Everything as expected. Arrived from China in 30 days. Assembly is pretty straightforward. Learning to use the CNC foam router has a short learning curve with the instructions came with it.

4 Axis EPS CNC Router for Foam, Wood, Aluminium Mold Making

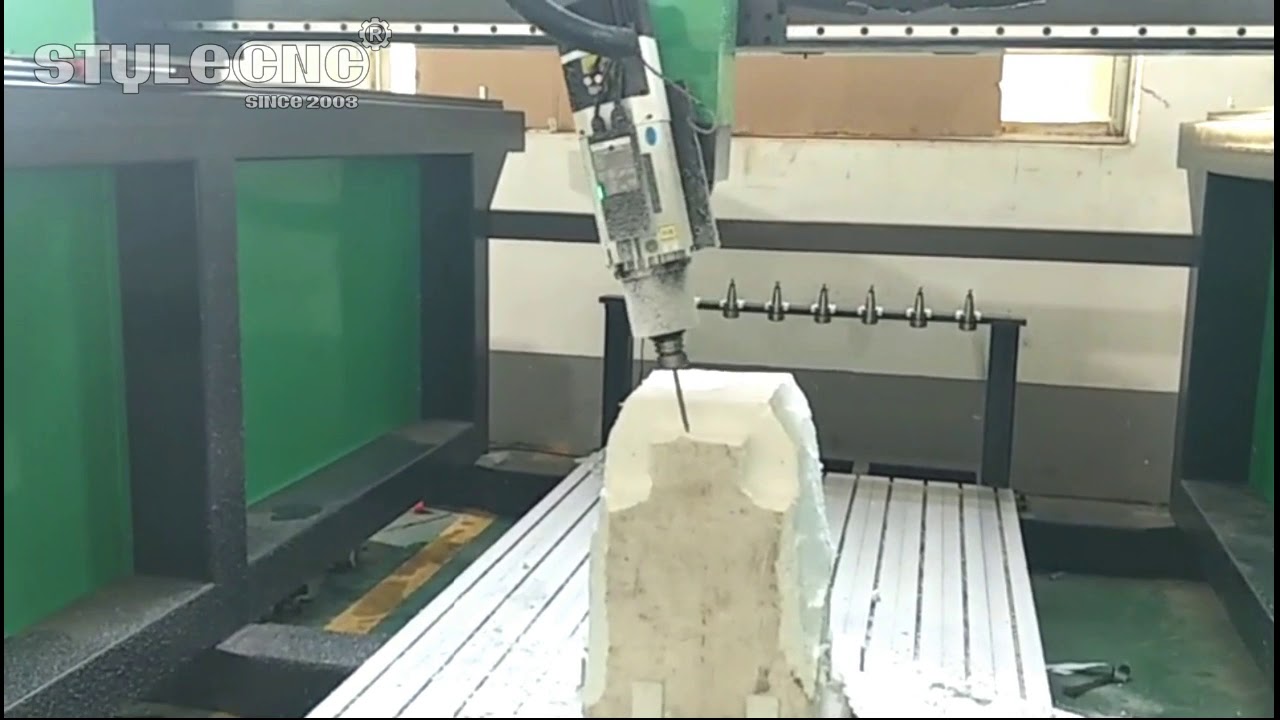

4 axis EPS CNC router machine is used for EPS molding, aluminium mold, wood mold, automotive foam mold, aviation mold, trains mold, 3D musical instruments, bumper, bonnet interior trim mold.

