CNC Router Machine Cutting Quality

CNC router machines allow for precise control of all the variables that affect how the tool performs its cut into the material being machined. this translates into consistent high quality, smooth, even cuts.

Frame Rigidity

It is generally believed that better cut quality is achieved by using a more rigid and accurate machine. While rigidity of the frame and accuracy have major roles to play, other factors are very important in affecting cut quality, such as control features, acceleration and deceleration, tool holding, and part holding.

Mass alone will tend to compound machining errors since a heavy moving part carries more momentum and is harder to start and stop. Conversely, too light a frame will allow for more vibrations and limit the loads that can be applied.

Bear in mind that not one single feature of the machine will determine its quality but a combination of all of these features.

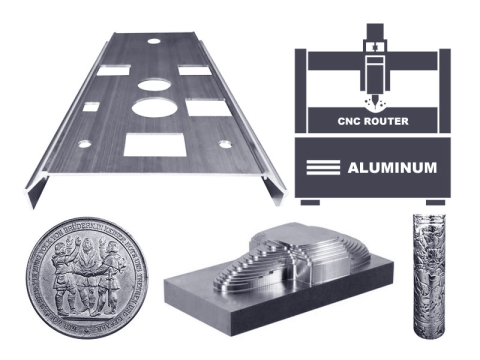

CNC Router Machine Cutting Accuracy

Accuracy is a simple CNC router machine characteristic to measure although simply comparing cut length with programmed length alone is not a good evaluation of accuracy.

Positioning Accuracy

Absolute positioning accuracy means the ability to reach a point in space within a certain tolerance. this measure can change greatly whether it is measured on a single or on multiple axes, or on whether or not there is a load applied to the cutter head. this measurement is also dependent on the position of the piece on the work table. different numbers can be obtained in different areas as ball screw compensation tables can be off or missing altogether.

Spatial accuracy is mostly dependent on encoder resolution. a high quality, properly adjusted servo system can normally position within plus or minus ten times the encoder resolution. therefore, a system with 0.0005" resolution can only be expected to achieve plus or minus 0.005" or 0.1 mm positioning accuracy.

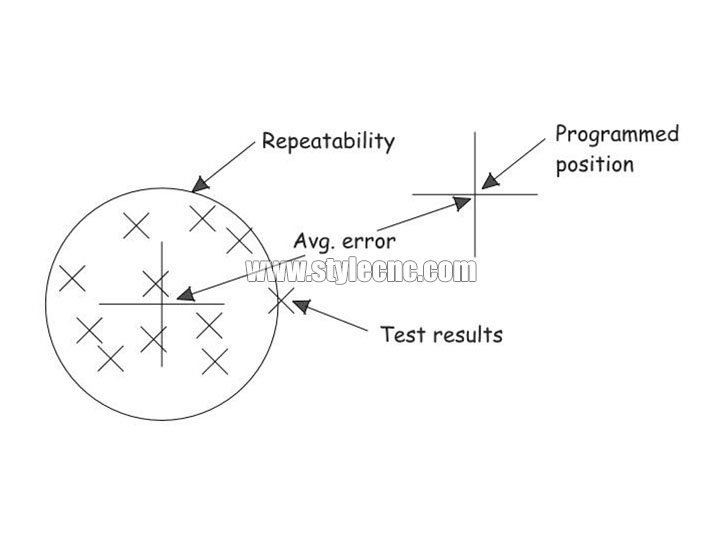

Repeatability

Repeatability is the ability to return to a point in space each time a program is executed. Just like absolute accuracy, repeatability can either be measured on a single axis or on multiple axes. on most systems, repeatability always outshines absolute positioning accuracy.

Predictability

This is important in the business of cutting parts using computer controlled equipment. you want the control portion of the machine to work the same way every time no matter what program is running. a good controller will calculate the tool path many steps ahead and alert you or decide on a different course of action when it finds problems.

In the early days of Point-to-Point machines, the computer told the head to move to a certain position in X-y. the drives executed this operation without consideration for the path that the tool would take.

On newer CNC router machines, the movement of the axes are coordinated with each other to obey a set of given rules. this gives them the ability to circle around fixtures and to ease the cutter in and out of a part for example. this is known as an interpolated path.