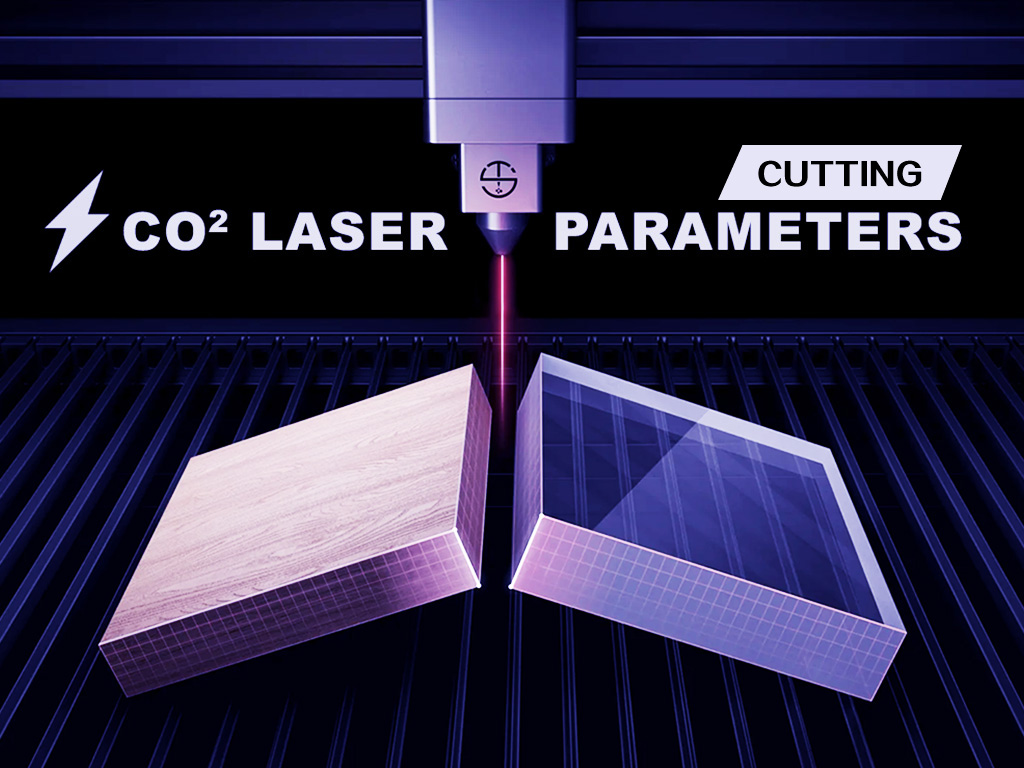

A CO2 laser cutter is a thermal cutting tool that can cut a variety of non-metallic materials, including wood, acrylic, paper, leather, fabric, rubber, and foam. CO2 lasers are ideal for cutting materials with high absorption rates at the laser wavelength, offering fast cutting speeds and high precision.

CO2 lasers can cut through materials of varying thicknesses at various speeds, depending on laser power, as well as material type and hardness. Higher power lasers are capable of cutting thicker materials at faster speeds. In most cases, CO2 laser cutters work with a power range of 40 watts to 300 watts to cut through wood with a thickness of 1 mm to 20 mm at a speed of 1000 mm/min to 9000 mm/min, acrylic with a maximum thickness of 40 mm at a speed of around 1200 mm/min, leather and cloth with a thickness of 0.75 mm to 10 mm at a speed of 500 mm/min to 12000 mm/min, and paper with a thickness of 0.5 mm to 11 mm at a speed of about 3000 mm/min.

