CNC machine maintenance is the systematic process of inspecting, cleaning, lubricating, and servicing computer numerical control equipment to ensure optimal performance, prevent breakdowns, and extend machine lifespan. A well-executed maintenance program can reduce unplanned downtime by up to 45% and increase machine accuracy by maintaining tight tolerances.

Whether you operate a CNC router for woodworking, a fiber laser cutting machine for metal fabrication, or any other CNC equipment, proper maintenance protects your investment and maintains production quality.

Quick Reference: Maintenance Frequency at a Glance

| Frequency | Key Tasks |

|---|---|

| Daily | Clean chips, check fluids, inspect guards, test E-stops |

| Weekly | Lubrication check, coolant test, filter inspection |

| Monthly | Spindle runout, backlash check, electrical connections |

| Annual | Full calibration, wear part replacement, spindle service |

Why CNC Machine Maintenance Matters?

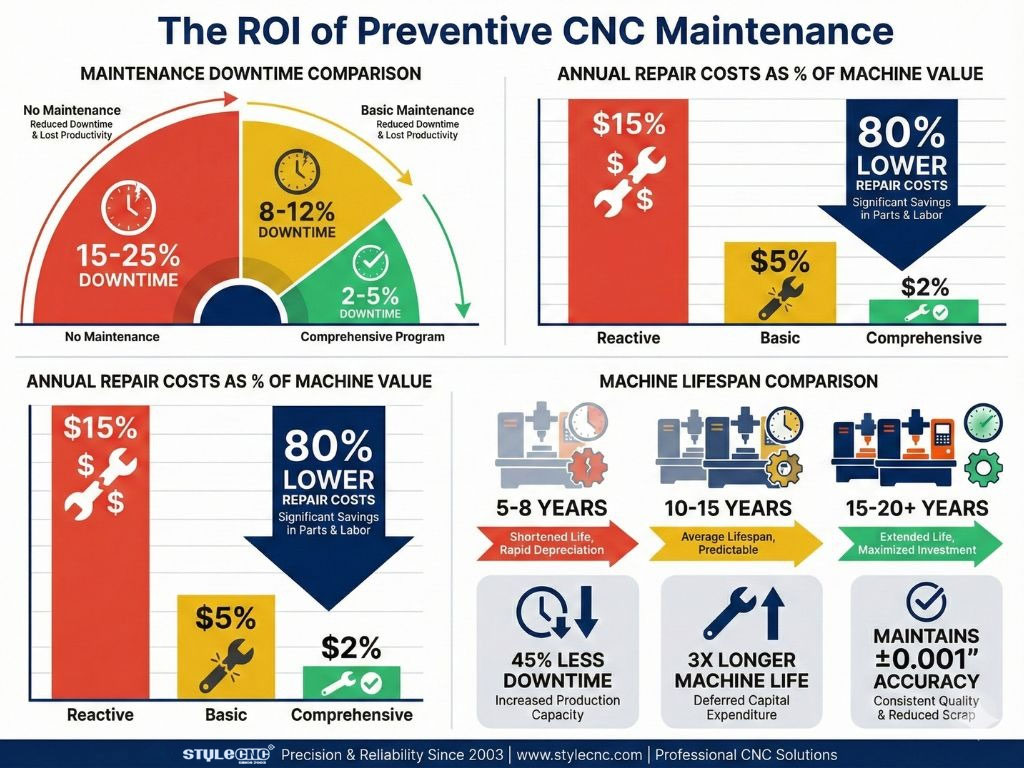

CNC machines represent significant capital investments ranging from $15,000 to over $500,000. Industry research shows reactive maintenance (fixing problems after they occur) costs three to ten times more than preventive programs.

Benefits of proper maintenance include:

• Machine accuracy stays consistent when components receive regular attention.

• Production quality improves with parts manufactured within tighter tolerances.

• Operating costs decrease through reduced energy consumption.

• Emergency repairs become rare rather than routine.

• Component lifespan extends significantly, protecting your investment.

Impact of Maintenance on CNC Operations

| Factor | No Maintenance | Basic | Comprehensive |

|---|---|---|---|

| Downtime | 15-25% | 8-12% | 2-5% |

| Machine Life | 5-8 years | 10-15 years | 15-20+ years |

| Repair Costs | 8-15%/year | 3-6%/year | 1-3%/year |

Daily CNC Machine Maintenance Checklist

• Time required: 15-30 minutes per shift.

• Daily tasks form the foundation of effective CNC maintenance. These quick inspections prevent minor issues from becoming costly failures.

