STM1530C ATC CNC Router Cutting Aluminum with Tool Changer

This video shows how STYLECNC's ATC CNC router with automatic tool changer spindle kit cuts aluminum letters (up to 15mm) at high speed with high precision.

CNC (Computer Numerical Control) routers are versatile machines used for cutting, curving, engraving, and shaping different types of materials. CNC machines are run and controlled by a fully computerized software system. They follow CAD/CAM software commands to maintain precise and repeatable production.

You may wonder what projects you can do with a CNC router. CNC routers have become vital tools in woodworking, fabrication, and workshops. They can perform high-precision and high-efficiency work such as cutting, carving, hollowing, slotting, chamfering, grooving, forming, and milling. It is used for cork, hardwood, mahogany, MDF, solid wood board, synthetic board, multi-layer board, planed board, cork, native wood, PVC, gypsum, aluminum-plastic board, hibiscus board, plexiglass, acrylic, ABS board, foam, plastic, marble, granite, stone, and soft metals for relief carving, cutting, and hollowing.

You'll find the most popular projects made with creative ideas, free and profitable files, and easy-to-follow plans.

Finding free and fun projects for CNC router enthusiasts is more like an opportunity to hone their skills. It is a source of creative inspiration.

Free Projects allow the users to engage in projects that are both enjoyable and accessible. They also offer an economical way for enthusiasts to build their expertise without the constraints of expensive software and plans. Since the machines are fully computerized, knowledge and a free project can make it fun to accomplish your goal.

Hobby CNC kits can make signs, logos, letters, molds, crafts, arts, PCBs, and decorations. Industrial CNC kits can make cabinets, home doors, furniture, kitchenware, musical instruments, tombstones, and art murals. Free and fun projects like these can be a good choice over economic growth alongside increasing experience and expertise.

CNC router technology transforms raw materials into precision-crafted products across countless industries and applications. From intricate wood carvings to industrial prototypes, these computer-controlled machines execute complex designs with repeatable accuracy that manual methods simply cannot match.

This project gallery showcases real work created by STYLECNC customers and demonstrates the diverse capabilities of modern CNC router machines. Whether you operate a small workshop or manage large-scale production, these examples provide practical inspiration for expanding your machining capabilities.

Browse free downloadable files, explore profitable project ideas, and discover which machine configurations deliver optimal results for specific applications. Each project includes material specifications, tooling recommendations, and links to compatible equipment. ...Read More

CNC routers handle an extraordinary range of projects spanning decorative arts through industrial manufacturing. Success depends on matching project requirements with appropriate machine capabilities, tooling selections, and material choices.

Wood remains the most popular CNC router material due to its workability, aesthetic appeal, and broad commercial demand. CNC wood routers process everything from delicate inlays to structural furniture components with consistent precision.

Common woodworking applications include custom cabinetry, decorative mouldings, sign making, musical instruments, and architectural millwork. Softwoods like pine and cedar suit beginner projects and high-volume production where material costs matter. Hardwoods, including oak, walnut, and maple, command premium prices for furniture and decorative pieces requiring durability and visual impact.

Sheet goods expand project possibilities significantly. MDF provides uniform density ideal for painted finishes and intricate relief carvings. Plywood offers structural strength for furniture components and packaging applications. Particle board and melamine serve cabinet manufacturing, where edge banding conceals exposed cores.

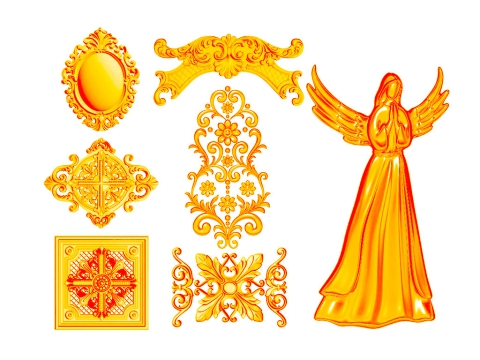

Three-dimensional carving represents CNC routing at its most impressive. 3D CNC router machines interpret STL files to create sculptural elements ranging from decorative rosettes to full figure statuary.