Best CO2 Laser Cuttable Materials

Wood

• Solid wood (such as birch, poplar, red oak, cherry)

• MDF (medium-density fiberboard)

• Plywood

• Cork

Plastics

• Acrylic

• PP (polypropylene)

• PVC (polyvinyl chloride)

• ABS (acrylonitrile butadiene styrene)

Paper

• Paper Sheet

• Cardstock

• Cardboard

Leather & Fabric

• Organic fabrics (such as polyester)

• Line fabric (multi-layer)

• Artificial fabric (chemical fiber fabric)

• Leather (genuine leather and artificial leather)

Foam (Polystyrene)

• HIPS

• EPS

• XPS

CO2 Laser Cutting Thickness & Speed & Kerf Chart

| Material | Thickness (mm) | Speed (mm/min) | Assist Gas | Kerf (mm) |

|---|---|---|---|---|

| Organic Glass | 10 | 800 | N2 | 0.7 |

| Polyester Felt | 10 | 2600 | N2 | 0.5 |

| Line Fabric (Multi-layer) | 15 | 900 | N2 | 0.5 |

| Cardboard | 0.5 | 3000 | N2 | 0.4 |

| 2.6 | 3000 | N2 | 0.5 | |

| Quartz Glass | 1.9 | 600 | 0.2 | |

| PP (Polypropylene) Sheet | 5.5 | 700 | N2 | 0.5 |

| Polystyrene Sheet (HIPS, EPS & XPS Foam) | 3.2 | 4200 | N2 | 0.4 |

| PVC Sheet | 4 | 1700 | Air | N/A |

| Organic Glass | 10 | 1200 | ||

| Bakelite Board | 5 | 2100 | ||

| Fiberboard | 15.6 | 4500 | N2 | |

| Multi-layer Plywood | 6.2 | 9000 | ||

| PVC (Polyvinyl Chloride) Laminate | 3.1 | 10500 | ||

| Chipboard | 3.9 | 18000 | ||

| 3.1 | 22500 | |||

| Acrylamide Board | 2.8 | 33900 | ||

| 3.2 | 29700 | |||

| 3.2 | 29700 | |||

| Acrylic | 2.0 | 1000 | N/A | |

| Artificial Leather | 0.8 | 2500 | ||

| Gypsum Board | 9.0 | 500 | ||

| Plywood | 10.0 | 1100 | ||

| Heat-Resistant Glass | 2.2 | 500 | ||

| Rubber Sheet | 5 | 500 | ||

| Leather | 4 | 2200 | ||

| Artificial Fabric | 6.5 | 2200 |

CO2 Laser Power and Cutting Thickness Chart

| Material | Laser Power | ||||

|---|---|---|---|---|---|

| 40W | 50W | 60W | 80W | 100W | |

| Cutting Thickness | |||||

| Acrylic | 3mm | 5mm | 5-8mm | 6-10mm | 10-12mm |

| MDF | 1mm | 2mm | 4mm | 5mm | 6mm |

| Plywood | 3mm | 5mm | 8mm | 10mm | 13mm |

| PVC | 2mm | 3mm | 4mm | 5mm | 8mm |

| Rubber | 2mm | 2mm | 3mm | 4mm | 5mm |

| Leather | 2mm | 3mm | 4mm | 5mm | 7mm |

| Fabric | 2mm | 3mm | 4mm | 6mm | 7mm |

| Paper | 3mm | 4mm | 5mm | 7mm | 8mm |

| Material | Laser Power | ||||

|---|---|---|---|---|---|

| 130W | 150W | 180W | 220W | 300W | |

| Cutting Thickness | |||||

| Acrylic | 12-25mm | 17-28mm | 20-30mm | 20-35mm | 20-40mm |

| MDF | 8mm | 10mm | 10mm | 12mm | 18mm |

| Plywood | 15mm | 15mm | N/A | N/A | N/A |

| PVC | 9mm | 10mm | N/A | N/A | N/A |

| Rubber | 6mm | 7mm | N/A | N/A | N/A |

| Leather | 8mm | 10mm | N/A | N/A | N/A |

| Fabric | 8mm | 10mm | N/A | N/A | N/A |

| Paper | 10mm | 10mm | N/A | N/A | N/A |

All charts are for reference only. The actual cutting thickness will vary depending on material properties and cutting parameters such as power and speed.