Pre-Operation Checklist

• Check coolant level in reservoir and top off if needed.

• Verify lubricant levels in all lubrication systems.

• Confirm air pressure reads 80-100 PSI on pneumatic gauges.

• Inspect way covers and bellows for damage or debris.

• Test all emergency stop buttons for proper function.

• Listen for unusual sounds during warm-up cycle.

• Verify all safety interlocks engage correctly.

End-of-Day Checklist

• Remove all chips and swarf from work envelope.

• Vacuum fine particles from machine surfaces.

• Wipe down exposed slideways with clean lint-free cloth.

• Clean spindle nose area and tool holder taper.

• Empty chip trays and clean chip conveyor.

• Return all axes to home position.

• Power down according to manufacturer procedure.

Weekly CNC Maintenance Tasks

Time required: 1-2 hours.

Lubrication System Checklist

• Observe auto-lube pump cycles during operation.

• Verify lubricant reaches all distribution points.

• Manually grease fittings not on auto-lube system.

• Check way oil reservoir level.

• Inspect for proper oil film on all slideways.

• Look for signs of over-lubrication or leaks.

If you notice axis sticking or inconsistent movement, inadequate lubrication is often the root cause. Review our guide on common CNC problems and solutions for troubleshooting help.

Coolant System Checklist

• Test coolant concentration with refractometer (target: 5-10%).

• Measure coolant pH level (target: 8.5-9.5).

• Skim tramp oil from coolant surface.

• Check coolant pump operation and flow rate.

• Inspect coolant lines for leaks or blockages.

• Clean coolant nozzles if flow appears restricted.

Monthly Maintenance Procedures

Time required: 4-8 hours (may require technical support)

| Component | What to Check | Action Required |

|---|---|---|

| Spindle | Runout with dial indicator | Service if >0.0002" |

| Ball Screws | Backlash on each axis | Adjust preload or replace |

| Linear Guides | Play or rough motion | Clean and re-lubricate |

| Electrical | Cables and terminals | Tighten loose connections |

| Filters | Air, oil, and coolant filters | Clean or replace |

| Belts | Tension and wear condition | Adjust tension or replace |

Quarterly and Annual Maintenance

Quarterly Tasks (Every 3 Months)

• Perform geometric accuracy checks with precision instruments.

• Verify axis squareness and parallelism.

• Test positioning accuracy against specifications.

• Document all measurements for trend tracking.

• Flush and replace coolant if contaminated.

• Test all safety devices and interlocks.

• Inspect and clean the electrical cabinet interior.

Annual Overhaul Tasks

• Replace all seals, wipers, and filters.

• Service spindle (every 8,000-12,000 hours).

• Replace worn belts and drive components.

• Recalibrate tool measurement systems.

• Update controller software and firmware.

• Perform full machine geometry calibration.

• Replace ball screw nuts if backlash exceeds limits.

• Keep genuine spare parts on hand for common wear items to minimize downtime during scheduled service.

Industry-Specific Maintenance Tips

Wood CNC Router Maintenance

Woodworking creates unique challenges due to fine dust infiltration:

• Install and maintain effective dust collection systems.

• Check dust collector filters weekly.

• Inspect spindle cooling passages for sawdust buildup.

• Clean electrical cabinets monthly to prevent dust accumulation.

• Apply corrosion protection in humid environments.

• Quality CNC router parts designed for dust-prone environments include enhanced sealing features.

Metal CNC Machine Maintenance

Metal machining requires extra attention to chip management and coolant care:

• Evacuate chip trays and conveyors frequently.

• Maintain higher coolant concentrations for heat management.

• Monitor for metal fines accumulating in coolant.

• Change filters more frequently based on material removal rates.

• Inspect way covers for chip damage regularly.

CNC Maintenance Costs and Budgeting

Annual maintenance costs for properly maintained CNC equipment typically range from 1% to 5% of the original purchase price. Here's what to expect:

Service Contract Options:

• Basic agreements (scheduled maintenance + phone support): $2,000-$8,000/year.

• Comprehensive agreements (emergency service + parts): $8,000-$25,000/year.

• Premium coverage (all-inclusive + priority response): $15,000-$40,000/year.

In-House Maintenance Budget Items:

• Lubricants and coolants: $500-$2,000/year.

• Filters and consumables: $300-$1,500/year.

• Common replacement parts: $1,000-$5,000/year.

• Calibration tools and equipment: $500-$3,000 (one-time).

Frequently Asked Questions

How often should I lubricate my CNC machine?

