This 6x12 large CNC table is as good as it gets for industrial manufacturers at an affordable price point. Reasonably solid & accurate. In addition, the software is user-friendly for beginners and machinists.

Industrial 6x12 CNC Router for Aluminum Composite Panels

Industrial 6x12 CNC router for aluminum composite panels (ACP) is a flatbed cutting machine for aluminum plate, aluminum sheet, aluminum parts with high speed & accuracy. Now the best aluminum CNC machine for sale at affordable price.

- Brand - STYLECNC

- Model - STM2040-R1

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 6' x 12' (72" x 144", 2000mm x 4000mm)

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

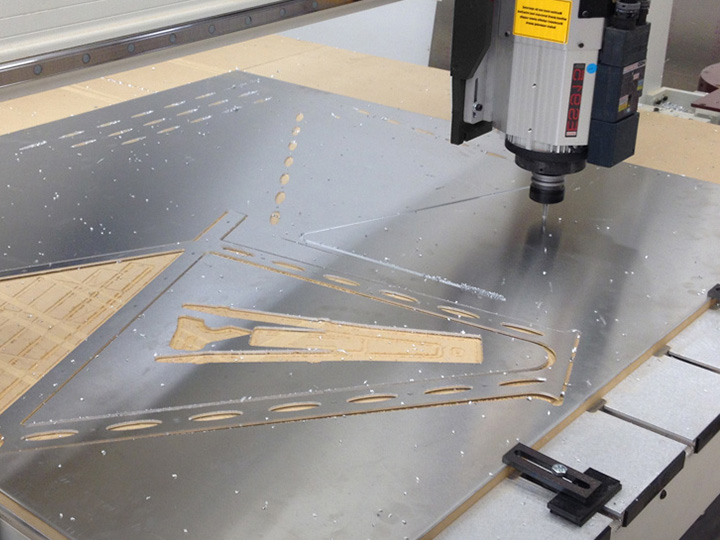

The industrial 6x12 CNC Router is a reliable instrument for precisely cutting, shaping, and sculpting aluminum composite panels (ACP). It is perfect for enterprises that are involved in interior design, architectural cladding, and sign-making because of its broad work area and ability to handle demanding jobs. These devices save material waste and labor expenses by providing automated and effective panel processing.

Aluminum composite panels are popular due to their strength, lightweight design, and versatility; nonetheless, precise cutting equipment are required while working with them. The smooth operation and flawless edges of the 6x12 CNC router, even on elaborate designs, simplify difficult tasks. For big projects, productivity is increased by huge sheet sizes and quick processing speeds.

A 6x12 CNC router can significantly boost productivity in any type of industry, including manufacturing, signage, and construction. Businesses can easily fulfill manufacturing timelines, minimize errors, and create custom designs because of their adaptability.

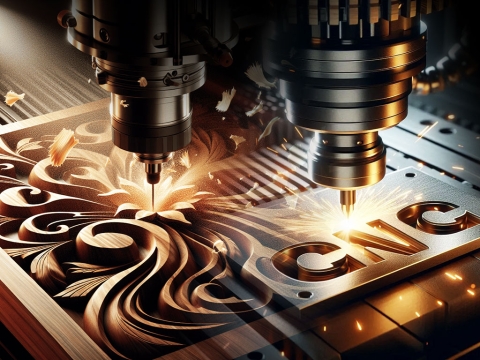

What is an Industrial 6x12 CNC Router for Aluminum Composite Panels?

An industrial 6x12 CNC router is a computer-controlled cutting machine that uses precise tool paths to shape, cut, or engrave aluminum composite panels. The working area measures six feet by twelve feet, and this is referred to as "6x12." This allows it to process huge ACP sheets in a single run. Its precision-controlled motors and high-speed spindles ensure burr-free edges on even the most delicate designs.

To increase productivity, these routers come with vacuum tables, spindles, and automated tool changers. They employ software to translate design files, like G-code, into machine motions, which makes accurate cuts devoid of human mistakes possible. Various cutting tools that are optimized for aluminum and composite materials are frequently installed on the machines.

This machine is very good at milling, routing, and engraving. Operators can quickly change materials or cut depths with automated control without having to halt production. Dust collection systems and other elements also guarantee a tidy workspace and little downtime.

The 6x12 CNC router is popular among manufacturers, construction companies, and sign-making businesses because it is made to endure the harsh conditions of an industrial setting. It is a vital tool for tasks requiring reliable, high-quality results due to its accuracy, speed, and adaptability.

Features of Industrial 6x12 CNC Router for Aluminum

1. Big size CNC router for aluminum composite panels (ACP) cutting is designed with high strength double driving motors of Y axis, which have a more reasonable design, higher processing speed, easy-operated maintenance, and low fault rate.

