Alphacam Router is an easy-to-use CAD/CAM solution for manufacturers wanting fast, efficient toolpaths and the generation of reliable, machine ready CNC code.

The complete process...

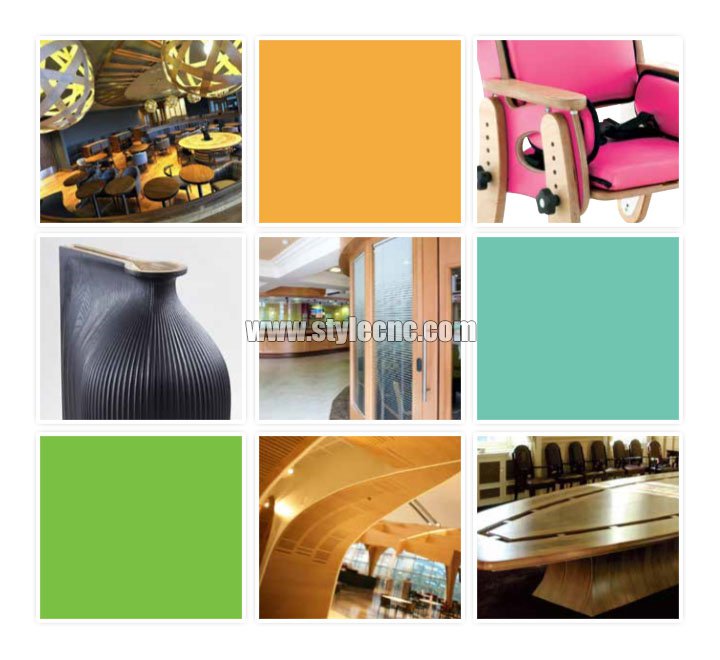

Alphacam is the total CAD/CAM solution for the woodworking industry.

Alphacam seamlessly integrates both 2D and multi-axis machining, providing an extensive list of cutting strategies which can be applied to any type of component. The emphasis behind Alphacam is to provide customers with productivity, reliability and flexibility. This can be found in all our modules which include Routing, Milling, and Turning.

Our strength is in providing world class innovative solutions that gives you the end-user software applications that are essential to the design and manufacture of your products.

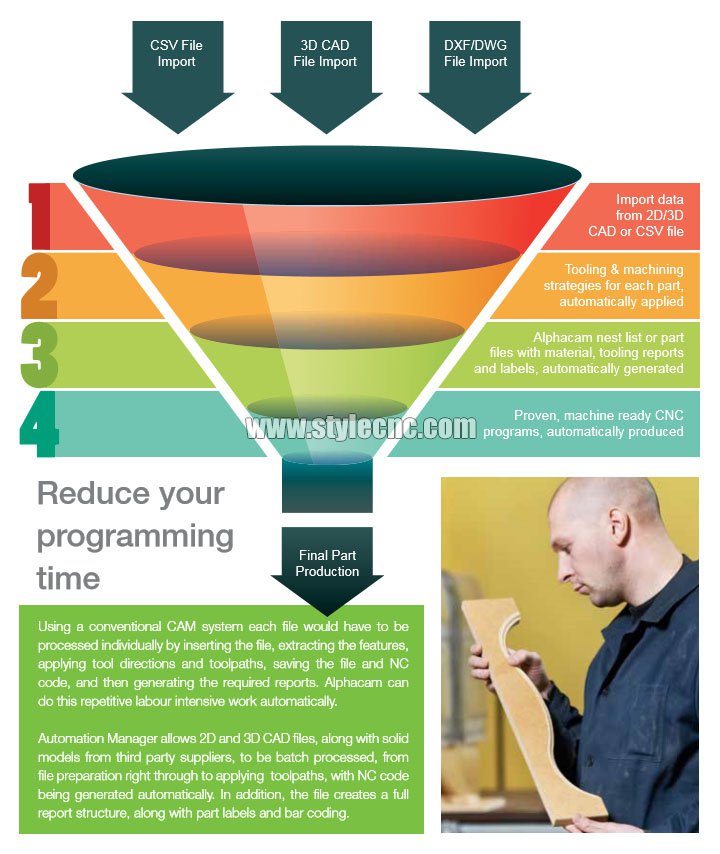

Automate with Alphacam

Communicate your engineering data directly from your CAD software to your CNC machinery.

