This laser cutter comes with all the features I would expect. CNC controller is intuitive and easy to use, with all settings visible at a glance. 2000 watt fiber laser is powerful enough to handle all my metal cuts with ease, smooth and clean without burrs. Impressively stable performance, with a full day of continuous cutting without any issues. One thing I have to say, if your budget allows, go for a closed enclosure, after all, the open bed is not a 100% safe option for laser guys. Overall, this is a great buy for the money, and STYLECNC is a reputable brand with dependable options.

2026 Top Rated Fiber Laser Cutting Machine for Sale - 2000W

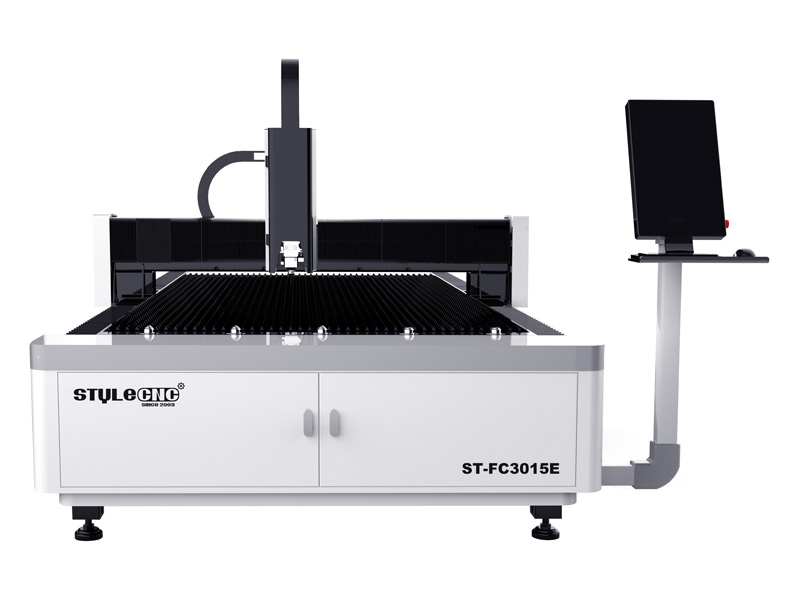

The top-rated fiber laser cutting machine is designed for sheet metal fabrication of steel, titanium, aluminum, brass, copper, alloy, gold, silver, and iron with power options of 1500W, 2000W, and 3000W. The ST-FC3015E blends cutting-edge technology with low costs for small business owners looking to improve their productivity, as well as hobbyists eager to try new things with metalworking. Now the affordable fiber laser cutter for sale at cost price with the best and professional laser metal cutting service and support.

- Brand - STYLECNC

- Model - ST-FC3015E

- Maker - Jinan Style Machinery Co., Ltd.

- Sizing - 5' x 10' (60" x 120", 1500mm x 3000mm)