2. High-power air cooling spindle with higher strength and higher efficiency.

3. Configured with HIWIN linear rail from Taiwan, which is more stable, precise, and lower noise.

4. Z axis adopts top brand ball screw with industrial level, which can position accurately to make processing effects more perfect.

5. Helical rack transmission for X, and Y axis.

6. DSP Control System: USB interface, no need to connect with PC, easy to operate and convenient.

7. Vacuum table with great absorption strength, and high efficiency for mass production.

8. Energy-saving vacuum absorption and dust collectors can protect the environment.

9. Softwares have good compatibility. The CNC router machine for aluminum can be compatible with various CAD/CAM design software such as TYPE3, Artcam, JD, UG, MasterCAM, and PowerMill.

Technical Parameters of Industrial 6x12 CNC Router for Aluminum

| Brand | STYLECNC |

| Model | STM2040-R1 |

| Working Table | T Slot Table |

| Table size | 2000mmx4000mmx200mm |

| Spindle | 5.5KW Air Cooling Spindle (6KW Air Cooling Spindle or HSD Spindle for Option) |

| Max Travelling Speed | 35m/min |

| Max Working Speed | 30m/min |

| Spindle Rotation Speed | 0-24,000rpm |

| Operating system | DSP Control System (NC Studio 53C System for Option) |

| Command | G Code |

| Driver&Motor | Stepper Motor and Leadshine Driver System |

| Transmission | Z axis: Germany Ball Screw X,Y axis: Helical Gear Transmission |

| Guide Rail | Taiwan HIWIN Guide Rail |

| Dust Collecting System | 3KW dust collect(Option) |

| Working Voltage | 220V / 380v, 50hz, 3ph |

| Weight | 1800KG |

| Price Range | $5,780.00 - $11,000.00 |

Applications of 6x12 Industrial CNC Router for Aluminum

The 6x12 CNC router is used across a range of industries where aluminum composite panels (ACP) are integral. Here are some of its most common applications.

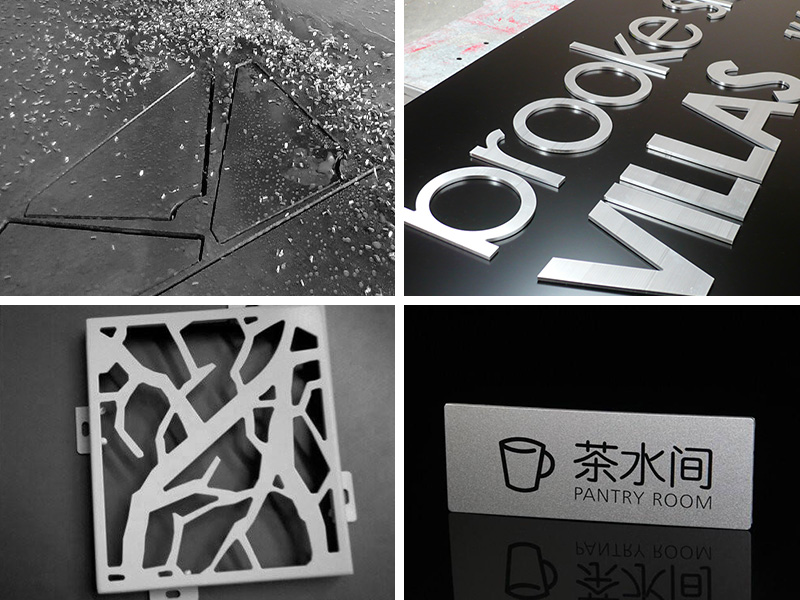

Architectural cladding and facades

Construction companies use CNC routers to cut aluminum panels for building exteriors and cladding. These panels provide an aesthetic, protective layer to walls, making the structures visually appealing and weather-resistant. The machine can cut intricate shapes or patterns, allowing for custom designs and architectural creativity.

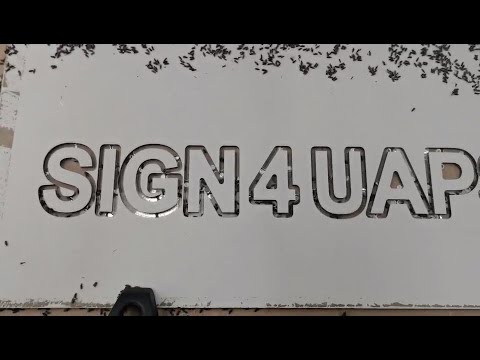

Signage and advertising industry

In the advertising world, ACP is a popular material for outdoor signs, billboards, and display boards. A 6x12 CNC router helps create crisp, precise letters and logos that are durable and resistant to weather conditions. Businesses rely on the router’s ability to handle bulk sign production while maintaining consistent quality.

