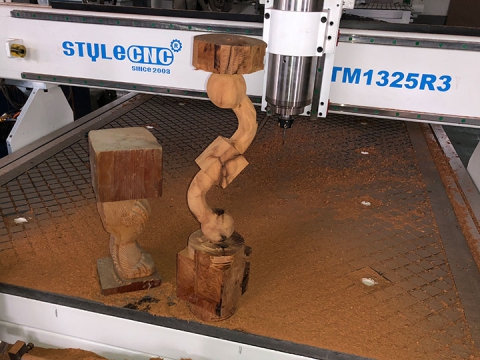

3D CNC Router for Wood Stairs

This is the most authoritative and professional video for 3D CNC router making wood stairs, review the working video, buy the best 3D CNC woodworking machine.

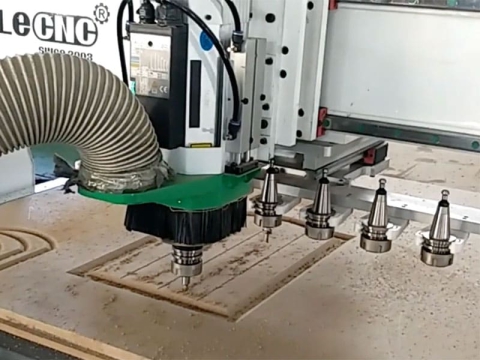

Looking for a CNC nesting router machine for custom closet door making and personalized wardrobe door making with automatic tool changer, automatic feeding & unloading system? Review the nesting CNC router machine for custom furniture making with functions of cutting, drilling, carving and grooving.

CNC nesting router machine for custom closet door making and personalized wardrobe door making is equipped with automatic feeding & unloading system that could put lumber & composites on table piece by piece automatically, the CNC wood nesting machine will push finished wood sheets in the front of table after cutting, which could save much labor. The automatic tool changer system can drive the CNC router machine to change router bits automatically instead of traditional manual operation, which is fast and safe.

Compared with ordinary CNC router machine, CNC nesting machine has many outstanding advantages and features for custom closet door making and personalized wardrobe door making.

1. Intelligent cross-border protection.

The nesting CNC machine has an intelligent processing cross-border protection function, which can prevent the occurrence of mechanical collision problems. The humanized design makes the processing operation safer

2. Intelligent speed control.

The CNC nesting machine has an intelligent processing speed control function, which can automatically control the processing speed, which can really improve work efficiency, improve product qualification rate, and better extend the service life of the machine.

3. Advanced prediction algorithm.

The CNC router machine adopts advanced three-digit curve prediction algorithm, the curve is stable, and the speed and accuracy of the operation are guaranteed.

4. Simple micro macro control.

The CNC nesting router adopts micro-macro control, which is simple and easy to learn and easy to operate, which is convenient for users to quickly grasp the use of the equipment.

5. Unique pressing device.

The nesting CNC machine adopts a unique pneumatic pressing device, controlled by solenoid valve, and high-speed and high-efficiency feeding.

6. Advanced file processing.

The machine adopts advanced file preprocessing function, intelligently corrects errors in processing files, and can be compatible with processing codes of a variety of software.

7. Advanced control system.

The machine adopts embedded numerical control system, wireless upgrade control function, and anti-interference design to ensure the reliable operation of the system.

8. Good mechanical structure.

The machine adopts seamless welding of steel structure, which has good performance and is not easy to deform.

9. Intelligent continuous engraving function.

The machine has the functions of breakpoint and continuous cutting after power failure, and automatically returns to the origin and corrects errors to ensure processing accuracy.

The nine features of the CNC nesting router machine are so superior that it can be widely used in all aspects of the furniture making industry.

How to choose the right CNC nesting router machine for personalized closet door making and custom wardrobe door making?

1. Strength.

The main factor that affects the strength of the machine is the power of the motor. Generally, the power is more than three kilowatts, and there is also the configuration of the CNC machine parts.

2. Speed.

That is to pay attention to machining efficiency. On the premise that the strength can be achieved, it can be as fast as possible, taking into account the service life of the machine.

3. Function.

Vacuum adsorption: The traditional CNC router machine must use a pressing plate to fix the plate, which inevitably causes the plate to be not fully utilized, or it is troublesome to use. The CNC nesting router machine uses vacuum suction to fix the plate on the carving table. It is divided into six zones and can process plates of different sizes.

Vacuuming: Taking into account the impact of dust on the environment when the machine is cutting the wood, a vacuuming device is added to solve this problem.

Energy saving: The biggest loss of energy comes from the spindle motor. The traditional CNC router machine needs to manually control the spindle cutting motor. It is inevitable that you forget to turn off the spindle after cutting, which will cause energy waste and safety hazards. The spindle of CNC nesting router machine stops automatically after the machine stops working.

Offline: Considering the surrounding environment and convenience of the CNC nesting machine, a new control system is adopted. The computer can be connected to the machine without a data cable, and the operation is simple and the compatibility is strong.

4. Precision.

The machine has to achieve a good working position for a long time regardless of cutting, and the cut is smooth and straight.

This is the most authoritative and professional video for 3D CNC router making wood stairs, review the working video, buy the best 3D CNC woodworking machine.

5 axis CNC bridge saw is a stone cutting machine for marble & granite cutting, edging, grooving, kitchen countertop making, and special-shaped stone cut.

This is an affordable CNC solution for CNC router kits with tool changer, which is equipped with linear automatic tool storage under the gantry.