- Category - Fiber Laser Cutting Machine

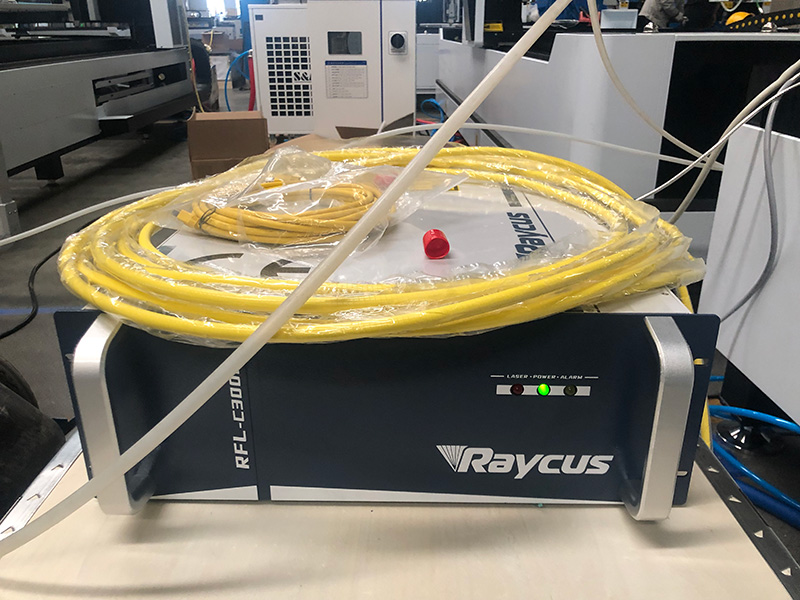

- Laser Source - RECI, Raycus, IPG, MAX

- Power Option - 1500W, 2000W, 3000W

- 180 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

This top-rated laser cutter blends cutting-edge technology with low costs to provide a solution that changes the way businesses and hobbyists work with metal. With power options from 1500W to 3000W, the ST-FC3015E provides great performance thanks to its powerful laser source from the world's leading manufacturer such as RECI, Raycus, IPG, or MAX. It's poweful enough to cut through sheet metals such as steel, titanium, aluminum, brass, copper, alloy, gold, silver, and iron to create high-precision and high-quality metal projects at high speeds.

Even though it's affordable, the ST-FC3015E doesn't skimp on features or quality. The ST-FC3015E comes with a high-quality laser cutting head and a high-speed Delta Servo Motor from Taiwan, enabling it to create precise cuts and perform consistently, so you can be sure that your projects will meet the greatest standards of quality.

The ST-FC3015E also features high-tech components such as an automatic oil cleaning system, an iPad-style screen with an Au3tech control system, as well as buttons that are easy to use so that it works smoothly. Its versatile design lets you cut sheet metals as well as shape metal tubes with an optional rotary attachment, giving you the most options for all of your manufacturing needs.

The ST-FC3015E changes everything for those who want to be more productive without spending a lot of money. The ST-FC3015E is a great choice for small business owners looking to improve their productivity, as well as hobbyists eager to try new things with metalworking. In conclusion, with STYLECNC's ST-FC3015E, you can easily create precision metal cuts at a low cost.

What is Fiber Laser Cutting Machine?

Fiber laser cutting machine is an automated CNC laser metal cutting equipment used to create precise shapes, contours, lines, and holes on metal sheets, tubes, and profiles. The features of high quality, high precision, high speed, and high efficiency allow it to become your best metal fabriction partner in modern industrial manufacturing.

This top-of-the-line fiber laser cutting machine comes with multiple laser power options (1500W, 2000W, 3000W) to cut through sheet metals of varying thicknesses, including stainless steel, carbon steel, mild steel, galvanized steel, tool steel, aluminum, titanium, copper, brass, iron, silver, and gold, making it an ideal metal cutting tool for both beginners and professionals thanks to its user-friendly CNC controller and powerful cutting capabilities. In addition, you can find more options from laser metal cutting machines.

How Does A Fiber Laser Cutting Machine Work?

The laser emitted by the fiber laser generator is focused into a high-power density laser beam through the optical path system. The beam irradiates the surface of the workpiece, causing the workpiece to reach the melting point or boiling point, and at the same time, the high-pressure auxiliary gas coaxial with the beam blows away the molten or vaporized material. As the CNC controller with CAM software instructs the beam to move relative to the workpiece, a slit is eventually created on the metal material, thereby achieving the purpose of cutting.

