1. Increased Productivity

CNC router machines don't take breaks, don't go out to lunch, never have sick days and don't need sleep. The only time they need to take off from work is for regular scheduled preventative maintenance. This provides for greater productivity, another factor in keeping per piece prices down.

2. Consistency

CNC router machines are able to maintain a higher level of manufacturing consistency than human operators. The machines are never tired, distracted or in a bad mood. This helps improve the quality of part production and reduces waste. This is also valuable in cases where tight dimensional tolerances need to be maintained.

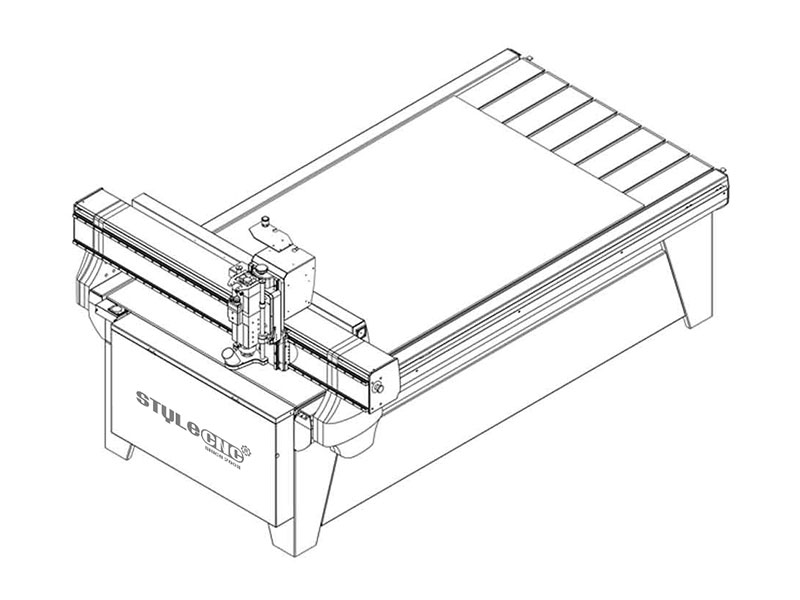

3. Agility

CNC machines can accept design changes quickly and easily, allowing the engineering team to update parts and designs, without the need to modify expensive tooling. This agility also allows the machine to switch rapidly from manufacturing one part to another, without the time expenditure in tooling setup.

4. Lower Labor Costs

Since the machine works on Its own, it doesn't require skilled machinists for operators. A person with a lower skill level can actually supervise several machines, further reducing labor costs.

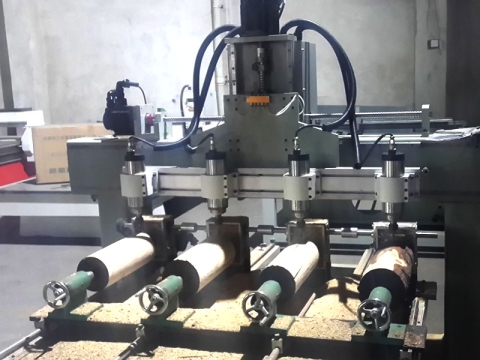

5. Adaptability to Complex Designs

One of the hardest things to machine is complex curves. However, for a CNC router machine, this is just another day at the office. In fact, CNC router machines are often the only way to accurately and consistently machine around compound curves (curved in two different axis at the same time). Even with these complex designs, CNC router machines can still maintain tight tolerance and extreme consistency.

6. Reduced Scrap Rate

Since parts can be machined consecutively on a CNC router machine, there is little to no wasted material in the part "blank". In many cases, blanks are not needed, as the parts can be continually cut directly from bar stock. In addition, the consistency of the manufacturing process virtually eliminates parts being scrapped for not passing Quality Assurance inspections.