ATC CNC Router with Automatic Tool Changer for Woodworking

This video will show how does an ATC CNC router machine make woodworking projects with automatic tool changer, drill bank and rotary 4th axis.

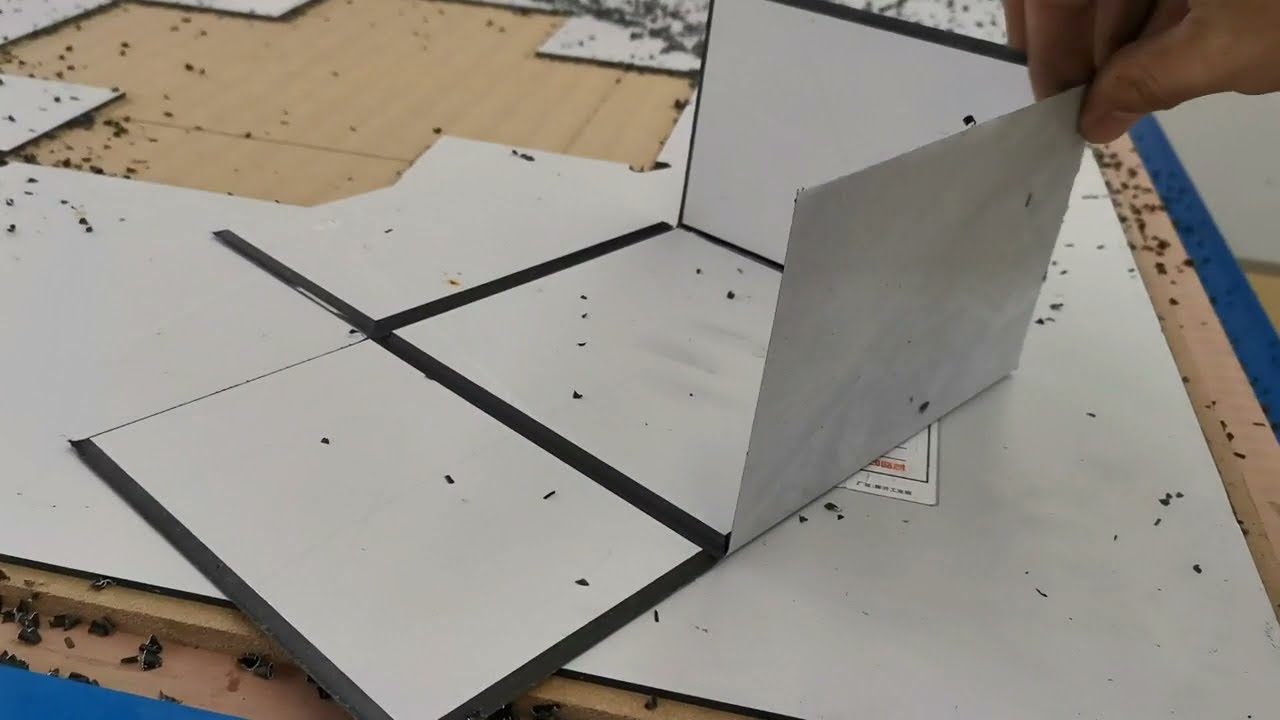

Looking for an ATC CNC router machine with automatic tool changer to cut aluminum plastic composite panels? Review this CNC cutting machine with linear tool changer to start your business.

The CNC router machine is equipped with linear automatic tool changer for cutting aluminum plastic composite panels, which can complete routing, carving, cutting, milling, grooving, and drilling in one step.

The linear ATC CNC router machine has an independent tool magazine, which can automatically replace the required tools during cutting without stopping work. In addition, it can also choose different tools when carving complex patterns.

Why choose a CNC router with automaitc tool changer spindle to cut aluminum plastic composite panels?

First, high accuracy.

This kind of high-quality automatic tool changer spindle has extremely high cutting precision, and its core component is imported bearings, which enables the automatic tool-changing spindle to run at high speed while ensuring accuracy, greatly improving the working stability of the engraving machine, and ensuring the engraving The work goes on smoothly.

Second, strong dust resistance (double-layer closed structure).

The most important factor that affects the life of the automatic tool change spindle is dust pollution. The dust deposits will corrode the core components of the spindle, causing corrosion or damage. The intelligent automatic tool change spindle adopts a double-layer closed structure, which is second to none, which effectively extends the service life of the spindle.

Third, the fuselage is corrosion-resistant (it can keep the fuselage smooth and clean for a long time).

In the design of the intelligent automatic tool change spindle, the practical applicability is fully considered. In order to avoid corrosion and ensure the long-term smoothness of the spindle, the intelligent automatic tool change spindle connects the shaft end to the tool holder to ensure the long-term brightness of the machine body and is not easy to rust.

Fourth, high strength and rigidity.

As the most professional and stable automatic tool change spindle, it adopts high-grade p4 centripetal thrust rolling bearings, which guarantees the stability of the spindle performance and greatly enhances the strength and rigidity of the electric spindle; the spindle speed is larger, It can make the work adaptability of the engraving machine stronger, and can be used for woodworking engraving machines and other processing center machinery.

The above are the advantages of the intelligent automatic tool changer spindle of the CNC router machine. The internal and external components of the automatic spindle have high grade specifications, and have undergone strict precision testing and dynamic balance testing, with extremely low residual values; and its high level of protection and closed structure make the service life of this type of equipment twice as long as that of similar equipment Above, so it is more cost-effective.

This video will show how does an ATC CNC router machine make woodworking projects with automatic tool changer, drill bank and rotary 4th axis.

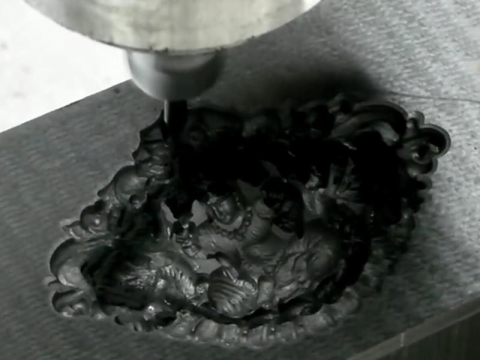

This is a video of CNC metal engraving machine for crafts and mold making, the CNC metal engraver is suitable for engraving, milling, and drilling all metals.

Affordable ATC woodworking CNC router with pneumatic tool changer is an economical CNC machine with 2-4 types of bits, no need to change tools when working.