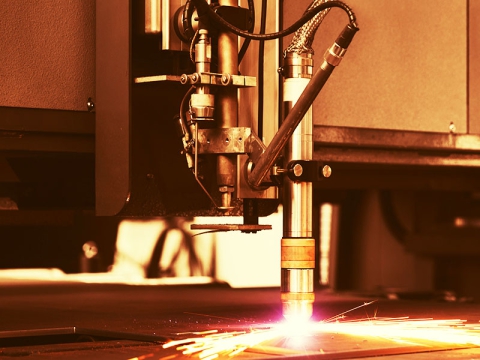

The workpiece can be cutting a variety of complex shape, and has high cutting speed, high efficiency, good cutting surface quality, cutting the workpiece size precision and the advantages of small thermal deformation. Cutting parts without machining can be directly carried out welding and application. But the CNC plasma cutting machine is used for plasma arc cutting, and it compared. Oxygen cutting still has some defects, mainly reflected in the cutting plane inclination is large, good finish without oxygen cutting. The main criterion for evaluating the quality of CNC plasma cutting: cutting surface inclination, cutting depth, seam grain slag etc.. A good cutting surface of the slope should be below 30, depth of cut lines should be below O.15mm, and less slag, easy to remove. Under the condition of stable voltage and current, affects the cutting quality factors in addition to the electrode, the nozzle itself quality, mainly there are two reasons: one is cutting nozzle height and stability; the second is the cutting speed and working pressure of matching.

Cutting nozzle height above the plate when the arc voltage height adjusting device to control, because of its dynamic positioning precision can reach + 0.013 Zelda, so can guarantee the cutting nozzle and the plate height remains unchanged, so the cutting surface tilt is small and uniform, and finish well. When to adjust the cutting nozzle from the height of the steel plate by hand when. Try to cut steel flat, to reduce the number of adjusting cutting torch. To ensure the torch cutting process stability. This paper uses the manual adjusting mode, will cut mouth height control plate in 6 ~ 8

Mm, through the experiment of cutting a series, expounds the cutting speed, working pressure (dirty) (P) and the relationship between cutting quality.

Analysis and summary of the best cutting parameters of different thickness steel plate in different power cut. In order to improve the cutting quality of the CNC plasma cutting machine.

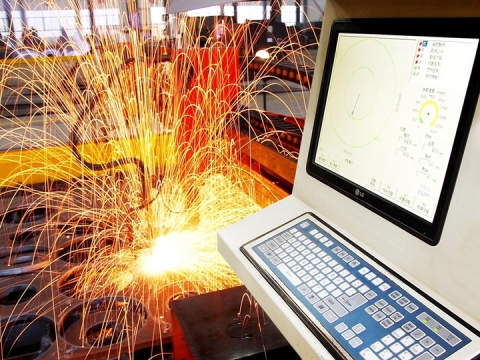

CNC plasma cutting machine is a kind of mechanical and electrical integration of advanced equipment for metal sheet cutting, and has been widely used in shipbuilding, machinery manufacturing and other industries. There are many factors affecting the cutting quality of CNC plasma cutting machine, in addition to the design parameters of the cutting machine, it is also related to the operation control, the cutting process and so on. In order to improve the cutting quality, we carried out a comprehensive cutting test, according to the test data analysis and finishing, obtained a CNC plasma cutting machine part of the best working parameters. Now described as follows:

CNC plasma cutting machine test methods

Test equipment for four different power air plasma cutting machine each one, each model of the electrode, the nozzle of the 6 sets. Four sets of air plasma cutting machine cutting torch, sequentially installed in the CNC cutting machine cutting trolley. Each type of air plasma cutting machine to be alone to complete the whole process of all the tests with different cutting speed, using different pressure, on the different thickness' A3 steel plate for cutting (cooling water). Cutting from low pressure to high pressure, from low speed to high speed. The air pressure is adjusted by the filter control valve, and the cutting speed is controlled by the numerical control cutting machine. Cutting parts for 100 x 100 mm square parts.

When the cutting speed is too high and the air pressure is too low, the cutting surface is large. This is because the speed is too fast, the arc column seriously backward, melting speed with no cutting part. So the small size parts cutting plane. Dimensions of the lower plane of the large, especially when cutting the rectangular shaped parts. In the slot at the bottom of the corner into circular arc instead of a right angle shape. If the cutting speed is too low, high pressure slag is serious, not easy to remove, poor roughness. If the appropriate cutting speed, working pressure is too high, the arc column stiffness and smooth degree of damage, cutting ability poor finish cutting. So, cutting the steel plates of different thickness, the need for a reasonable choice of different cutting power, cutting speed and working pressure, in order to get the best effect of cutting.

According to the test results of four different power models, the optimal cutting parameters of cutting different thickness steel plate cutting machine in different power. According to these data we in some manufacturers for the practical application of cutting, the effect is very good, the cutting quality is greatly improved.

We know that the influence factors of CNC plasma cutting machine cutting quality, except for a few of the parameters mentioned above, a variety of factors and the cutting process and cutting method, electrode nozzle quality etc.. But in the actual cutting process. As long as provided in accordance with the above optimal cutting parameters cutting, control the cutting speed, working pressure and torch height, you can meet the requirements of cutting quality. In cutting voltage, cutting current stable, electrode and nozzle life can be doubled