Core Foundation

All Alphacam modules are built using one core foundation which includes geometry creation commands. Import options for DXF, DWG, IGES and a variety of solid model formats ensure compatibility with other CAD systems.

All modules have user-defined tool and material libraries controlling many of the important machining parameters such as tool direction, automatic lead in and lead out, corner cut options (straight, roll round or loop), G41/42 tool compensation and automatic calculation of speeds and feeds.

Nesting

Nested based manufacturing is made easy using Alphacam’s automatic nesting functionality. Parts can be selected directly from the screen or as a kit; their orientation fixed, if grain direction needs to be maintained or rotated to any angle. Nesting supports tool lead in/out, support tags for small parts, avoiding loss of table vacuum and multiple depth cuts, if an onion skin is required.

Routing

Ease-of-use is just one of the reasons that Alphacam is the industry standard and system of choice for programming CNC routers. Tooling and machining techniques unique to this industry are accommodated by Alphacam’s dedicated Router modules.

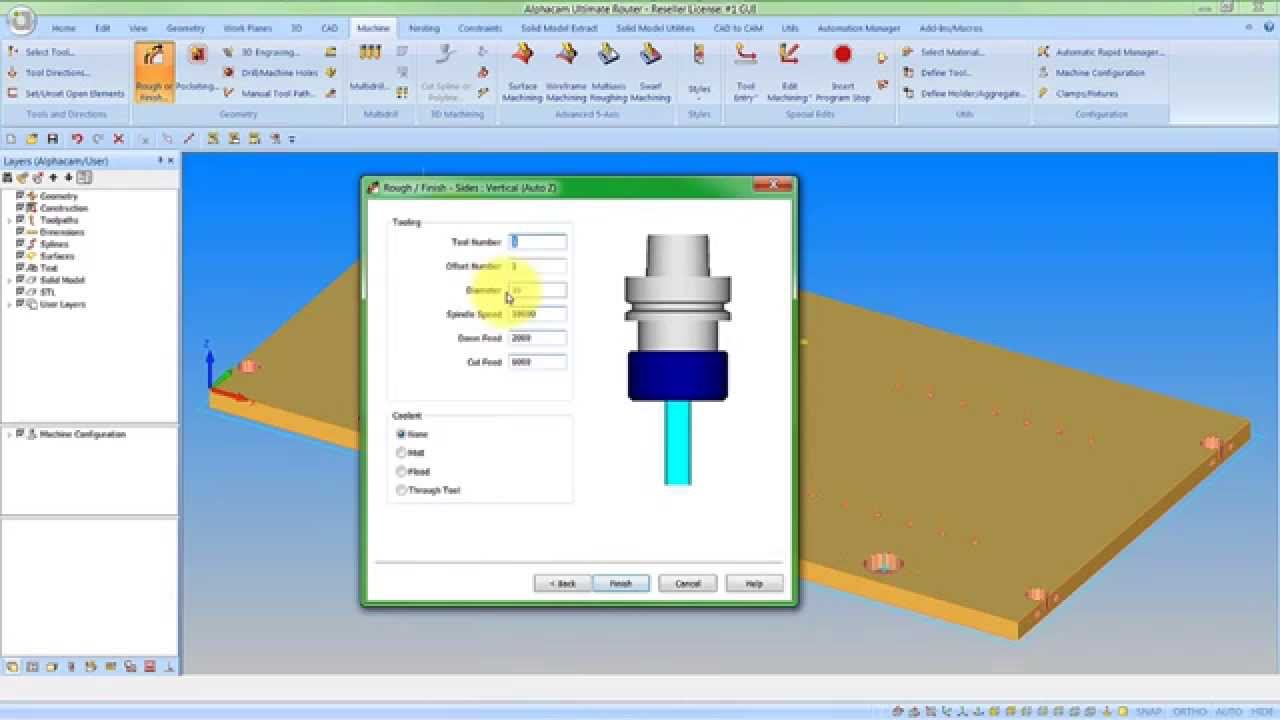

3D Routing

Multiple 3D rough and finish machining strategies of surfaces, STL models and other native CAD models are available within Alphacam. These strategies can be applied to any work plane, allowing for 3 plus 2 machining to be programmed using Alphacam on machines with 4 and 5-Axis rotary heads. Alphacam’s Ultimate module is capable of 4 and 5-Axis simultaneous machining of surfaces and 3D trim curves, often used for finishing chair backs.