Relief carving depth determines visual impact and machine requirements. Shallow reliefs between 3mm and 10mm work effectively on standard 3-axis machines. Deep relief carvings exceeding 25mm benefit from enhanced Z-axis travel and rigid machine construction. Ball nose end mills in graduated sizes create smooth transitions between carved surfaces during roughing and finishing passes.

Popular 3D projects include religious iconography, portrait plaques, architectural ornaments, custom mouldings, and decorative furniture appliqués. These high-value items command premium pricing that justifies longer machining times and specialized tooling investments.

Commercial signage represents one of the most accessible CNC router markets for new operators. Dimensional letters, routed backgrounds, and carved graphics serve businesses, municipalities, and residential customers seeking professional identification solutions.

Hobby CNC routers handle small-format signs cost-effectively for startup operations. Address plaques, desk nameplates, and directional markers fit compact working envelopes while generating a steady income. Larger format machines accommodate commercial storefront signage, monument signs, and architectural wayfinding systems.

Material diversity distinguishes successful sign shops. HDU foam carves quickly for painted dimensional letters. Acrylic provides illumination options for backlit applications. Aluminum composite panels suit outdoor installations requiring weather resistance. Wood delivers traditional aesthetics for rustic and heritage-themed environments.

Production furniture manufacturing demands machines optimized for sheet processing efficiency. Cabinet CNC machines with nesting capabilities maximize material yield while minimizing handling between operations.

Nesting software arranges cabinet components across full sheets, reducing waste percentages from typical 30% manual layouts to under 15% optimized arrangements. Automatic tool changers enable single setup processing of dados, rabbets, dowel holes, and edge profiles without operator intervention.

Kitchen cabinets, bathroom vanities, closet systems, and commercial casework share similar manufacturing requirements. Consistent panel processing, accurate joinery, and efficient material utilization determine production profitability. Investing in appropriate ATC CNC routers dramatically increases throughput compared to manual tool change operations.

Natural stone presents unique machining challenges that specialized equipment addresses effectively. Stone CNC machines feature enhanced rigidity, appropriate spindle configurations, and dust management systems suited for granite, marble, and engineered stone processing.

Memorial and monument work represents significant stone CNC applications. Cemetery headstones, memorial plaques, dedication markers, and architectural inscriptions require precision lettering and graphic reproduction. Diamond tooling creates clean cuts in abrasive materials while maintaining dimensional accuracy across production runs.

Countertop fabrication adds another revenue stream for stone-capable shops. Sink cutouts, edge profiles, and surface texturing transform raw slabs into finished installations. Integration with templating systems enables custom kitchen and bathroom projects with minimal rework.

Aluminum, brass, and soft steel expand CNC router applications into light metal fabrication. Metal CNC machines incorporate features addressing chip evacuation, coolant delivery, and enhanced rigidity for successful metal processing.

Typical metal projects include custom enclosures, instrument panels, decorative hardware, prototype components, and architectural metalwork. Aluminum nameplates and identification tags serve industrial labeling requirements. Brass fixtures and decorative elements command premium prices for luxury applications.

Spindle selection significantly impacts metal machining success. Higher horsepower ratings sustain cutting forces in dense materials. Speed control maintains optimal surface footage across varying tool diameters. Proper chip load calculations prevent tool breakage and ensure surface finish quality.

Complex geometry demands additional machine axes beyond standard XYZ configurations. 4 axis CNC routers add rotational capability for cylindrical workpieces, including table legs, columns, balusters, and decorative turnings.

5 axis CNC machines enable simultaneous multi-directional cutting for complex sculptural forms, aerospace components, and architectural elements impossible on simpler configurations. Continuous surface machining eliminates repositioning requirements while maintaining accuracy across compound curves.

Prototype development benefits significantly from multi-axis capabilities. Industrial designers and engineers create functional models verifying form, fit, and function before committing to production tooling. Rapid iteration accelerates product development timelines while reducing prototype costs compared to outsourced manufacturing.

