3D Laser Cutting Wood Plans with CO2 Laser Tube

Looking for a laser cutting machine for wood? Review the 3D laser wood cutting plans, which will be a reference to buy laser wood cutter with CO2 laser tube.

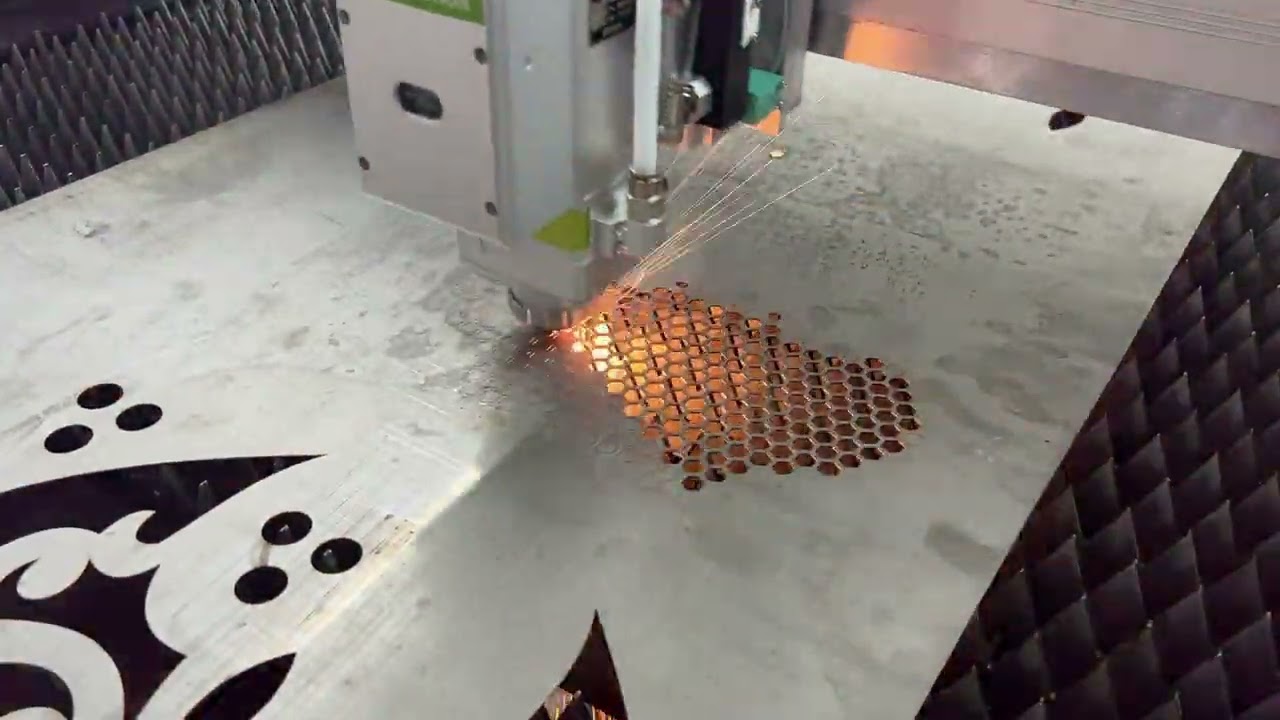

1500W fiber laser cutting machine is a professional automatic precision metal cutting tool to cut various metal signs made of stainless steel, mild steel, carbon steel, galvanized steel, aluminum, copper and brass.

Fiber laser technology has completely revolutionized the system of sign creation on metals by embodying precision, speed, and versatility. A 1500W fiber laser cutting machine is one good example that efficiently cuts a number of metals, such as stainless steel, aluminum, and brass, with flawless accuracy. This article explores the capabilities and benefits of this advanced machine, making it a go-to choice for businesses seeking high-quality and durable signage.

This guide will cover everything you may want to know about the 1500W fiber laser cutting machine, from its features to how to choose the right machine. Be it retail, manufacturing, or design, this technology offers unmatched performance when creating intricate, professional-grade metal signs.

Precision and durability are game changers when it comes to modern signage, which introduces advanced technology in fiber laser cutting for intricately designed metal signs. Thus, with very high-intensity laser beams, the metals are cut accurately, leaving smooth edges and very detailed designs. Its application in signage ensures that even intricate logos and patterns can be replicated with perfection.

This is not only for aesthetics but also in terms of efficiency in the process. It actually works faster than previous methods of cutting. As such, businesses stand to create more signs in less time without compromising on quality, thus remaining fitting for places with high demand. Moreover, because the laser is non-contact, the possibility of material deformation is minimal, hence retaining the integrity of even very thin metals.

The versatility of the fiber laser cutter extends beyond simple shapes; it handles intricate engravings and designs on various metals like stainless steel, aluminum, and brass. It will make this a go-to solution for industries seeking to make eye-catching and long-lasting signage.

1500W fiber laser cutting machine is typically used for cutting carbon steel, silicon steel, stainless steel, aluminum, titanium, galvanized steel sheet, pickling board, aluminum zinc plate, copper, brass, and other metal materials.

Applied Industries

Sheet metal fabrication, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing, and various metalworking industries.

Stainless steel signs are also very popular because of their excellent corrosion performance and their bright, polished appearance. Durable enough for outside or inside use, it will continue to look professional for a long time. It is also one of the metals that can be laser-cut into very intricate designs, making it a great option for custom signage.

