Foamed plastic is a type of polymer material formed by a lot of gas micropores dispersed in solid plastics. It has the advantages of heat insulation, light weight, shock resistance, sound absorption, corrosion resistanceand moisture resistance. The most common traditional foamed plastics are refer to polystyrene (PS), polyurethane (PUR), phenolic resin (PF), polyethylene (PE) and polyvinyl chloride (PVC).

Foamed plastics are classified into soft, semi-rigid and rigid foams based on their flexibility. Rigid foam plastics are used as sound insulation materials and thermal insulation materials for pipes and containers, shock-absorbing packaging materials and floating materials. Soft foam plastics are used as foam artificial leathers and cushion materials.

What is Insulation Foam?

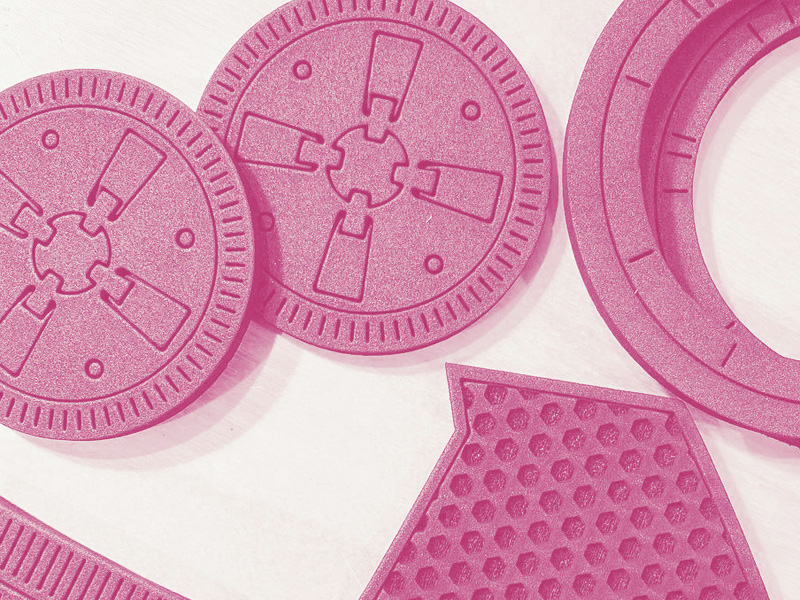

Insulation foam is a type of rigid foam plastic. The polymer that constitutes the insulating foam is in a crystalline or amorphous state, and its glass transition temperature is higher than normal temperature. Therefore, the insulation foam has a harder texture at normal temperature. So, how to cut it into different shapes with a laser machine, and how to engrave different patterns on its surface.

First of all, we need to understand what is a laser foam engraving and cutting machine and how does it work?

What is Laser Foam Engraver Cutting Machine?

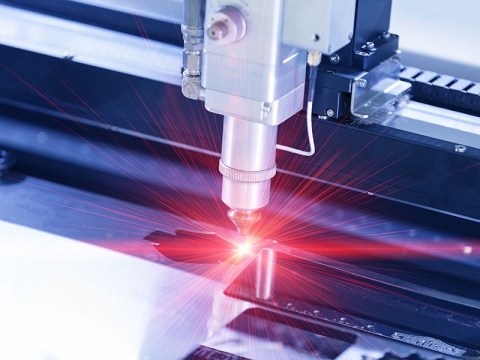

The laser foam engraving and cutting machine is an automatic device that uses the high heat of the laser beam emitted from the laser tube to transfer to the surface of the foam. It has accurate cutting, fast speed, simple operation, personalized processing and precision, laser head running trajectory simulation display, multiple path optimization functions, and automatic typesetting system to ensure maximum material saving and cost saving, especially suitable for insulation foam engraving and cutting.

How Does Laser Foam Cutter Engraving Machine Work?

With the movement of the relative position of the laser beam and the foam, the foam is finally engraved with a pattern or a slit is formed, so as to achieve the purpose of carving and cutting foam.

It is mainly used to cut various polymer materials such as engineering plastics, foam plastics, general plastics. The power of this type of machine is generally not too high, and the calorific value is not high, so the cutting width is not very large.

