STYLECNC production of CNC router machine and other equipment, and strictly control the production process, strict quality control in the selection and fitting process, strict adherence to high-quality production process to ensure stable production of the CNC router machine, so that more domestic and international customer satisfaction.

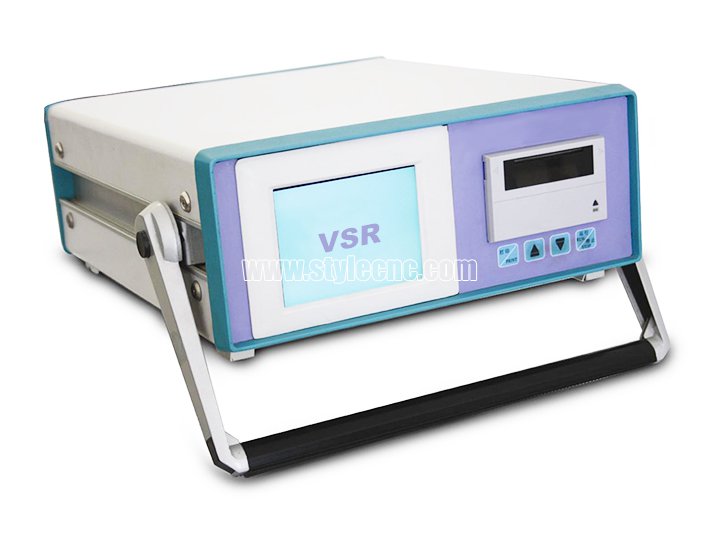

In the CNC router machine body treatment, we use VSR treatment process.

What is VSR?

Vibration technology known as vibration do to eliminate stress, also known in our country do VSR. It is a system of a motor having an eccentric weight mounted on the member, and an elastic member with a rubber pad and other objects supported by the controller to start the motor and adjust its speed, so that member is in a resonance state. After about 20 to 30 minutes of vibration treatment can achieve the purpose of adjustment of residual stress, generally accumulated vibration time should not exceed 40 minutes.

After aging treatment, the mechanical properties improved significantly.

Vibration member after processing the residual stress can be eliminated about 20% to 80% higher tensile stress zone is larger than the elimination of the low stress zone. It is possible to improve the use of strength and fatigue life, reducing stress corrosion. You can prevent or reduce the incidence of the heat treatment, welding and other processes caused by microscopic cracks. Can improve the ability of member resistance to deformation and stable precision components and improve the mechanical quality.

STYLECNC not only strictly control the quality of parts, parts of the production process is also very important. STYLECNC determined to provide first-class CNC router machine and other equipment for all customers.