The success of your machining projects depends on the software you use for CNC programming. The accuracy, effectiveness, and general caliber of your work are directly impacted by the program you choose. We will examine some of the top CNC programming software choices in this tutorial, which is intended for both novices and experts. This article aims to provide you a thorough review of all available options, from free to premium, so you can make an informed choice.

Importance of Choosing the Right CNC Programming Software

Choosing the foundation of your machining process involves more than simply picking a tool when selecting the best CNC programming software. You may save time and money by streamlining your workflow and minimizing mistakes with the help of the correct software. Making the correct decision is crucial, regardless of your status in the industry, hobbyist, small company owner, or professional.

Selecting the software that best meets your needs might be difficult with so many alternatives available. A number of factors come into play, including the kind of job you're performing, compatibility with your system, and convenience of use. Gaining insight into these elements' significance will help you choose wisely and improve your CNC machining experience.

What is CNC Programming Software?

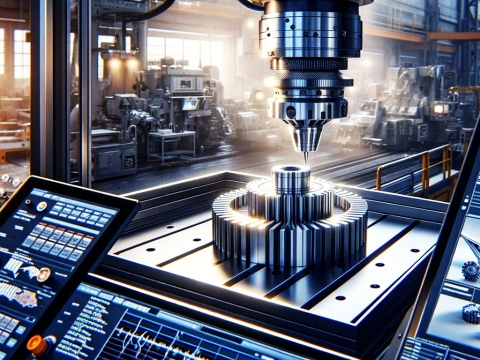

One kind of computer software used to write the instructions that control CNC machines is CNC programming software. The machine is instructed on how to move, where to cut, and how fast to run by these commands, which are referred to as G-Code. Your design files are essentially translated into machine-readable code by CNC programming software, which the CNC machine can then comprehend and run.

Software for CNC programming comes in a variety of forms, each with a distinct function. While some software is designed with the creation of 2D and 3D models in mind, others concentrate on toolpath and G-Code development. Many contemporary CNC software programs provide consumers a comprehensive bundle by combining design and programming features. Your machining projects' precision and efficiency may be significantly increased with the use of the correct software.

Top CNC Programming Software for Beginners

It might be difficult to choose the best CNC software if you're just starting out, but there are solutions that are easy to use that can help you get started with CNC programming. With their emphasis on simplicity, these apps provide guided stages and user-friendly interfaces so that you may learn without feeling overwhelmed. The following are some of the best CNC software choices that are ideal for novices.

1. Carbide Create

Overview: For beginners, Carbide Create is a great free CAD/CAM program. It is perfect for beginners who have never used a CNC because it provides basic design capabilities and easy G-Code development.

Features include customizable toolpaths, integrated post-processing for several well-known CNC machines, and user-friendly 2D sketching tools.

Why It's Beneficial for Novices: Even users with little experience can easily go from designing simple ideas to machining thanks to Carbide Create's user-friendly interface.

2. Easel by Inventables

Overview: Easel is a web-based CNC solution that combines CAM and CAD capability into a single platform. It is especially well-liked by beginners and lovers of woodworking.

Features: One-click G-Code production, pre-configured material parameters, and drag-and-drop design elements are among the features.

Why It's Beneficial for Novices: Easel's assisted design process and installation-free web platform make it easier for novices to construct projects.

3. Fusion 360 for Personal Use

Overview: Fusion 360 is ideal for enthusiasts because it comes with a free personal use license. Although this program is a little more difficult, anyone who wants to learn can still use it.

Features include integrated CAM toolpath development, simulation, and 3D modeling.

Why It's Beneficial for Novices: From basic to intermediate skill levels, Fusion 360 offers a great path, with more sophisticated capabilities available as you progress. It is therefore beneficial for novices.

Advanced CNC Programming Software for Professionals

CNC experts can accurately accomplish challenging tasks with the resources provided by modern software. To satisfy the requirements of industrial applications, these programs provide enhanced control, customizable options, and sophisticated capabilities. These are some of the greatest choices for seasoned users.

1. Mastercam

Overview: One of the best CAD/CAM manufacturing software packages is Mastercam. It provides a large selection of multi-axis, 2D, and 3D machining tools.

Features include substantial machine library support, innovative toolpath techniques, and dynamic motion technology.

Why Professionals Should Use It: Experts who require control and precision in intricate machining jobs will discover that Mastercam's flexible and strong features are appropriate.

2. SolidCAM

Overview:SolidCAM is an integrated CAM software for SolidWorks, known for its seamless workflow and powerful machining solutions.

Features: iMachining technology for faster and safer toolpaths, full associativity with SolidWorks design changes, and multi-axis machining capabilities.

Why It’s Ideal for Professionals: SolidCAM’s deep integration with SolidWorks ensures that your design and machining processes are fully synchronized, reducing setup time and enhancing productivity.

3. PowerMill

Overview: Autodesk created PowerMill, a tool for high-speed, five-axis milling. It is employed in the mold-making, automotive, and aerospace industries.

Features: Features include improved surface finishing techniques, collision avoidance, and high-efficiency roughing.

Why Professionals Should Use It: Because of its emphasis on high-performance machining, PowerMill is a great option for demanding industrial applications where speed and accuracy are essential.

Are Free CNC Programming Software Worth It?

If you are just starting out or have a tight budget, free CNC programming software may be a tempting solution. But not all free software offers the functionality or dependability required for work-related use. Here are some things to think about when assessing choices for free CNC programming.

