Laser Wood Cutting Machine Applications

Laser wood cutting machine is used for cutting and engraving wood arts, wood crafts, wood gifts, wood boxes, wood signs, wood logos, and wood letters.

2000W fiber laser cutter is an automatic low-power laser metal cutting machine to cut stainless steel, mild steel, aluminum, copper and brass to make custom metal signs, logos, parts, letters, jewelry, 3D models and puzzles.

2000W fiber laser cutting machine is a precision metal cutting machine suitable for metal processing of stainless steel, mild steel, carbon steel, alloy steel, spring steel, copper, aluminum, gold, silver, and titanium.

2000W fiber laser cutting machine is typically used for making metal billboards, advertising characters, sheet metal parts, high and low voltage electrical cabinets, kitchen utensils, glasses frames, jewelry, artworks, crafts, pipes, models and puzzles.

• High laser beam quality - Smaller laser focus point allows for higher cutting accuracy and quality.

• Fast cutting speed - The cutting speed is 2-3 times that of CO2 laser cutters of the same power, making it more efficient.

• Stable operation - The use of the world's top fiber laser generator allows for stable performance, and the service life of core components can reach 100,000 hours.

• Low cost - The photoelectric conversion rate can reach 25% to 30%, 3 times higher than CO2 laser, making it energy-saving and environmentally friendly.

• Low power consumption - Only 20% to 30% of traditional CO2 laser cutting machines.

• Low maintenance cost - No reflectors are required for fiber transmission, saving maintenance costs.

• Easy to use - User-friendly and easy to get started with a short learning curve.

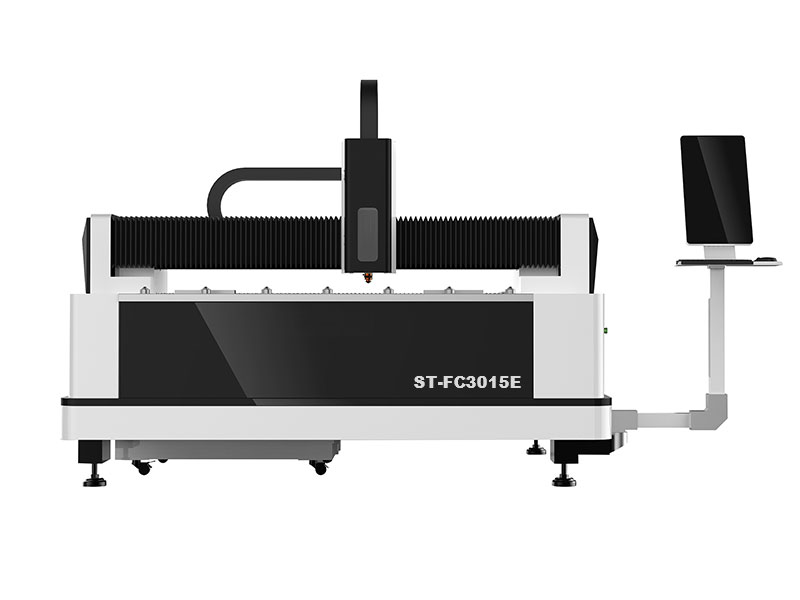

2000W Fiber Laser Sheet Metal Cutting Machine - ST-FC3015E

2000W Fiber Laser Tube Cutting Machine - ST-FC60M

Laser wood cutting machine is used for cutting and engraving wood arts, wood crafts, wood gifts, wood boxes, wood signs, wood logos, and wood letters.

You will find a series of double color plate samples by CO2 laser cutting machine from STYLECNC, which will be a good reference to buy a CO2 laser cutter.

You will find some laser acrylic cutting projects & ideas by CO2 laser cutters from STYLECNC, which will be a good reference to buy a laser acrylic cutter.