- Brand - STYLECNC

- Model - STM1325-4A

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 4' x 8' (48" x 96", 1300mm x 2500mm)

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

4 Axis EPS CNC Router Machine Configurations

1. Full size working area: 1300mm × 2500mm × 600mm.

2. Italy HSD Spindle 9.0kw air-cooling spindle.

3. Taiwan Syntec controlling system.

4. Japan Yaskawa servo motor and drivers.

5. Delta inverter from Taiwan.

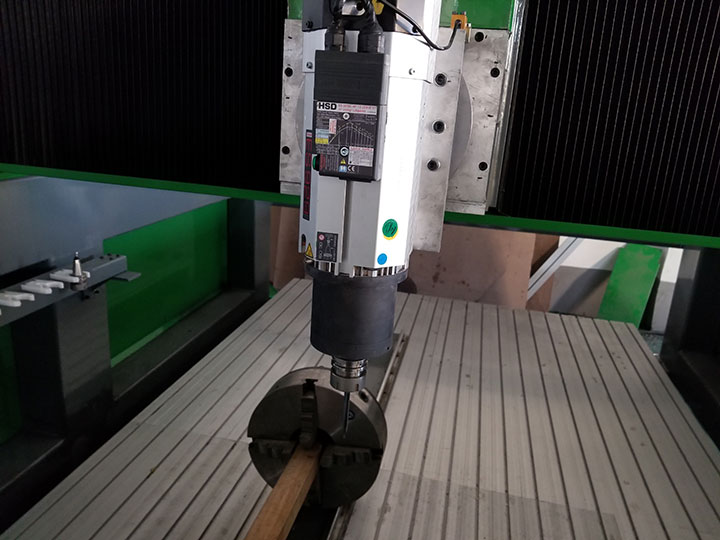

6. Taiwan HIWIN square rails.

7. Japan Omron limited switch.

8. Divided structure bed structure, fixing with screws.

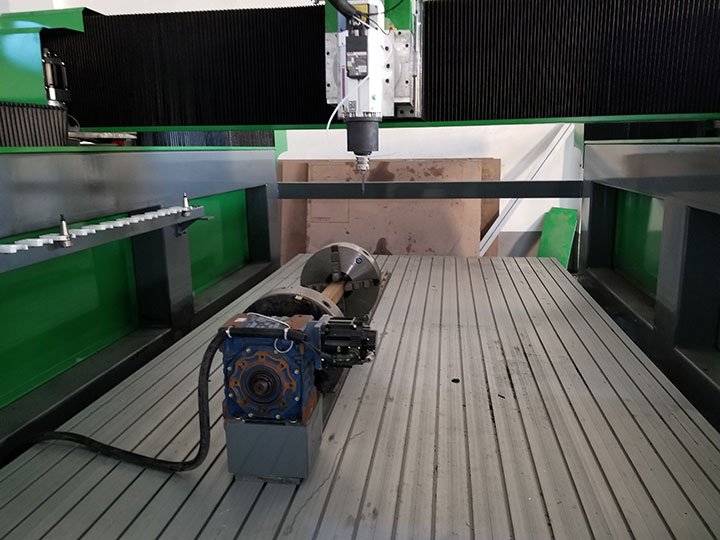

9. Working table: T-slot working table.

10. Japan Shimpo reducer.

Technical Parameters of 4 Axis EPS CNC Router Machine

| Model | STM1325-4A |

| Table Size | 4' x 8' |

| X/Y-Axis Working Area | 1300mm × 2500mm |

| Z-Axis Working Area | 600mm |

| Resolution | 0.5mm |

| Repositioning Accuracy | 0.5mm |

| Lathe Structure | Seamless welded steel structure, better than cast iron one |

| X/Y-Axis Structure | Rack and pinion transmission, Hiwin square guide rail |

| Z-Axis Structure | Germany-made rolling ball screw, Hiwin square guide rail |

| Max. Idling Speed | 30m/min |

| Spindle | 9KW HSD spindle |

| Spindle Rotate Speed | 0-24000r/min, variable speed |

| Working Voltage | AC380V/50Hz |

| Working Mode | YASKAWA Servo motor and diver |

| Command | G-code (HPGL, U00, mmg, plt) |

| CNC Controller | Syntec |

| Tool Diameter | φ3.175 - φ12.7mm |

| Cooling Mode | Air-cooling |

| Work-Holding | By clamp |

| Net Weight | 3000KG |

| Software | Type3, ArtCAM, Ucancam |

4 Axis EPS CNC Router Machine Advantages

1. The whole workbench is made of resin sand casting. Annealing and other heat treatment processes ensure that the overall structure withstands the test of the limit and is solid and reliable.

