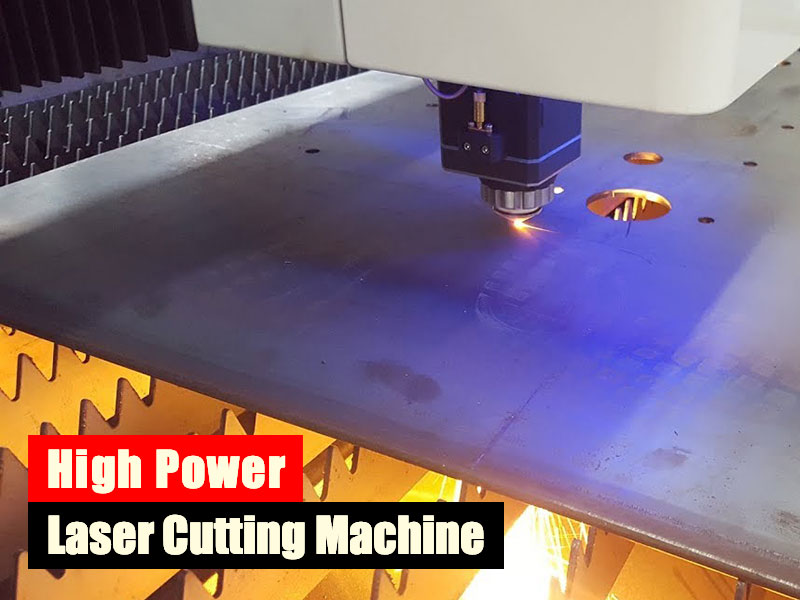

High power laser cutting machines have a wider range of applications than general low- and medium-power lasers. Because of their high power, there is no problem in cutting plates and workpieces of various thicknesses, so they can be widely used in steel, metallurgy, industrial manufacturing, shipbuilding, and aviation. Large-scale projects such as aerospace and railways are under construction.

In recent years, with the breakthrough of laser technology, high-power laser cutting machines have made considerable progress, from 6000W in 2017 to the current 10,000W level, and even 60,000W in 2021.

High-power laser cutting machines not only have cutting performance advantages over traditional cutting methods, but also have advantages in cutting thickness compared to low- and medium-power laser cutting machines. Small and medium-power laser cutting machines have limited cutting thickness, while high-power laser cutting machines can not only cut thin plates, More able to cut thick plates.

Unlike flame cutting, although the laser cutting machine also cuts metal plates, because laser cutting uses light energy, the finished product after cutting does not need to be polished, and there will be no errors and deformations like flame cutting products. .

In the context of global intelligent manufacturing, both social and economic development and breakthroughs in laser technology will give birth to a broad market for laser cutting machines. The breakthrough of laser technology has accelerated the advancement of laser cutting machines in the direction of high-power, high-precision, and large-format. At the same time, the manufacturing industry under the background of intelligent manufacturing is showing a trend of transforming from traditional processing to high-end manufacturing, and laser cutting has been increased. Demand, which inspired the laser cutting machine to maintain a high-speed development trend.

With the development of the world economy, major projects such as railway construction, highway construction, water conservancy construction, hydropower construction, energy, mining construction, construction industry, aerospace, shipbuilding and other major projects are adv High-power laser cutting machines can just solve these problems, and are more efficient and accurate than traditional cutting methods, so high-power laser cutting machines will be widely used in the world's construction machinery industry.

The metal processing industry occupies an important part in the industrial design and manufacturing system. Many metal materials can be cut without deformation regardless of their hardness. Therefore, the ultra-high-power fiber laser cutting machine technology has obvious advantages, but as a high-tech equipment, to use the ultra-high-power fiber laser cutting machine to achieve the ideal cutting effect, it is also necessary to master its processing technical parameters and operating procedures. Especially in the cutting process of metal laser cutting machine, you must choose the appropriate cutting speed, otherwise it may cause several bad cutting results. The main manifestations are as follows:

What effect will the cutting speed of the high-power fiber cleaver have?

When the laser cutting speed is too fast, it will cause the following undesirable results:

1. Causes the phenomenon of inability to cut and random sparks;

2. Cause the cutting surface to show diagonal stripes, and melt stains on the lower half;

3. Cause the entire section to be thicker, and no melting stains are generated.

On the contrary, when the laser cutting speed is too slow, it will cause:

1. The cutting surface is rough, causing over-melting;

2. The slit becomes wider and melts at the sharp corners;

3. Affect the efficiency of cutting.

Therefore, in order to make the ultra-high-power fiber laser cutting machine better perform its cutting function, you can judge whether the feed speed is appropriate from the cutting spark of the laser equipment:

1. If the sparks spread from top to bottom, it indicates that the cutting speed is appropriate;

2. If the spark tilts backward, it indicates that the feed speed is too fast;

3. If the sparks appear to be non-spread and less, and condensed together, it indicates that the speed is too slow.

Compared with other traditional metal cutting methods, high-power laser cutting technology has incomparable obvious advantages. The high-power laser cutting machine not only has the main characteristics of narrow slits and small workpiece deformation, but also laser cutting has the advantages of fast speed, high efficiency, high quality, high reliability, first-class cutting quality, improve production efficiency, and shorten production cycle. Mastering the use methods and properties of high-power laser cutting machines can enable industrial production in all walks of life to reach higher milestones.