Laser is a kind of light that has no direct existence in nature and has characteristics such as good directivity, high brightness, good monochromaticity and good coherence. Although the laser is light, it is obviously different from ordinary light. The laser depends on spontaneous radiation only for a very short period of time. The subsequent process is completely determined by the laser radiation. Therefore, the laser has a very pure color and almost no divergent directivity.

The laser has extremely high luminous intensity, and at the same time has high coherence, high intensity, and high directivity. After the laser is generated by the laser, it is transmitted by the reflector and irradiated by the collection mirror to the processed object, which makes the processed object (surface) powerful The heat energy and the temperature increase sharply, so that the point will quickly melt or vaporize due to high temperature, and cooperate with the running track of the laser head to achieve the purpose of processing.

The speed of the laser head movement is usually expressed in IPS (inches per second). High speed brings high production efficiency. Speed is also used to control the cutting depth. For a specific laser intensity, the slower the speed, the greater the cutting or engraving depth.

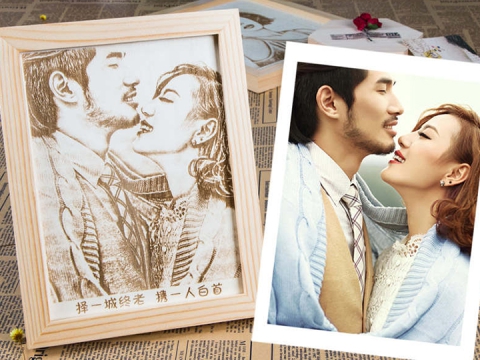

Laser engraver is a kind of mechanical equipment that is currently engaged in processing and manufacturing. It is widely used in products related to people's daily life, such as clothes, shoes, hats, bags, toys, trademarks, crafts and other industries. The function is mainly referred to engraving and cutting.

The working principle of laser engraver refers to dot matrix engraving and vector cutting. Dot matrix engraving resembles high-resolution dot matrix printing. The laser head swings left and right, each time engraving a line composed of a series of points, and then the laser head moves up and down to engrave multiple lines at the same time, and finally constitutes a full-page image or text. Scanned graphics, text and vectorized graphics can use dot matrix engraving. Vector cutting is different from dot matrix engraving. Vector cutting is performed on the outer contour of the text.

We usually use this mode to cut through on wood, acrylic, paper and other materials, and can also perform marking operations on the surface of various materials. The laser engraving speed refers to the speed of the laser head movement, usually IPS ( Inches per second) means that high speed brings high production efficiency. The speed is also used to control the cutting depth. For a specific laser intensity, the slower the speed, the greater the laser cutting or laser engraving depth. You can use the engraving machine panel to adjust the speed, or use the computer's print driver to adjust. In the range of 1% to 100%, the adjustment range is 1%.

The advanced motion control system of the laser engraving machine can enable you to obtain ultra-fine engraving intensity when engraving at high speed. For a specific engraving speed, the greater the intensity, the greater the depth of cutting or engraving. You can use the engraving machine panel to adjust the intensity, or you can use the computer's driver to adjust. In the range of 1% to 100%, the adjustment range is 1%. The greater the intensity, the greater the equivalent speed.

The size of the laser beam spot can be adjusted with lenses of different focal lengths. The small spot lens is used for high-resolution engraving. The large spot lens is used for lower resolution engraving, but it is the best choice for vector cutting. The standard configuration of the new equipment is a 2.0-inch lens. The spot size is in the middle, suitable for various occasions. The engravable materials include: wood products, organic glass, metal plates, glass, stone, crystal, Corian, paper, two-color plates, aluminum oxide, leather, resin, plastic sprayed metal.