2. The original Italian HSD high-speed spindle, with a maximum speed of up to 18000rpm, ensures the highest processing efficiency and capacity.

3. The use of high-quality ball bearings, widened linear guides and self-lubricating sliders ensures uniform force in all directions during milling, ensuring accuracy and strength.

4. Taiwan's Syntec controller, efficient reading, and online simulation and monitoring functions to ensure processing efficiency and safety.

5. All models can be customized according to customer needs.

4 Axis EPS CNC Router Machine Applications

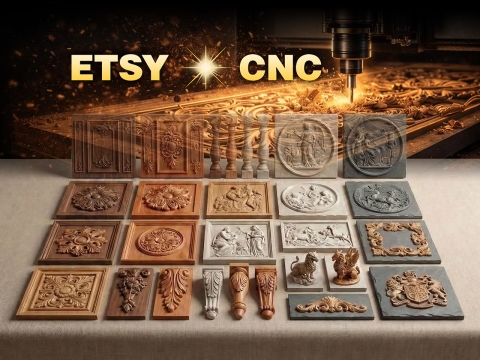

4 axis EPS CNC router machine is ideal for making aluminium mold, wooden mold, EPS and non-metallic carbon materials, automotive foam mold, aviation mold, trains mold, 3D musical instruments, bumper, bonnet interior trim mold.

4 Axis EPS CNC Router Machine Features

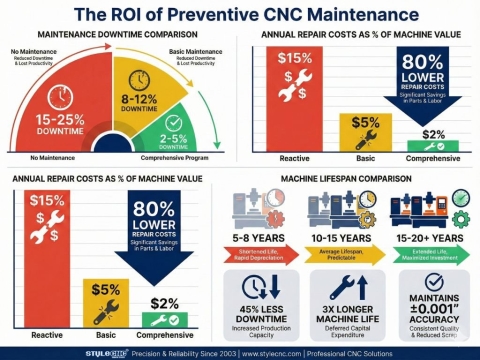

Italy HSD Spindle 9.0kw air cooling spindle:

Taiwan Syntec control system:

Japan YASKAWA servo motor:

Linear ATC tool magazine:

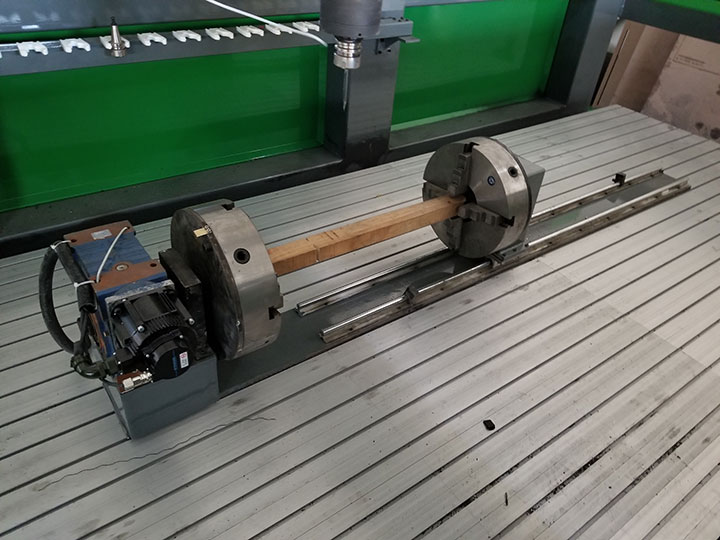

Rotary axis for cylinders:

4 Axis EPS CNC Router Machine Projects