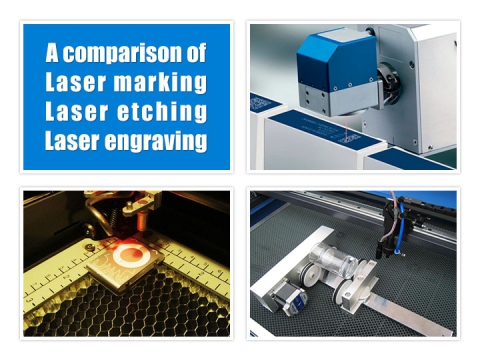

1. Laser Source Differences:

The optical system of laser engraving machine is consist of three mirrors and one pcs lens, laser source is co2 glass tube. The life of the glass tube laser is usually less than 2000 - 10000 hours. CO2 glass tube lasers are disposable.

The laser source of laser marking machine is a kind of metal tube laser, the lifespan is expectancy in more than five years. The metal tube of the laser marking machine can be inflated again and recycling. The lifetime of the solid state laser can be replaced after the semiconductor module.

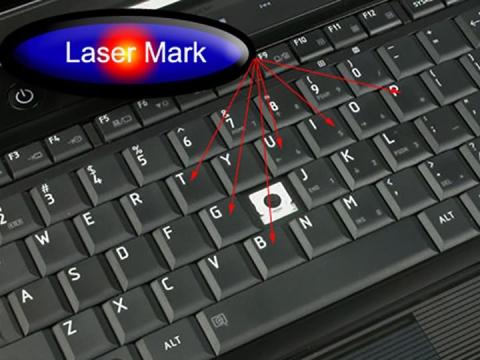

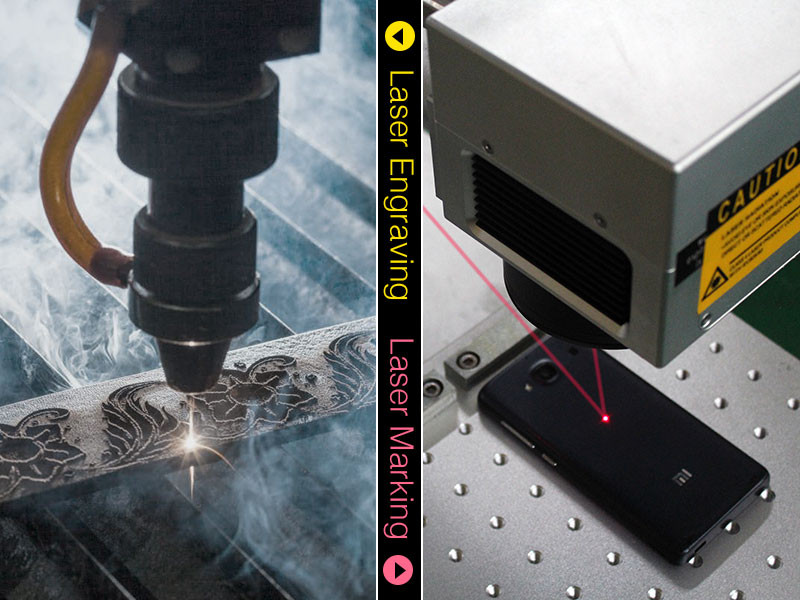

2. Machining Materials Differences:

The laser engraving machine can work on many different materials, including glass, crystal, acrylic, all kinds of wood, stone, fabric, leather, paper, PVC, plastic, mosaic, and other nonmetal materials. And the laser marking machine can be used for all kinds of metal and nonmetal materials.

3. Working Area Differences:

Laser engraving machine has a range of different processing area, such as: 600*400mm, 900*600mm, 1300*900mm, 1400*1000mm, 1300*2500mm, 2000*3000mm, and so on, laser engraving machine has a larger working area. Otherwise, the working area for laser marking machine is smaller, such as 110*110mm, 220*220mm, 300*300mm and so on, if the area is too large, then the laser marking machine is not very stable.

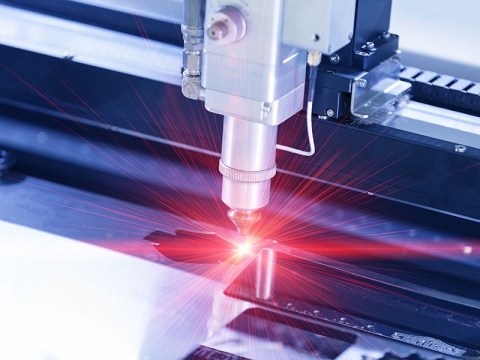

4. Machining Depth Differences:

The laser engraving machine can engrave in high deep, laser power ranging from 60W to 150W. The depth of the material is also from 0.1mm to 80mm, engraving depth according to the specific materials. And laser marking depth is generally less than 5mm, it main mark on the surface of materials, the laser rate is also between 10W to 100W.

5. Machining Speed Differences:

The laser engraving machine max cutting speed 200mm/s, max engraving speed is 500mm/s; The laser marking machine speed is three times than the speed of laser engraving machine. In the speed, the laser marking machine is significantly faster than the laser engraving machine.

6. Working Principle Differences:

Laser engraving machine is use laser to engrave on the work piece, The laser marking has 3 types working principle, one is with laser beam evaporate material surface so as to expose the deeper material, the second is make the materials surface to come up the chemical or physical changes and carving out trace, the third is through the laser energy burn some parts of material to show the etched graphics, text.