Technical Parameters

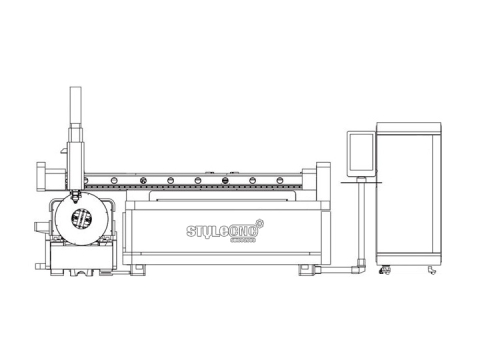

| Model | ST-FC3015E |

| Brand | STYLECNC |

| Working Area | 1500mm*3000mm |

| Max Cutting Speed | 40m/min |

| Laser Power | 1500W (2000W, 3000W for Option) |

| Max Acceleration | 0.6G |

| Repeated Positioning Accuracy | 0.02mm |

| Driving Way | Servo motor |

| Transmission Way | Y-axis gear rack double driver, X-axis ball screw |

| Power Requirements | 380V/50HZ/3P (220V Avaliable) |

| Machine Weight | 1600kg |

| Price Range | $13,000.00 - $16,000.00 |

Applications

Applied materials

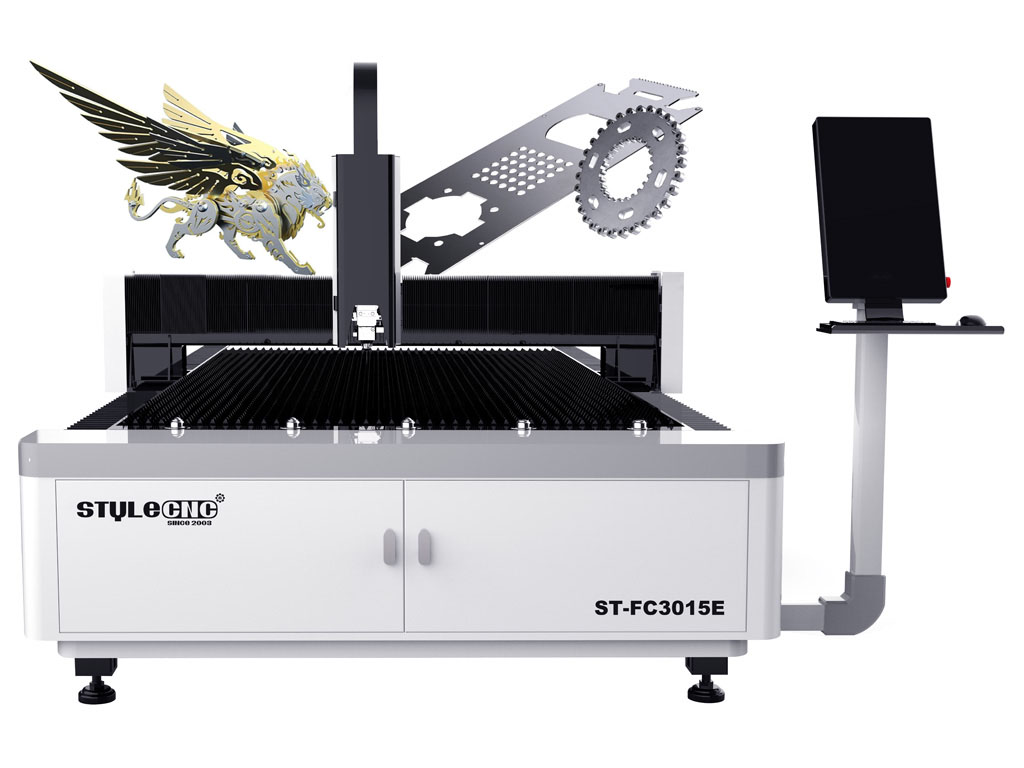

Fiber lasers are typically used for cutting stainless steel, carbon steel, electrical steel, galvanized steel, aluminum zinc plate, aluminum, aluminum alloy, titanium alloy, copper, brass, iron and other metal materials.

Applied Industries

Fiber lasers are mostly used in sheet metal fabrication, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts, arts and crafts, tool processing, adornment, advertising, metal foreign processing, and more metal fabrication industries.

Features

• Excellent beam quality - Smaller focus diameter and higher work efficiency, as well higher cutting quality.

• High cutting speed - More than 40m/min.

• Stable running - Adopting the top brand laser source with stable performance, and the service life span can reach 100,000 hours.

• High efficiency for photoelectric conversion - Compare with CO2 lasers, fiber lasers have three times photoelectric conversion efficiency.

• Low cost and low maintenance - Save energy and protect environment.

• Easy to use - Fiber line transmission without adjustment of optical path.

