With 8 hours per day, normally the CNC router can work for over 8 years without any problems with carefully maintenance. But if with heavy workload, the spindle may need to be changed every 5 years.

If you bought a CNC router from STYLECNC, the frame could work for over 10 years without any problems. We have three axis dust-proof can protect the slider and guide rail away from the dust made from the machine. If other companies, you may take attention to the slid after 1-2 years using.

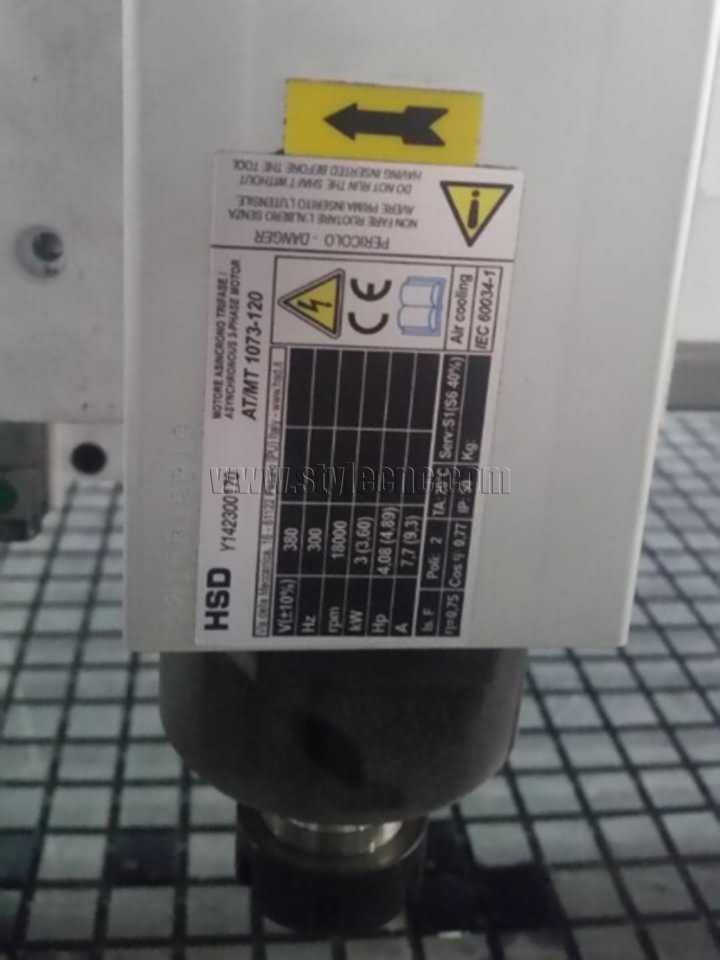

Of course the different specs will influence the service time of a CNC router. A CNC router with Yaskawa servo motors and drivers, HSD spindle definitely can work longer than normal specs CNC router.

Then how to maintain a CNC router?

1. Better not make the machine working over 10 hours per day. Keep there’s always clean water in the water tank and water pump for the parts cooling. Also, we should keep changing the cooling water to keep the similar temperature which can make the good cooling effect. When winter, if the working place is very cold. We should change the water to antifreeze otherwise the spindle may damage when long time using.

2. After daily using, we should perform cleaning. It is necessary to clean up some of the dust on the machine and to regularly lubricate the drive system.

3. The machine should not be placed at a humid place. We should choose a well-ventilated place for the machine.

4. Do not keep the one side of the CNC router working for a long time. It will cause the screw and guide rail cannot be properly lubricated because of not enough connect with the gantry.

5. Before operating, we should check each connect part of the control box and the wire. With long time using, the abrasion of the wire skin may result in leakage.

6. Clean up the gaps of the machine weekly.

7. Do not place debris, corrosive materials, or magnetic substances that can interfere with the machine's work on the working table.

8. For a longer time service time, we’d better choose original control system.

You can also contact STYLECNC engineers for more information of daily maintenance of CNC router.