The working mode of the hand-held optical fiber welding machine, holding welding in hand, is flexible and convenient, and the welding distance is longer. Replace the fixed optical path with a hand-held welding gun. The handheld fiber laser welding machine is mainly used for laser welding of long-distance and large workpieces. The heat-affected area during welding is small, which will not cause work deformation, blackening, and traces on the back. The welding depth is large, the welding is firm, and the melting is sufficient. There is no sag phenomenon when the convex part of the molten material in the molten pool converges with the substrate! The handheld laser welding machine subverts the working mode of the previous laser welding machine, and replaces the previously fixed optical path with a handheld welding gun. This mode of operation not only facilitates the welding of products such as molds, advertisements, kitchen utensils, doors and windows, but also makes it possible to operate laser welding outdoors. This heralds the replacement of laser welding for the last field of traditional welding such as spot welding and argon arc welding.

Compared with traditional argon arc welding, hand-held laser welding improves the efficiency by more than 50%, smooth and even. It is easy to grind or does not need to be polished after welding. Now it has debuted at the C position of the laser circle. However, while holding the convenience of handheld welding equipment, we should put laser safety first.

At present, due to the improper use of the operator, there have been many safety accidents: some leaked light from the welding head burned the leg; some were laser beam damage to the user's fundus retina; some reflected laser light ignited the surrounding flammable materials and caused a fire, etc. As a result, the impact will cause users to suffer for life, and manufacturers will also face huge claims. The source of all these accidents reflects the hidden dangers behind the current explosion of handheld welding equipment, the safety measures of welding equipment are not reasonable enough, and users have not received good safety training.

From a certain perspective, handheld laser welding equipment is like holding a laser gun, which is extremely dangerous for non-professionals to operate.

1. Popularization of Knowledge: Rigorous training before taking up posts.

Educate and train the staff who operate the handheld fiber laser welding machine to make the operator understand the potential risks that may appear when operating the handheld laser welding equipment, suspend the appropriate laser safety exercise for the operator, and emergency treatment methods when the risk is presented. Furthermore, the management and use of lasers must be terminated by professionals, and untrained and educated personnel shall not open and use laser machines without authorization. The relevant person in charge of Shenzhen Minglei Laser Equipment Co., Ltd. suggested that when the machine is delivered to the customer, it is necessary to strictly carry out standardized operation training, and paste the operation requirements in a conspicuous place on the operation site. For the machine to operate normally, it is necessary to open the host enable switch and hand. Hold the gun head power switch, press and hold the light button three switches to prevent accidental accidental injury. When the machine is delivered to the customer, it is necessary to strictly carry out standardized operation training and paste the operation requirements in a conspicuous place on the operation site.

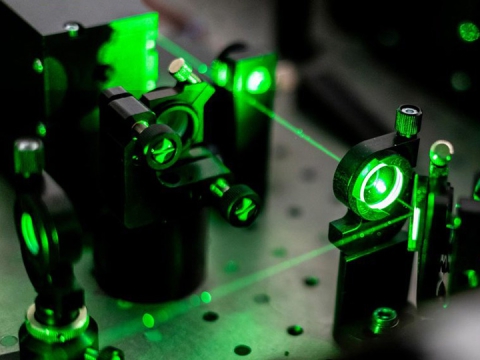

2. Anti-beam Radiation: Wear radiation protective glasses and protective clothing.

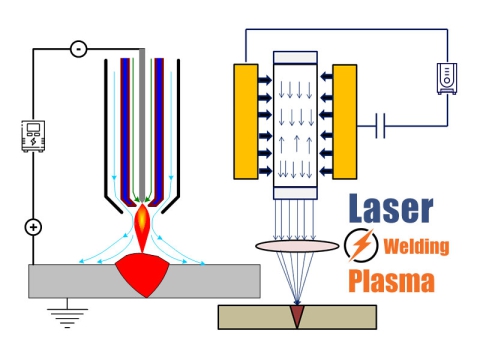

As we all know, the laser of the laser welding machine is the light energy radiation emitted by the excitation and is a kind of high-intensity light. The laser light emitted by the laser source is generally considered to be free of physical harm when it is not in contact or invisible; but The laser welding machine will cause ionizing radiation and stimulated radiation during the welding process. This induced radiation will not affect the eyes and the body.

Although the laser beam is very small, the operator generally likes to stare at the beam of the welding machine, but if the sparks produced by cutting for a long time are harmful to the eyes, there will be a tingling sensation. The retina is a very sensitive organ, so the operator must wear a pair of radiation protective glasses in the case of long-term exposure to the light source.

For hand-held welding equipment made with fiber lasers, when the power exceeds 1000W, the user needs full body protection. Just one spectacle is not enough, because bare skin will suffer burns. Therefore, during the operation, the operator should wear protective clothing to protect his safety to the greatest extent.

3. Working Environment: Strictly abide by the hygiene standards.

A large amount of ozone and oxynitride will be generated during the laser welding process; especially the ozone concentration far exceeds the reference health standard, which has a great impact on human health.

Therefore, there must be a good ventilation device at the work site to discharge harmful gases and metal dust. In addition to this, in addition, fire protection equipment, such as sand boxes, fire extinguishers, fire hydrants, buckets, etc. must be provided. The distance of flammable materials to the welding place shall not be less than 5m. If the specified distance cannot be met, it can be properly covered with asbestos board, asbestos cloth, etc. to prevent Mars from falling into flammable objects. The distance between explosive materials and welding station shall not be less than 10m.

4. Equipment Selection: Quality is the most important.

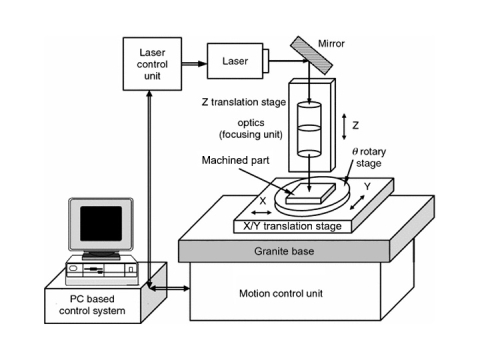

According to laser safety standards, handheld laser welding equipment belongs to the highest safety level of high-power laser equipment. Therefore, when an unknown object enters the optical path, the automatic stop of the laser power is a mandatory function.

At present, many businesses are developing new technologies that have greatly improved the safety of handheld laser welding equipment. For example, a handheld welding head with target recognition function, such as a handheld welding head that can be intelligently monitored in real time, and timely warning of failures. STYLECNC recommends: When processing thorium tungsten and cerium tungsten electrodes, sealed or exhaust-type grinding wheels should be used for grinding. Operators should wear masks, gloves and other personal protective equipment, and wash their hands and faces after processing. Furthermore, thorium tungsten and cerium tungsten It should be kept in an aluminum box.