• Super flexible optical effects - Compact design and easy to flexible manufacturing requirements.

Details

Factory Tour.

Au3tech Laser Cutting Head.

3000W Raycus Laser Source, 2000W and 1500W for option.

Servo Motor.

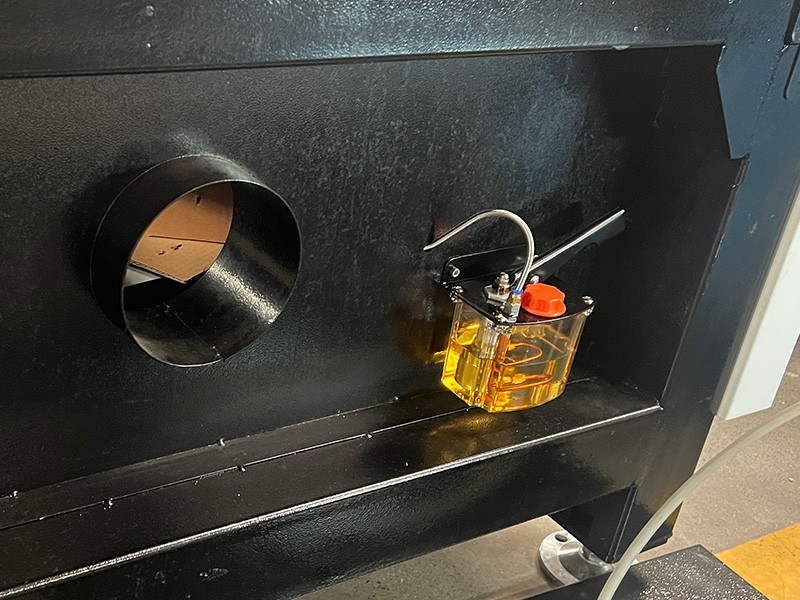

Automatic Oil Lubrication System: Keep the rails in good condition.

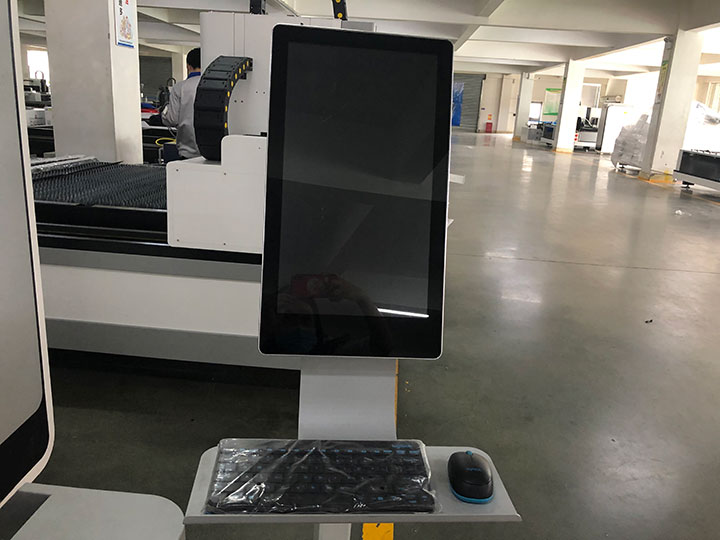

Ipad design screen with Au3tech control system.

Controlling Buttons - Easy to operate.