How a Laser Machine Cuts and Engraves Pink Insulation Foam?

The laser machine is a highly flexible tool that enables everything from prototyping construction to mass production. You can start right from the design program, which is especially critical for rapid prototyping. Compared to complex water jet cutting processes, laser equipment is significantly faster, more flexible and more efficient. Insulation foam cutting with a laser creates clean fused, sealed edges.

To leave a notch on the insulation foam, a 60W laser generator is more than enough. Generally speaking, a laser generator of more than 80W is required to cut the insulation foam. The specific wattage depends on the thickness of the insulation foam and your requirements. cutting efficiency. Generally speaking, the higher the power, the thicker the foam can be cut, and the faster the cutting speed.

Before starting the laser engraving machine, you should check whether the power supply is normal, whether the cooling water tank is full of deionized water, and whether the circulating water pump and the inlet and outlet pipes are normal. Check that the emergency stop button of the laser is not pressed, and there are no debris on the upper and inside of the machine. Check that the lenses are clean. If there is dirt, it must be cleaned before use. Check the mechanical part to confirm that there is no debris on the processing table. Check whether the electromagnetic air pump works normally.

If all is well, let's start engraving and cutting pink insulation foam with a laser machine.

Step 1. Turn on the main power switch, and turn on the machine control power switch. After the system self-check is completed, each axis of the machine returns to the reference point.

Step 2. Turn on the power of the control cabinet, turn on the circulating water pump, and confirm that there is water flowing out of the water outlet.

Start the chiller and check the water temperature and pressure (normal water pressure is 5bar). Three minutes after the chiller is powered on, the compressor starts, the fan rotates, and cooling begins.

Step 3. Start the air compressor and air dryer. After the chiller drops to the set temperature (set to 21 degrees), turn on the main power of the laser generator.

Step 4. Insert the laser power key into the key hole of the switch, turn the key clockwise to turn on the laser power, and wait for the system to be normal (about 30 seconds).

Step 5. Export directly from the computer to the laser software through the data cable, or you can choose to export to a USB flash memory, and then download to the laser machine.

Step 6. When the word "READY" appears on the laser panel, apply high voltage.

Step 7. Confirm the material type, material thickness and material size before cutting. Lay out the insulation foam to be engraved and cut on a work surface.

Step 8. Use a standard ruler to adjust the height of the laser head, and adjust the plate so that the edge is parallel to the X-axis and Y-axis of the machine tool to prevent the laser head from working outside the range of the plate.

Step 9. Move the Z-axis to the starting point of the work, simulate the program to be executed, ensure that there is no soft limit alarm, enter the editing mode, and adjust the power, speed, punching time type and thickness according to the material.

Step 10. After the above items are normal, you can switch to the execution state, and you can start to engrave and cut insulation foam.

When the work is done, shut down in the following order:

1. After the processing is completed, the prompt bell rings, open the cabin cover, and take out the processed items.

2. Turn the key counterclockwise to turn off the laser, and turn off the circulating water pump after 1 minute.

3. Clean up processing residues in the machine.

4. Power off the control cabinet.

5. Turn off the air dryer and air compressor.

Things To Consider

1. Strictly follow the operation sequence to open and close.

2. Unqualified personnel are prohibited from operating and repairing the machine.

3. During the working process, it is strictly forbidden to enter the workbench to ensure the safety of human and machine. When the operator encounters a dangerous situation, the operator must concentrate and press the "emergency stop" button as soon as possible.

4. The adjustment of the optical path and the laser head in the follow-up mode must be carried out in the correct operation sequence to ensure the safety of the human and machine.

6. Every time you start the machine, you must return to the reference point, check and clean the focusing mirror, calibrate the coaxiality of the beam nozzle, turn on the auxiliary gas for cutting, and the pressure in the bottle should not be too large (Less than 1Mpa).

In a word, compared with traditional engraving and cutting methods, laser engraving and cutting pink insulation foam is fast, efficient, high precision, and the surface will not be deformed. Whether it is a hobbyist or an industrial mass production, this is a good choice.