Post Processors

It is essential to maintain maximum machinery efficiency to ensure optimal production throughput. Having an optimised link between Alphacam and your CNC machines is a key component in attaining this efficiency. Having developed post processors for virtually every machine control in use today, Alphacam has the knowledge and experience to fine tune your CNC output ensuring maximum yield and quality in the shortest possible time.

Alphacam’s powerful post-processing ability means that the advanced functionality of all CNC controllers is utilised, including plane rotation.

Horizontal Aggregates

Horizontal aggregates for hinge reliefs and lock mortices are easy to control.

Horizontal aggregates, available on nearly all CNC routers, for machining hinge reliefs and lock mortices for example, are easy to control using Alphacam. Standard operations can be created and saved and inserted on to work planes when required, saving programming time.

Multi-Axis Machining

Alphacam Supports Routers With Fully Interpolating 5-Axis Heads

Head mounted rotary axes on CNC routers can be programmed at any orientation. Aggregates with a programmable rotary axis and manual tilt are fully supported, as well as routers with fully interpolating 5-Axis heads. Safe rapid moves between planes are automatically controlled and verified using advanced solid simulation.

Dedicated Drilling

Unit Drilling paths can be optimised for any drill unit using Alphacam’s Multi-Drilling command. Holes are matched to the drill diameters and automatically machined, multiple drills are selected simultaneously when a standard 32mm pitch is matched.

3D Engraving

Artwork and text can be easily created and machined using powerful 3D engraving. This command contours geometries with a form tool, and on meeting a sharp corner automatically retracts the tool to produce a sharp corner, often referred to as embossing.

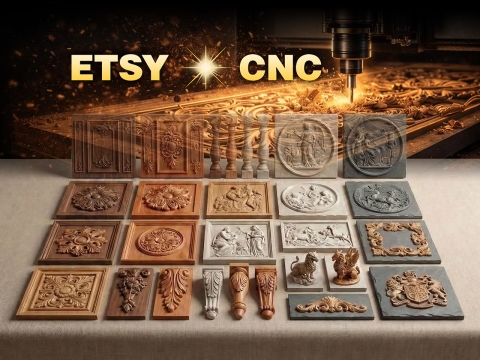

Alphacam Art

The easiest way to go from a 2D drawing or sketch to high quality 3D low relief and CNC toolpaths.

Alphacam Art, powered by Vectric’s Aspire technology is 3D relief modelling and machining software for CNC routing and engraving projects such as carving decorative ornate panels and doors, swept flourishes, custom millwork, architectural mouldings, dimensional signage, bespoke company logos, jewellery pieces, custom gifts and awards.

With Alphacam Art, users can quickly and easily convert 2D sketches, photographs, drawings and graphic designs into unique high quality 3D

carvings and designs. Alphacam Art has been developed to give users complete flexibility and control when designing 3D CNC projects.

Using a flexible component management logic, users can easily and interactively change the size, position, orientation and material properties of regions or individual components in a project at any time.

Software That Grows With You

Alphacam Essential - The ideal entry level product for basic 2D CNC work.

Alphacam Standard - The perfect product for shops and subcontractors.

Alphacam Advanced - Targeted at the manufacturer who works with complex, free-form patterns and tools.

Alphacam Ultimate - Adds support for full 4/5-Axis simultaneous machining for high specification joinery and furniture manufacturers.

Software & Support

Vero has a support network of engineers who understand your business through experience. We will guide you through the modules and recommend the most appropriate combination of software, training and services that suits your needs.