Multi-Purpose Fiber Laser Cutter for Sheet Metal and Metal Tube/Pipe

Machine Production at STYLECNC

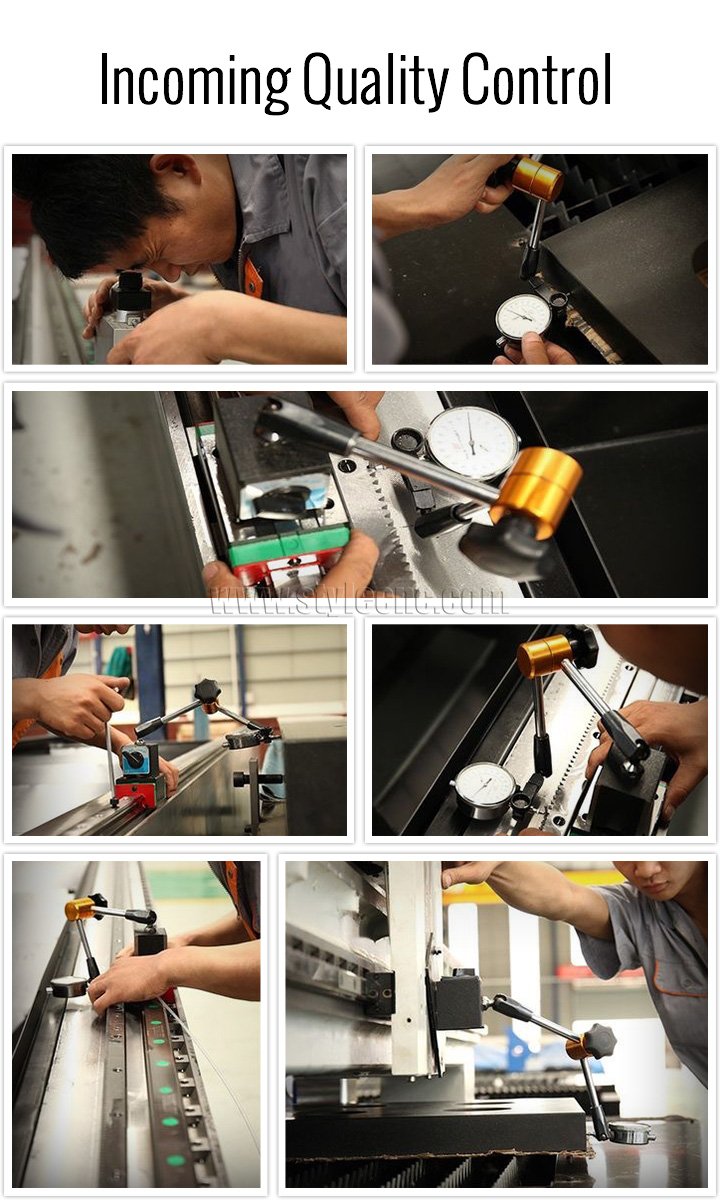

Incoming Quality Control

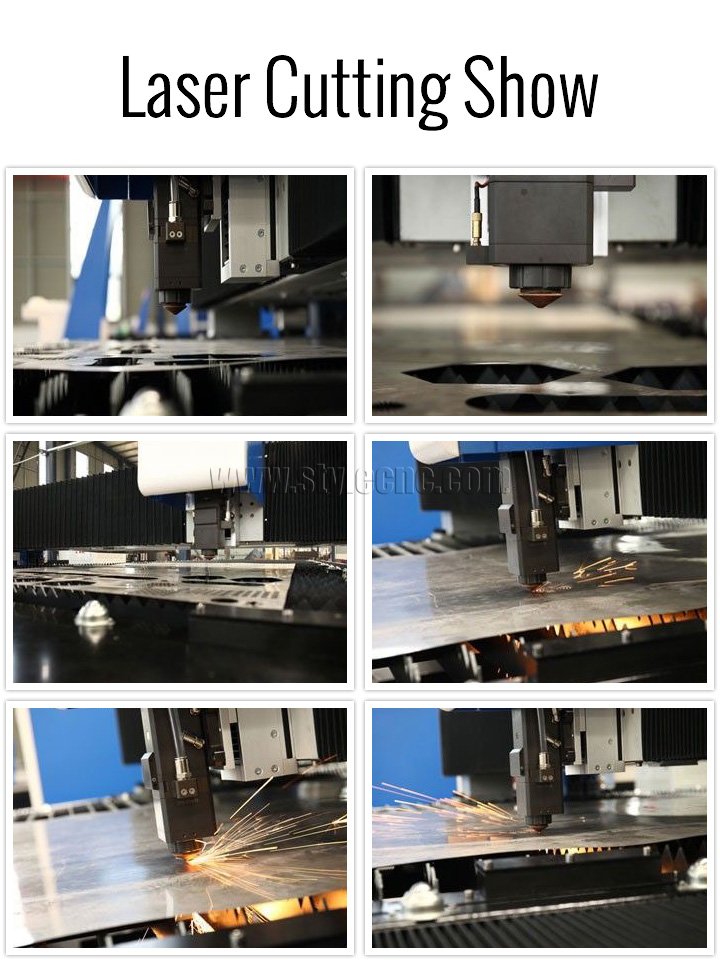