Benefits of Free CNC Programming Software

The primary benefit is, of course, that it is risk-free, making it an excellent place to start. Learning the fundamentals without having to pay for software can be done rather well using free options. Many of the free choices have easier-to-use, more straightforward interfaces and are geared toward beginners.

Drawbacks of Free CNC Programming Software

Free software frequently lacks sophisticated functionality that are present in commercial versions, which can be problematic for intricate tasks. Free tools might not have frequent updates or strong customer support, which could result in bugs or compatibility problems. On larger projects, the slower or less efficient nature of free software can have an effect on productivity.

Key Features to Look for in CNC Programming Software

Make sure the features of the CNC programming software you choose fit your demands. The quality of your final goods, workflow, and efficiency can all be significantly improved with the correct software.

1. An intuitive user interface is one of the most important elements to search for. You may rapidly become up to speed with a layout that is clear and easy to understand, especially if you are new to CNC programming.

2. Compatibility with your CNC machine is an additional vital aspect. Make sure the program is compatible with the computer kinds and file formats you use.

3. Search for software that has sophisticated simulation features. You can save time and materials by catching problems before cutting when you can simulate your toolpaths.

4. Options for customization are also beneficial. Seek out software that lets you change things like tool routes, spindle speed, and feed rate.

In order to keep you up to date with new features and problem patches, good CNC software should also offer frequent updates and support.

Comparison of Popular CNC Programming Software

Each software has its strengths, and the best choice will depend on your specific needs and level of expertise. Here’s a comparison of some popular CNC programming software based on features, ease of use, and cost.

| Software | Best For | Features | Cost |

|---|---|---|---|

| Carbide Create | Beginners | Basic 2D design, simple toolpaths | Free |

| Easel | Hobbyists | Web-based, drag-and-drop design | Free/Paid Options |

| Fusion 360 | Intermediate/Hobbyists | 3D modeling, CAM, simulation | Free (Personal Use) |

| Mastercam | Professionals | Advanced toolpaths, multi-axis | Paid (Subscription) |

| SolidCAM | SolidWorks Users | iMachining, integrated workflow | Paid (Subscription) |

| PowerMill | Industrial Applications | High-speed, 5-axis machining | Paid (Subscription) |

How to Choose the Right CNC Programming Software for Your Needs?

Choosing the best CNC programming software can be difficult, but these pointers should help. Selecting the appropriate device is essential for a positive outcome.

· Professionals will benefit from sophisticated functionality, while beginners should search for software with clear interfaces and guided instructions.

· Make sure the program you select is compatible with both the kinds of projects you intend to work on and your particular CNC machine.

· Select options based on your priorities, such as multi-axis support, toolpath optimization, or 2D vs. 3D modeling.

· While free software is often a valuable resource for learning, commercial versions of the program frequently offer more sophisticated features and superior support.

· Seek for software with a robust user community, tutorials, and excellent customer service for assistance when needed.

You can select software that best suits your needs by reducing the number of possibilities available to you by considering these aspects.

Tips for Getting Started with CNC Programming Software

Using CNC programming software for the first time can be scary, especially if you have never used CNC machining. Getting familiar with the software's user interface is the ideal place to start. Examine the menus, toolbars, and main features one by one. Most software offers tutorials or initial instructions to help you learn how to use its fundamental functions. Use these materials; they are designed to accelerate your learning.

· Take little steps at first, working on easy assignments. This will let you to generate G-Code, set up toolpaths, and create designs without feeling overly pressed for time. You can progressively advance to more difficult projects as your confidence grows.

· Utilizing the simulation feature to its fullest is another excellent idea. Prior to machining, running simulations enables you to see possible problems and gauge how well your design will work in practice.

· Keep the handbook for your machine close at reach. Errors can be avoided by being aware of how your particular CNC machine handles commands from the software.

· Participating in online communities or forums pertaining to CNC programming is also beneficial. There are plenty of knowledgeable individuals on these platforms who can respond to your queries, provide insightful advise, and reveal information not found in manuals.

Frequently Asked Questions

What is the easiest CNC programming software for beginners?

Ans. Easel and Carbide Create are often recommended for beginners due to their simple interfaces and guided design processes.

Can I use free CNC programming software for professional work?

Ans. While free software can handle basic tasks, professional work usually requires advanced features found in paid versions like Mastercam or SolidCAM.

Is Fusion 360 free for commercial use?

Ans. Fusion 360 offers a free license for personal, non-commercial use. Commercial users need to subscribe to a paid version.

What is the difference between CAD and CAM in CNC programming?

Ans. CAD (Computer-Aided Design) focuses on creating the design, while CAM (Computer-Aided Manufacturing) focuses on creating the toolpaths and G-Code needed for machining.

How can I improve my CNC programming skills?

Ans. Practice regularly, explore tutorials, join forums, and experiment with different software features to enhance your programming skills.

Conclusion

Selecting the appropriate CNC programming software is essential to streamlining your machining process and producing results that are up to par. There is software to fit every requirement and ability level, from easy-to-use solutions like Carbide Create and Easel to complex tools like Mastercam and PowerMill. The effort you spend choosing the best software will pay you in increased productivity and efficiency, regardless matter whether you are a professional seeking accuracy or a hobbyist seeking to learn.

Understanding the benefits and drawbacks of various CNC programming tools will help you make an informed choice that complements the capabilities of the machine and your objectives. Spend some time analyzing your requirements, experimenting with various solutions, and selecting a solution that will enable you to advance and succeed in your CNC initiatives.