In this article, the word “end” will be used to refer to all CNC machine cutting surfaces. In the industry, different types of ends may be referred to as ends, bits, mills, cutters, or drills (to name a few).

It is important to remember from basic CNC routing that all CNC machine ends, from plunge drills to stylized edging bits, depend on the ability to pass the material they have removed out of the space they are operating in. In this way they can be considered to be simultaneously a cutting surface and a particulate pump. Anything that prevents the removal of the particles also prevents the end from continuing to operate. The primary cooling mechanism for the end is the removal of material, therefore material that stays in contact with the end for longer also decreases its cutting ability by softening the end with heat and thus increasing its wear rate. The recommended speeds and removal rates provided by the manufacturers of the CNC machine ends for specific materials should always be used.

Equipment and Supplies Needed for Operating CNC Machine

- Face shield / Face protection.

- Safety glasses / Eye protection.

- Long hair securely tied back / Hair protection.

- Face mask or Respirator / Breathing protection.

- Long sleeves and pant legs / Skin protection.

- Earplugs or Earmuffs / Hearing protection.

- Brush for removing sharp chips from surface / Hand protection.

- Never wear gloves or move hands near a running CNC machine.

- Closed-toe shoes with good traction / Foot and balance protection.

Safety Concerns to Watch with CNC Machine

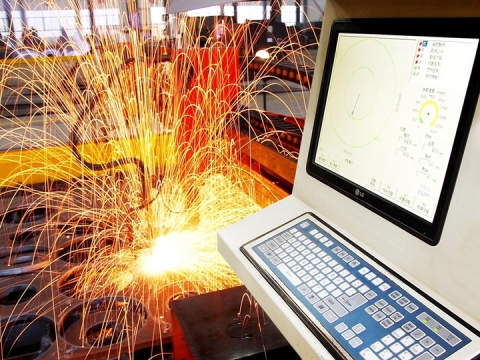

There is a significant risk of fire caused by excessive friction with improper clearing of chips or dull cutting surfaces on a CNC machine end.

Cutting conductive materials like metals and carbon fiber creates both dust and coarse particles that are capable of settling inside of electronic equipment and causing electrical shorts, electrical fires, and battery explosions. Always use proper ventilation, clean up particles, and have a working fire extinguisher at hand.

Inhaling dust from some materials can cause respiratory diseases, poisoning, and cancer. Consult and post the MSDS (Material Safety Data Sheet) for the materials you are cutting by consulting your OSHA representative or conducting a search for the MSDS online.

Risk of explosion occurs when high-surface-area particles (dust) produced by a CNC machine floating in the air are exposed to ignition sources like electrical motors or hot cutting ends. Ensure that all dust is vacuumed away while cutting and that the area is well-ventilated.