Cutting Process Show

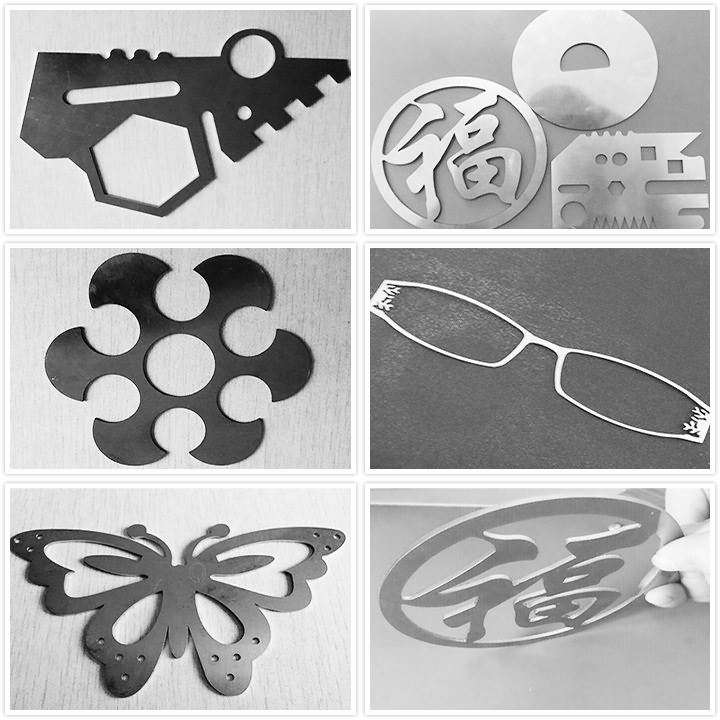

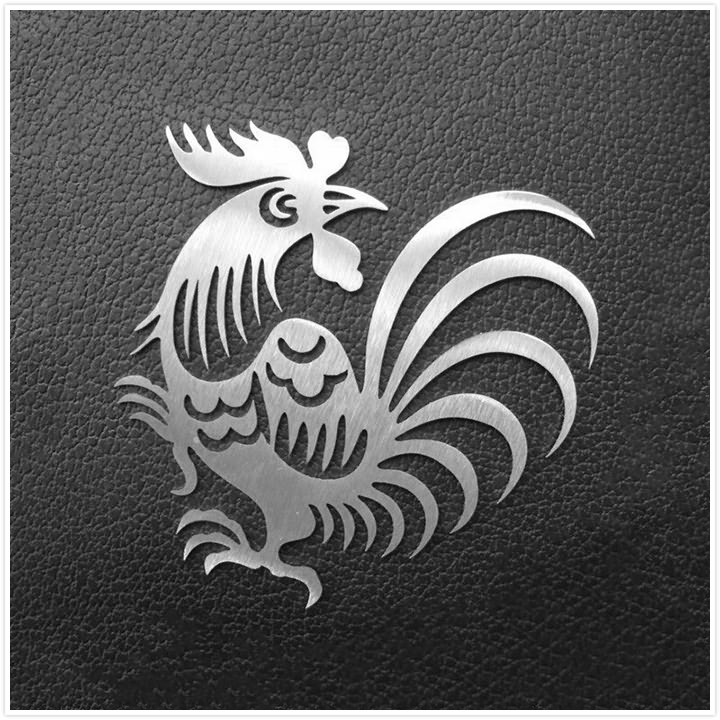

Fiber Laser Cutting Metal Projects

Package

• Strong water resit bottom in plywood.

