Laser engraving machines are generally used for cutting and engraving materials. The laser engraving can be divided into three types: cutting engraving, concave engraving and convex engraving. The material removal principle of laser engraving is the same as that of laser cutting, and multiple uncut slots are connected together to form an area of material removal. The cross section of the laser grooving is "V" shape, the lower the cutting speed, the greater the laser current, the larger the grooving width and depth, in which the cutting speed and laser current have a greater influence on the grooving depth than the grooving width Much more.

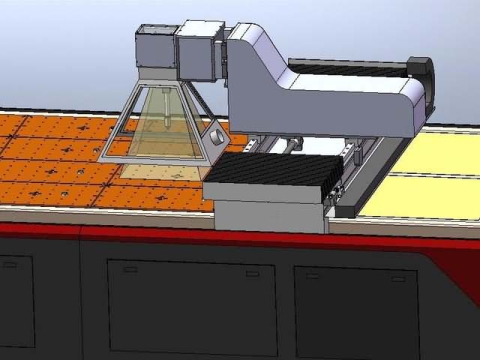

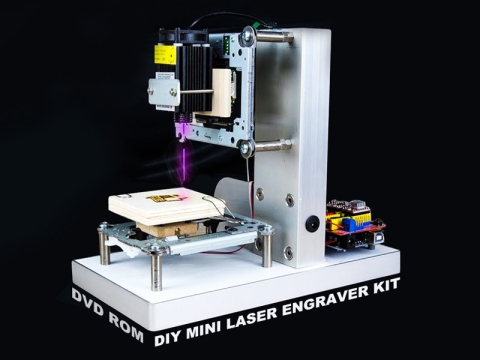

Working Principle

The basic principle of laser engraving is basically the same as that of laser cutting, which uses high-energy density laser beam to convert into thermal energy, which causes thermal decomposition and carbonization of the material instantly, thereby removing part of the material. Laser cutting is to separate the different parts of the material (mainly the board), and laser engraving is to process the required patterns, patterns and text on the surface of the wooden material. For the same material, the energy required for laser cutting is relatively large, and laser engraving requires relatively little energy because it does not need to cut through the workpiece.

Benefits

Laser engraving is a non-contact processing method. Compared with traditional machining methods, it has the advantages of no debris pollution, no tool wear, no need to change tools, and no noise pollution (noise is very low). The focusing lens of the laser cutting head focuses the laser to a very small spot with a spot diameter of generally 0.1 to 0.5 mm. The focus of the laser beam is located near the surface to be processed to melt or vaporize the processed material. At the same time, the air flow coaxial with the beam is ejected from the cutting head, blowing the melted or vaporized material from the bottom of the cut.

Types

Cutting Engraving.

It uses the cutting method to process the required pattern on the surface of the material, that is, the pattern is first decomposed and expressed into several line forms, and then these lines are cut by laser, and then the pattern represented by the cutting line is obtained.

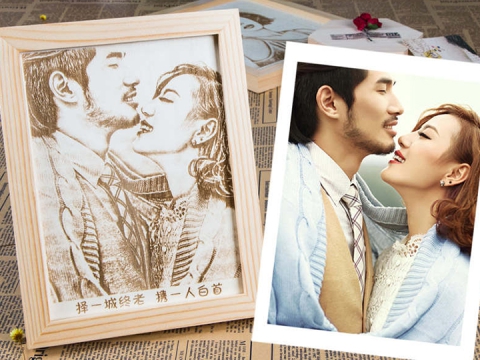

Concave Engraving.

Cut away the part of the pattern, and leave the surface of the material as it is for the part around the pattern. There are two cases here. The first case is the same cutting force for each point on the pattern. The engraved pattern is mainly reflected by the outline shape. The second case is based on the distribution of the light and dark and contrast of the pattern. The "dark" part of the pattern is cut more, and the "bright" part of the pattern is cut less or not. The former is suitable for engraving characters, animals, plants and other patterns that are mainly based on appearance, while the latter is more suitable for engraving patterns with details such as facial expressions of characters.

Convex Engraving.

Contrary to concave die engraving, this engraving process only cuts the material around the pattern, and the cutting force at each point is the same, but the material of the pattern itself is not cut. This engraving method is suitable for the expression of text, graphic outline, etc. In the latter two engraving methods, the method of material removal is that each time the laser head walks on the cut surface, a linear groove is cut, and then the next line is cut after moving a small distance. Usually the distance between the two slots can be O. 05-0.5mm. In this way, multiple linear cuts are used to achieve the purpose of removing the area-forming material required by these two engraving forms. Of course, in the second form of concave die engraving, the size of the groove, especially the depth of the groove, will change as needed on the same cutting line.