Interior design and furniture

ACP is also used in interior design projects, such as wall panels, ceilings, and furniture components. With the CNC router, designers can achieve sleek and modern looks with perfectly cut edges. It enables precise routing for custom panel designs used in decorative partitions and cabinetry.

Transport and automotive industry

Lightweight and corrosion-resistant, aluminum composite panels are sometimes used in vehicle interiors and exteriors. The 6x12 CNC router helps manufacturers produce custom vehicle wraps, instrument panels, and interior components with precision and speed.

Mold making and prototyping

CNC routers are also useful in mold-making and rapid prototyping. The machine allows businesses to produce accurate molds or models from ACP sheets, which are commonly used in product development and testing phases.

Details of 6x12 Industrial CNC Router for Aluminum

5.5KW Air Cooling Spindle of CNC Router for Aluminum.

Industrial 6x12 CNC router for Aluminum in factory.

Industrial Aluminum CNC Router control box.

Industrial 6x12 CNC Router for Aluminum Projects

Benefits of Using a 6x12 CNC Router for Aluminum Composite Panels

Investing in a 6x12 CNC router offers several key advantages for businesses working with aluminum composite panels.

• High precision and accuracy: CNC routers use advanced software and automated control systems to ensure that every cut is accurate to the design specifications. This precision reduces waste and ensures that even the most complex shapes are cut perfectly, saving time and material costs.

• Large-scale production capability: With a working area of 6 feet by 12 feet, this CNC router can handle large ACP sheets in a single pass. This capability is crucial for businesses that deal with bulk orders or large-format signage, ensuring fast and efficient production without interruptions.

• Time and labor efficiency: The automated nature of the 6x12 CNC router eliminates the need for manual cutting, speeding up the production process. Operators can focus on design and quality control while the machine handles the repetitive tasks, reducing the need for extensive labor.

• Versatility for multiple applications: While primarily designed for ACP processing, the machine can also cut, engrave, and route other materials such as wood, plastic, and acrylic. This versatility makes it an excellent investment for businesses that work with a variety of materials.

• Reduced error and consistency: CNC routers provide consistent results with minimal human error. Once the design is uploaded, the machine performs the task the same way every time, ensuring uniform output across multiple projects.

• Cost savings in the long run: While the initial investment in a 6x12 CNC router may seem high, the long-term savings from reduced labor costs, material waste, and faster production outweigh the upfront costs.

How to Maintain a 6x12 CNC Router for Long-Term Performance

Proper maintenance is the key to keeping your 6x12 CNC router running smoothly for years. A well-maintained machine ensures consistent performance, reduces downtime, and prevents costly repairs. Follow these essential tips to extend the lifespan of your CNC router and keep it operating at its best.

Clean the Machine’s Operating Parts and Surface

Regular cleaning removes dust, debris, and metal particles that can build up over time. A clean workspace ensures smooth movements and prevents components from getting clogged or stuck. Neglecting cleaning can impact accuracy and reduce the machine's efficiency.

Lubricate Rails, Bearings, and Lead Screws

Frequent lubrication minimizes friction between moving parts, preventing wear and tear. Smooth operation ensures the machine runs without jerks or interruptions during work. Use the recommended lubricant to protect components and prolong their lifespan.

Inspect and Calibrate the Spindle

Regular inspection helps you detect unusual noises or signs of overheating early. Calibrating the spindle ensures precise cutting depth and avoids inconsistencies in performance. Neglecting the spindle can lead to imprecise cuts and impact product quality.

Check Wiring and Electrical Components

Tight and secure electrical connections reduce the risk of malfunctions or sudden shutdowns. Loose connections can cause operational errors or damage delicate machine parts. Make it a habit to inspect wiring to avoid unnecessary downtime or repairs.

Update Firmware and Software

Software updates from manufacturers often include performance enhancements and bug fixes. Regular updates ensure smooth and efficient operation without unexpected issues. Outdated software can lead to compatibility issues and affect machine functionality.

Monitor Cooling Systems

Cooling systems are essential when cutting aluminum, which generates heat during processing. Proper cooling prevents overheating that can damage components or reduce precision. Check the cooling system regularly to ensure it is functioning correctly for optimal performance.

Buzz Killingsworth

Jagan Mishra

Great STM2040-R1, it's excellent. I bought from STYLECNC a few months ago. I love this kit. Has been cutting well on Aluminum composite panel and plywood sheet. The computer program makes me enjoy the fun of CNC machining all the time.