• Laser source (separated plywood case) and spare parts on the laser bed.

• Corner protect by foam and fixed by protective film.

• All covered by strong and hard protective film.

• Vacuum packing.

• Inside steel frame protector.

• Plywood packing and steel strip outside fixed the box.

• Finishing packing by normal container or frame container.

Pre-Sale Service

• Free Sample Cutting Service:

For free sample cutting/testing, please send us your CAD file (PLT, AI), we will do cutting in our factory and make video to show you the cutting process and result, or send samples to you to check the cutting quality.

• Progressing Solution Design:

According to customer’s product processing requirement, we can design the unique solution that supports higher manufacturing efficiency and better processing quality for customer.

• Customized Machine Design:

According to customer's application, we may revise our machine according to customer's convenience and high production efficiency.

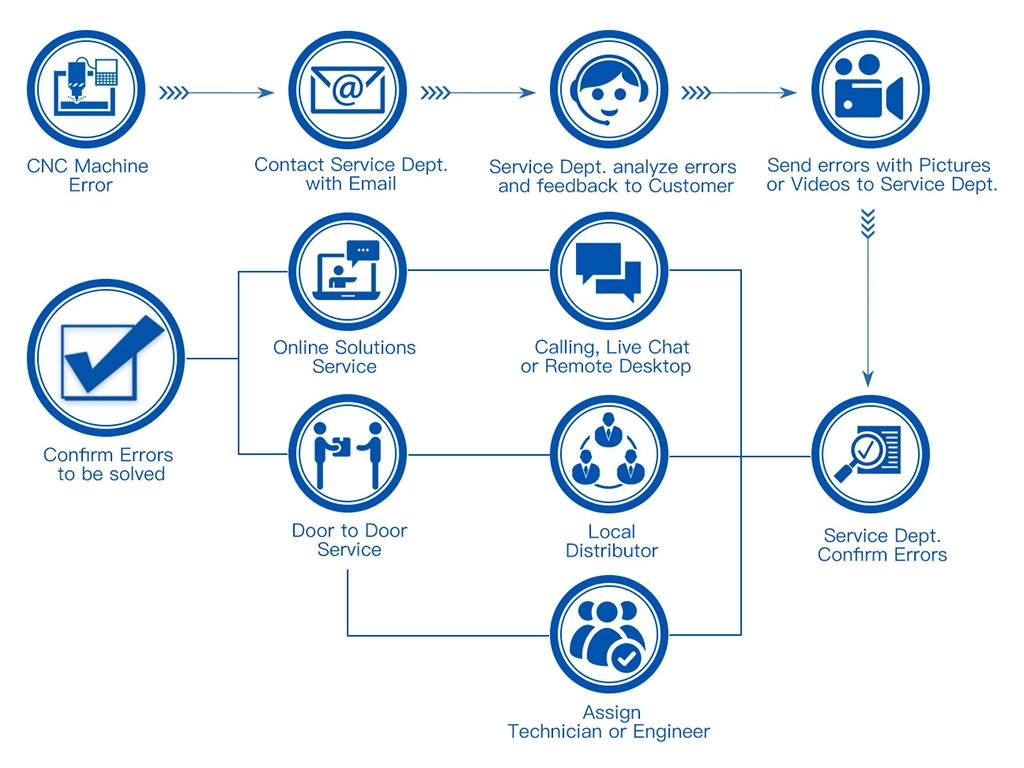

After-Sale Service

• As a professional CNC laser manufacturer and supplier, STYLECNC will supply the fiber laser machines with training video and user's manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote, such as TeamViewer, E-mail, Telephone, Mobile, Whatsapp, Skype, 24/7 online chat, and so on, when you meet some problems of installation, operation or adjusting.

• You can come to our factory for training. We will offer professional guidance, direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools and testing facility. Training Time: 3~5 days.

• Our engineer will do a door-to-door instruction training service at your local site. We need your help to deal with the visa formality, prepaid traveling expenses and accommodation to us during the business trip and service period before their dispatch.

