3D Plastic Laser Cutting Machine Applications and Samples

You will find a series of 3D plastic laser cutting machine applications and samples by CO2 laser cutter, which will be a reference to buy laser plastic cutter.

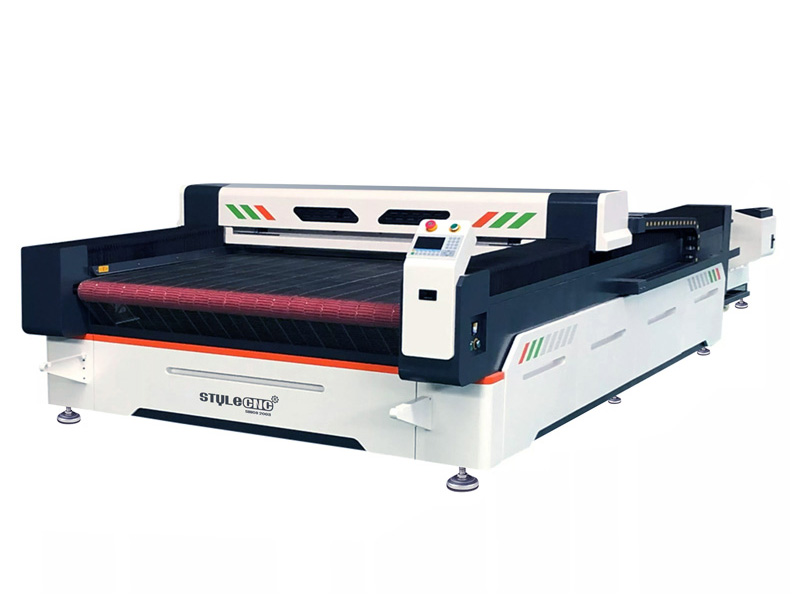

Need laser fabric cutter to cut patterns out of fabrics to make apparel, garments, clothes, fashion, dresses and suits? Here are some CO2 laser cut fabric projects for reference.

Can a laser cut fabric? The answer is yes! Simply put, laser cutting is a laser beam emitted by a carbon dioxide laser tube that is focused into a high-energy-density laser beam to quickly and stably cut materials.

The carbon dioxide laser is a gas molecule laser, and the working substance is CO2 gas. The principle is to use the transition between vibration and rotational energy levels of CO2 molecules to generate laser light.

Laser cutting technology uses high-energy-density laser beams to replace traditional tools. It features with high precision, fast cutting speed, and smooth cutting edges. Of course as long as you choose the right CO2 laser combined with the appropriate laser power.

Laser cutting can be used on different fabric types including denim, non-woven fabrics, lace, artificial leather, cotton, polyester, linen and felt to name a few.

Laser technology is flexible in processing and has high precision. It melts the material through the thermal effect of the laser beam and locks edges at high temperatures without spinning.

The recommended laser power for most fabrics is 100W. However, if you are cutting thick plush, composite fabrics or leather, the laser tube can use 130W or 150W.

The shape of the pattern designed on the fabric, the thickness of the material and the laser power used will affect the speed of laser cutting the fabric.

Adjust the height of the laser head according to different cutting methods, thicknesses and materials.

The configuration of laser head machine includes single head, double head and four head.

Your choice of single or multiple ends will depend on the pattern, size and layout design of your fabric.

Single head or double head with double guide rails are more suitable for garment layout. However, if you want faster cutting productivity, you can try two heads or four heads with one beam.

You can choose a laser cutting machine equipped with a small CCD camera, which has fast recognition speed and high cutting accuracy. It is mainly suitable for large-scale continuous cutting of small embroidery appliques, labels, trademark woven labels, electric embroidery sheets, and more.

Vision cutting systems come with high recognition accuracy and larger cutting formats for industrial laser fabric cutting table. They are suitable for continuous cutting of large-format roll fabrics such as digital printing, lace fabrics, and embroidery.

Laser Fabric Cutting Machine with CCD Camera

This is convenient for leather, striped clothing, or fly knitted shoe uppers. The projector can help project the design files onto the laser cutting machine, helping the operator position themselves for cutting and drilling.

CO2 glass tube laser cutting machines are very cost-effective compared to their level of functionality.

A laser cutting machine with a camera can replace up to 4-5 workers and can bring a good return on investment even with expenses such as rent, electricity and consumables.

The repeatable positioning accuracy of laser cutting reaches within +/-1 mm. Compared with other cutting methods, the cutting accuracy is higher than traditional manual or knife cutting.

Laser cutting is much faster compared to manual cutting methods. It is fast and can cut a variety of complex materials.

Using the same settings, you can cut multiple shapes with the same thickness level. The flexibility of this laser cutting makes cutting fabrics much easier.

When using laser processing, only CAD design files are needed to process by laser. It is not limited to complex graphics and is very suitable for customized orders.

CO2 laser cutter can be automated and the cutting speed can be set so that one person can watch multiple machines at the same time, thereby saving labor costs for the company.

Using non-contact processing, there is no tool loss; no extrusion damage to the material surface, and the material properties are maintained.

The beauty of laser cutting is that it’s so versatile and suitable for different types of materials. In addition to cutting fabrics, it is also suitable for non-metallic materials such as wood products, paper, leather, cloth, organic glass, epoxy resin, acrylic, wool, plastic, rubber, ceramic tiles, crystal, jade, bamboo products, etc. Widely used in clothing, leather, cloth toys, computer embroidery and cutting, electronic appliances, models, handicrafts, advertising and decoration, packaging and printing, paper products and other industries.

Although there are many benefits to laser cutting fabric, it also has its drawbacks. Here are some of them:

Although most fabric materials can be cut perfectly by CO2 laser, there are still some materials that may form yellow edges, such as light-colored PU leather, genuine leather and wool.

Laser processing uses thermal processing, and some materials with low melting points may have edge melting. In this case, the impact can be appropriately mitigated by adjusting machine parameters.

You will find a series of 3D plastic laser cutting machine applications and samples by CO2 laser cutter, which will be a reference to buy laser plastic cutter.

Looking for a CO2 laser cutter for 3D pencil cups and pen holders of plywood with living hinges? Free download the files for 3D pen holders and pencil cups.

Need a laser cutter to cut custom foam inserts for packaging & shipping? Review the best laser cut custom foam packaging projects and ideas with CO2 laser tube.