Machines with automatic lubrication systems typically cycle every 15-60 minutes during operation. For manual lubrication points, follow the manufacturer's chart, which usually specifies daily, weekly, or monthly intervals for different components. High-usage machines may require more frequent lubrication.

What causes most CNC machine breakdowns?

The majority of CNC failures stem from preventable causes:

• Inadequate lubrication: 40% of mechanical failures.

• Contamination from chips and coolant: 25%.

• Electrical issues from loose connections: 20%.

• General wear from deferred maintenance: 15%.

Can I perform CNC maintenance myself?

Daily and weekly tasks are designed for operator-level performance. Monthly inspections require more technical knowledge but remain manageable with proper documentation. Quarterly calibrations and annual overhauls typically benefit from professional service, especially for precision calibration work.

How do I know when spindle bearings need replacement?

Watch for these warning signs:

• Increasing spindle noise (whining or grinding sounds).

• Elevated operating temperature.

• Visible runout at the tool interface.

• Degraded surface finish on machined parts.

• Bearings typically last 15,000-25,000 operating hours.

What records should I keep for CNC maintenance?

Maintain detailed logs including:

• All service activities with dates and technician names.

• Parts replaced with part numbers and sources.

• Calibration measurements and trends.

• Operating hour readings at each service interval.

• Problems encountered and corrective actions taken.

What temperature should my CNC machine operate at?

Most CNC machines perform best in environments maintained between 59°F-77°F (15°C-25°C) with relative humidity between 40-60%. Spindle operating temperatures vary by design but typically run 20-40°F above ambient. A sudden temperature increase of more than 15°F from normal operating temperature indicates potential bearing or lubrication problems requiring immediate attention.

How do I prevent rust on my CNC machine?

Rust prevention requires consistent attention:

• Wipe exposed metal surfaces with way oil or rust preventive daily.

• Control shop humidity below 60% when possible.

• Never leave water-based coolant sitting on surfaces overnight.

• Apply rust inhibitor spray before extended shutdowns.

• Keep way covers and bellows in good condition to protect precision surfaces.

Building Your CNC Maintenance Program

Start with the basics: daily cleaning, weekly lubrication checks, and prompt attention to any unusual machine behavior. Build from there by implementing monthly inspections and establishing relationships with qualified service providers for specialized procedures.

Key takeaways for CNC maintenance success:

• Consistency matters more than perfection.

• Document everything for trend analysis.

• Address small issues before they become big problems.

• Invest in proper training for maintenance personnel.

• Keep critical spare parts in stock.

• Build relationships with qualified service providers.

The investment in preventive maintenance pays dividends through increased machine availability, improved part quality, and extended equipment lifespan. Proper maintenance protects your investment and ensures your equipment continues delivering the precision and reliability that modern manufacturing demands.

STYLECNC Machine Maintenance and Support Services

Since 2003, STYLECNC has supported customers across 180+ countries with comprehensive CNC service solutions. Our commitment extends far beyond delivering quality machines. We provide ongoing STYLECNC machine support through every stage of your equipment's lifecycle, from installation and training to routine maintenance and emergency repairs.

STYLECNC CNC service includes dedicated technical teams available via phone, email, WhatsApp, and video call to troubleshoot issues in real time. Our engineers can remotely diagnose problems, guide you through repairs, and recommend preventive measures tailored to your specific application. For complex issues requiring hands-on attention, STYLECNC repair service connects you with authorized technicians and service partners worldwide who understand our machines inside and out.

Every STYLECNC machine comes with detailed maintenance documentation, training videos, and access to our online support portal. We stock genuine replacement parts and ship globally to minimize your downtime. Our STYLECNC service center team assists with annual maintenance planning, calibration scheduling, and software updates to keep your equipment running at peak performance.

Whether you need routine STYLECNC machine maintenance guidance or urgent technical assistance, our customer service team responds quickly because we understand that every hour of downtime impacts your production and profitability. Partner with STYLECNC for machines backed by service you can count on.

Final Words

Your CNC machine is more than just equipment. It represents your capability to deliver precision, meet deadlines, and grow your business. Every minute of unplanned downtime costs money and damages customer relationships. The maintenance practices outlined in this guide are not suggestions. They are proven strategies used by successful manufacturers worldwide.

Start today. Print the daily checklist and post it near your machine. Commit to just 15 minutes of maintenance each day. Within weeks, you will notice smoother operation, fewer alarms, and better part quality. Within months, you will wonder how you ever operated without a structured maintenance program. Your machine will thank you with years of reliable service, and your bottom line will reflect the wisdom of preventive care over reactive repairs.