Aluminum is lightweight and has good corrosion resistance, best serving large or weather-exposed signs. It is easily cut and shaped to allow creative designs without the loss of structural integrity. Besides, tending to be less costly compared with other metals makes it very affordable for businesses and individuals.

Brass and copper are premium materials due to their usual usage in decorative or high-end signage. This is because they give off a noble appearance and feel. They offer a rich, polished finish that adds grace to a place. Although slightly higher priced, the aesthetic appeal and the ability to develop a unique patina over time make them worth investing in.

Mild steel is another popular material option for metal signs, especially regarding industrial or rustic themes. This material really stands out regarding durability and has the possibility of other aesthetic finishes, such as paint or powder coating, for appearance enhancement and rust protection. It can be cheap and versatile, which allows its application on a wide range of signage projects-from functional to decorative.

• High Precision and Accuracy: 1500W fiber lasers are very precise to yield complicated cuts and engravings with no failures. Therefore, professional artwork on metal signs is possible.

• Speed and Efficiency: Their cutting speed reduces production time, making them cost-effective for bulk orders or time-sensitive projects.

• Low Maintenance: Fiber lasers are very durable and require low maintenance. Long-term operations with reliability and low operating costs are therefore guaranteed.

• Variability in the Cut Material: From stainless steel to aluminum and brass, these cutters work on different metals for various signage and design requirements.

• Eco-Friendly and Energy-Efficient: The 1500W fiber laser consumes less power compared to previous methods, making it friendly to the environment and cutting down operating costs, hence finding its place as sustainable for businesses.

The 1500W fiber laser machine is designed for versatility and power, precision, and efficiency in the cutting of metals. This feature-rich device offers reliability, productivity, and quality assurance, making it indispensable for many industries.

The laser source is the heart of a fiber laser machine, and stability with high efficiency at the source ensures precision cutting with less energy consumption. It delivers continuous output for intricate pattern cutting and thick materials at low operational costs.

Equipped with user-friendly control software, this machine will let users easily operate and create designs highly complex in nature. It allows for streamlined workflows, and minimum errors, and supports various file formats that will adapt to the needs of projects or customers.

The robust machine build promises stability during high-speed operations, while an efficient cooling system keeps overheating at bay. This ensures consistent performance even on extended use and thus gives a longer life to the machine.

Featuring a powerful 1500W laser, this machine excels in high-speed cutting and enables quicker completion of projects without any compromise in quality. It is ideal for industries where orders are to be returned very fast.

Fiber laser machines require minimal maintenance due to their solid-state design. This minimizes down-time and other operating costs, hence an economical choice when long-term reliability is looked at as a factor of investment by an enterprise.

Choosing the right 1500W fiber laser cutting machine is all about perspective in ensuring your operations are at their best and churning out quality results on a consistent basis. This should include paying attention to material compatibility, features, and support in securing a well-informed decision that shall fit your needs.

First, let the machine be able to work with metals and their thickness. A 1500W fiber laser would perfectly cut, say, stainless steel, aluminum, and brass, up to a moderate thickness. Ensuring this compatibility will maximize efficiency and avoid unnecessary limitations.

A machine is only as good as the after-sales support accompanying it. Choose a manufacturer or supplier that offers reliable after-sales service, including technical support, the availability of spare parts, and a warranty. Strong customer support ensures minimum downtown and peace of mind for a long time.

Most of the modern fiber laser machines now come with value additions such as an automatic loading system, high-level safety mechanisms, and real-time monitoring. In addition to increasing productivity, these features make the machine much safer to work on and more user-friendly for any new user.

Energy efficiency is also one of the key parameters of the selection of a laser cutting machine, as it directly influences the operational cost. Seek a machine that uses advanced technology to optimize energy consumption without influencing performance. This will save money and reduce the environmental footprint of your operations.

A well-designed, sturdy machine will ensure stability and accuracy in high-speed, hard-cutting operations. Ensure the frame is good and the components are of quality to avoid issues like vibration or wear and tear after some time. Such a strong machine provides complete accuracy and durability for several years of intense use.

Looking for a laser cutting machine for wood? Review the 3D laser wood cutting plans, which will be a reference to buy laser wood cutter with CO2 laser tube.

2000W fiber laser cutter is an automatic low-power laser metal cutting machine for custom metal signs, logos, parts, letters, jewelry, 3D models and puzzles.

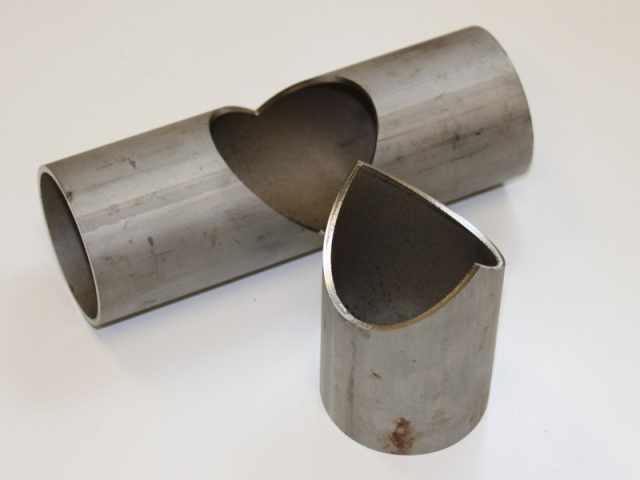

Round metal pipe and tube fiber laser cutting machine is suitable for carbon steel, silicon steel, stainless steel, aluminum, iron, alloy, and more metals.