Warranty

As the world's most popular CNC laser cutter brand in the world, STYLECNC promise:

• The entire machine comes with 1-year limited warranty (excluding consumable parts).

• Long life-time maintenance, after-sale department will offer 24/7 English online support.

• Except the damage artificially, we are responsible for offering the fittings free of charge during warranty.

• After the warranty period expired, the buyer only need to pay the actual maintenance cost.

• Certificate support: CE, FDA, SGS.

FAQs

If you want to get a free quotation, please answer the questions as following and tell us by email, so that we can recommend the most suitable machine and quota the affordable price to you directly.

• Do you need to cut metal sheets & plates, metal pipes & tubes only or both?

• If you need to cut tubes, what is your tube length, diameter and max thickness?

• For cutting metal sheet, what is the max working area required?

• After processed, what the materials will be used for? (Applications)

• Which seaport is the nearest to you?

• Do you have any experience in the laser cutting?

• What is your online chat way? Such as Skype and WhatsApp.

• Are you an end user or reseller?

Cost & Pricing

You have to consider many things when finding out the actual cost of a fiber laser cutting machine, including both hardware and software, as well as after-sales service and support.

• Machine components.

• Laser powers.

• Controller software.

• Add-ons.

• Shipping cost.

• Tax rates.

• Customs.

• Service and technical support.

Overall, fiber laser cutters range in cost from $13,000 to $1,000,000, with power options ranging from 1500W to 60000W. Low-power fiber lasers (1500W, 2000W, 3000W) are budget friendly, with an average cost of around $15,800. However, you have to spend at least $25,000 on a mid-power laser (4000W, 6000W, 8000W), and high-power lasers (12000W to 60000W) start at a pricey $49,000.

Buying Guide

When you have an idea to buy an affordable fiber laser cutter within your budget, firstly, you should find a professional and guaranteed manufacturer and supplier with best service and support, do not just pay attention to the price, The most important thing is that this CNC laser machine can finish your job well with high quality, high speed and high precision, and when you have problems with the cutting system, the after-sale service or technical support department are able to follow up in time and solve your problems. As a professional CNC laser manufacturer with core technology and independent intellectual property rights, STYLECNC has been committed to the development and manufacture of laser machines over 10 years, which can provide perfect design, development, production, inspection, transportation, service and support. STYLECNC can be your best choice to buy a fiber laser cutting machine for metal.

Jopanovic

Robert Salazar

The manual is minimal but the CNC controller is easy to use and drives a laser beam to cut through 1/4 and 3/8 steel sheet with ease, and voila I'm here and there is the most cost effective metal laser cutter you can pick.

Adam Jones

Randal Savage

In the past years, I have only used plasma cutters. I wanted something fast with high precision. This fiber laser cutting machine fit the bill. I wired it up for 220v use. It performed as described and cut through 1/8 steel plate with no trouble. Super handy metal cutting tool for beginners, but the only regret is that the initial investment cost is higher for business starters.

Hans Thrun

I use this metal laser cutter to cut stainless steel sheet of 1/4in x 4ft x 8ft to make signs for my advertising business. So far so good. It is easy enough to work with, and cuts well, like a hot knife through butter. Just hope to continue to use for a long time in future.

The software came with the machine is easy to use for my business. With remote assistance from STYLECNC, the software installation and setup can be completed in 45 minutes. Excellent customer service and technical support.

Also, 1064nm fiber laser beam is dangerous to cause eye injury and hand burns, wear leather gloves and safety glasses when using this machine. Overall, take care.

I try to buy well made laser machines that are worth my money, this unit seems to qualify. No real complaints about this cutting tool. Great value. Would highly recommend it.

Charles Johnson

Prince Chadha

Before purchasing, I asked some quotations from Chinese suppliers, after research and comparison, finally I keep 3 companies in my mind, after visiting China, finally I choose STYLECNC as the supplier. Their factory is very professional.

After about 2 months, we get our laser cutter installed in workshop, with the detail user manual and videos, I operate it very well now.