Precision CNC Plasma Cutter Table for Metal Cut & Drill

You will see how does a high precision CNC plasma cutter table cut and drill holes on sheet metal with plasma torch, drilling head, flame torch in this video.

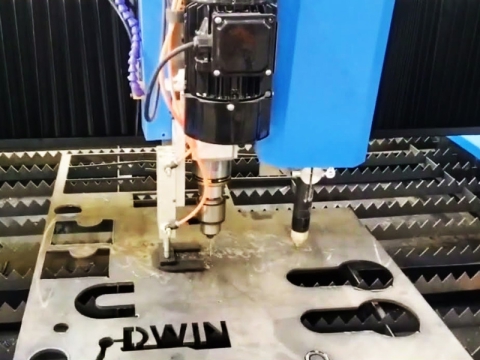

You will see CNC plasma cutting table with drilling head for sheet metal cutting and hole drilling with high speed and high precision in this video.

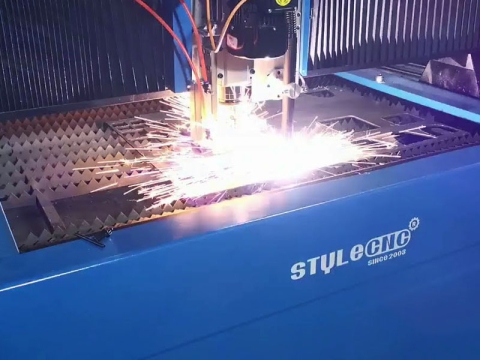

Plasma cutting has the characteristics of high speed and high efficiency, high kerf finish, and large applicable cutting range. CNC plasma cutting table has been widely used in machinery, shipbuilding, steel structure, automobiles, pressure vessels and other industries. It is gradually replacing flame cutting in certain industries. Dominance in these areas.

In addition, compared with the mechanical cutting method, the plasma cutting speed is much faster and it is easier to perform non-linear cutting. In cutting aluminum, copper, stainless steel and other metal materials, it is the strength of CNC plasma cutting machine.

CNC plasma cutting table with drilling head combined is mainly used to cut and drill metals, such as for steel, copper, iron, galvanized plate, titanium plate, and more sheet metal cutting.

You will see how does a high precision CNC plasma cutter table cut and drill holes on sheet metal with plasma torch, drilling head, flame torch in this video.

High speed CNC plasma table is suitable to cut all types of sheet metals such as carbon steel, mild steel, iron, brass, copper, aluminum and stainless steel.

CNC plasma cutter with rotary device besides the plasma cutting table can cut sheet metals, square and round metal tubes to realize multi-functional cutting.