Successful CNC operations align project complexity with machine capabilities. Attempting projects exceeding equipment limitations produces frustration, wasted materials, and potential machine damage.

Evaluate your machine's working envelope, spindle power, axis configuration, and rigidity before committing to specific project types. Review CNC videos demonstrating similar work on comparable equipment. Consult customer reviews describing real-world performance across various applications.

Start with projects well within your machine's capabilities while developing operator skills and process knowledge. Gradually increase complexity as confidence builds. Document successful parameters for repeatable results across production runs.

Proper tooling selection proves equally important as machine capability. Quality CNC router bits and accessories from reputable suppliers outperform bargain alternatives in cut quality, tool life, and consistency. Matching cutter geometry to specific materials and operations optimizes results while protecting equipment investments.

Documenting completed projects creates valuable marketing assets and operational references. Photography showcasing finished work attracts customers seeking similar results. Process documentation enables consistent reproduction when repeat orders arrive.

STYLECNC supports customers throughout their CNC journey with comprehensive technical support, CNC software resources, and ongoing training assistance. Our engineering team helps match equipment configurations to specific project requirements, ensuring successful outcomes from initial investment through production scaling.

A free project can only be fun when you are beautifully done with it. To complete a project in a nice and précised way, one must follow the safety instructions to avoid any type of damage to the machine and product.

These projects are available for beginners, expert, and advanced level. Thus you must consider choosing one of them very accurately. After the project is selected follow the safety measures to make a dream project.

⇲ Make sure the basic materials and tools are taken properly.

⇲ Read the guidelines provided by the manufacturer.

⇲ Wear PPE, safety glasses, and closed-toe shoes.

⇲ Use clamps or fixtures to securely fasten the workpieces to the machine.

⇲ Never leave an operating CNC router machine.

Check the machine for wear, damage, or malfunction on a daily basis.

Need nesting CNC router to make rocking chair with solid wood, MDF, or plywood? Review the rocking chair projects, free download the DWG, CDR, and DXF files.

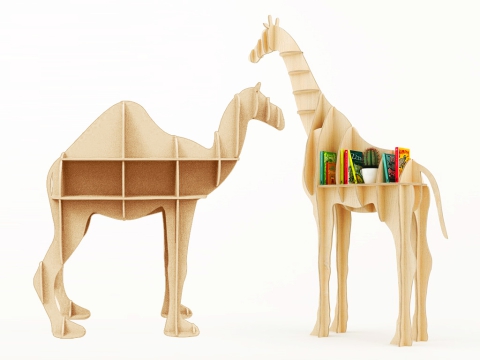

Free download nesting CNC router PLT files for 3D furniture models of animal, including unicorn shelf, giraffe bookcase, and camel display storage.

Looking for 3D CNC router STL files for your woodworking projects? Free download the most popular 3D woodworking files to fit your CNC machining requirements.

Check out the 5 axis CNC machining for 3D EPS solid model of toilet prototype as your reference to buy an affordable 5 axis CNC router machine for 3D modeling.

Looking for 3D DXF files, 3D STL files for CNC routing ideas, review the free 3D CNC router files for beginners with relief carving to fit your CNC projects.

3D Santa Claus carving projects for Christmas by wood CNC router from STYLECNC, which will be a good reference for you to buy a CNC wood router.

Here is the best collection of the most popular wooden sign and plaque carving projects built using STYLECNC's compact and small CNC router machine STG6090.

Stone CNC router is used for relief carving text and graphics on murals, marble, granite, tombstone, milestones, blue stone, sandstone, tile, and more stones.

Lebanon customer uses STM1325 wood CNC router to cut 2D MDF design to make nice table and sofa, and cut wood to make interior decoration.

This video shows how STYLECNC's ATC CNC router with automatic tool changer spindle kit cuts aluminum letters (up to 15mm) at high speed with high precision.

Watch the demo video to see how a nesting CNC router machine make panel furniture with automatic tool changer, self feeder, discharge table with conveyor belt.

You will understand how to setup, install, and use LNC CNC controller for ATC CNC routers with automatic tool changer and CNC machining centers in this video.