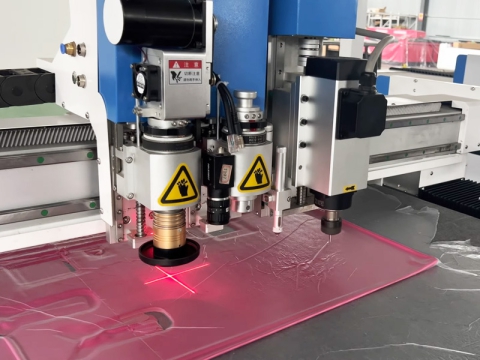

4-Axis CNC Foam Router for Carving 3D Sculptures and Molds

This is a complete guide (user-friendly for beginners and professionals) to carving and cutting exquisite 3D foam sculptures and molds using 4-axis CNC router.

This video will show you the digital cutter tips and tricks for cutting and routing thick foam up to 100mm with the pneumatic oscillating tool (POT). Due to the large clearance height of the foam cutter, foams with a thickness of up to 100mm can be cut.

Except for foam cutting, the digital cutting machine can also be equipped with different tools to cut different materials, including corrugated cardboard, fiberboard, honeycomb board, gasket, and so on.

Features

1. The digital cutter adopts the best multi-axis, multi-channel control system, which has the characteristics of high response, high anti-interference and high stability.

2. The digital cutting machine adopts the design concept of replaceable head, the tool head is not fixed and integrated, and the tool head of different functions can be easily replaced and added according to the actual work needs and the expansion of the business scope;

3. The servo motor drives the screw control mode, and the computer can be preset to store the knife depth and knife pressure according to different needs. Compared with the old-fashioned pneumatic head, it is a goodbye to the history of manual adjustment of knife depth and knife pressure according to experience. It is convenient carry out digital fine-tuning, and completely solve the problem that the pneumatic pressure cannot fluctuate with temperature and time, and cannot be constant;

4. The controller has been upgraded from the era of the computer motherboard card in the past to the era of high-performance integrated circuit controllers. It can be connected to any ordinary computer (including notebooks), and no special high-end computer is needed. If the computer fails, the ordinary can be easily replaced. Use the computer to operate the equipment, completely eliminating the paralysis of the cutting equipment caused by the failure of the computer link;

5. Taking into account the actual environmental factors of the customer, the anti-interference operation screen is specially configured, and it will not be affected by the surrounding electronic environment when working, and will not spend the screen;

6. The data interface is a network interface, which can realize remote upgrade and maintenance, fast transmission speed and long distance, can be simultaneously transmitted with multiple computers, can be remotely controlled and upgraded, etc. Compared with the old serial port, parallel port, PCl interface is more advanced, more convenient;

7. Configure vibrating knife, drag knife, round knife (optional active wheel knife, pneumatic round knife) and other tools and drawing pen tools. Depending on the different needs of different materials, such as writing line drawing, dotted line cutting, Half-cutting, full-cutting and other functions can cut various flexible materials such as sponge compound degree, XPE material, silk base, degree leather, soft glass, silicone, rubber material and so on.

8. It can complete the touch cutting, creasing and forming of flexible materials such as leather stamp paper and plastic without the need of knife die and die cutting machine, which can save a lot of manpower, knife die and die cutting machine cost. Instead of traditional paper manual development design and proofing, shorten the corresponding research and development time; also to create a set of standardized and practical complete solutions to meet customers' production goals of low volume, multiple orders and multiple styles.

9. Rolling table equipment, the platform can be customized in a wide range, the theoretical cutting length is unlimited, suitable for automatic feeding and cutting of coils and plates, saving manual configuration of multi-function cutting tools, convenient for marking of complete sets of materials, easy to find, and convenient for production.

Precautions

1. When moving the worktable of the digital foam cutter, the moving speed should be correctly selected according to the distance from the workpiece to prevent collisions when moving too fast.

2. When programming, the correct processing technology and processing route should be determined according to the actual situation, to prevent the workpiece from being scrapped or cut off in advance due to insufficient processing position or insufficient edge strength.

3. Before thread cutting, you must confirm whether the program and compensation amount are correct.

4. Observe and judge the processing stability of the digital cutter when starting cutting, and adjust it in time when it is found to be bad.

5. During the processing of the digital foam cutter, it is necessary to check and supervise the cutting conditions frequently, and find any problems immediately.

This is a complete guide (user-friendly for beginners and professionals) to carving and cutting exquisite 3D foam sculptures and molds using 4-axis CNC router.

Looking to buy an automatic fabric cutting machine for clothing business? Watching this video of digital cutting multi-layer fabric will give you more options.

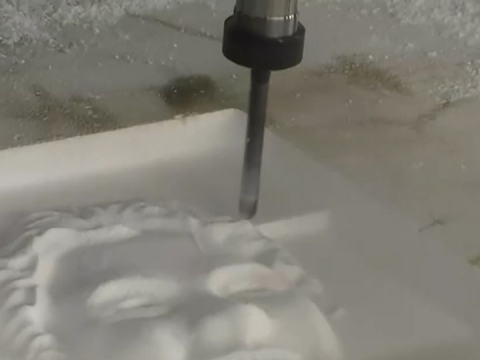

CNC foam router is used for milling and cutting large EPS foam mold, especially for automotive mold, ship mold, aviation and train mold.