Custom EVA Foam Cuts With CO2 Laser Cutter Machine

Are you searching for a precision laser cutting system for custom EVA foam projects? Review the awesome cuts by STYLECNC CO2 laser foam cutter for reference.

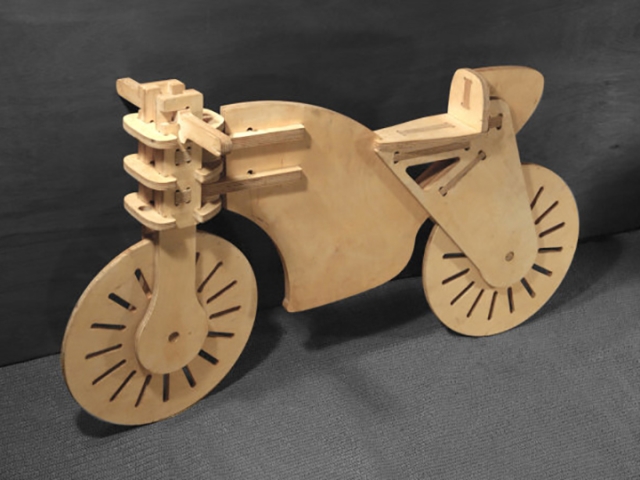

Looking for 3D wood puzzle laser cut files, laser cut projects or laser cut ideas? Review the free 3D laser cut wood puzzle vector files of DWG, DXF, and CDR for plywood houses, wood tractors, wood bulldozers, and decorative gift boxes of hinged, lid, and rounded.

Laser cutter is a machine tool that adopts a fiber or CO2 laser beam to cut wood, plywood, MDF, acrylic, plastic, leather, fabric, textile, and metals, which is used for industrial manufacturing applications, school education, small business, home shop, and hobbyists. A laser cutter works by directing the tool path of a laser beam, by CNC at the material to be cut. The material will melt, burn, and vaporize, which will be blown away by gas, leaving a smooth edge with a high-quality cutting surface. Laser cutters can be used in various industries.

DIY craft and digital fabrication have become a fascinating hobby with the blessing of 3D laser cut technology. Whether you are a hobbyist or a seasonal woodworker, 3D wood laser cutting is going to through challenge and also will showcase the beauty of woodworking. Precision engineering and creativity together create unimaginable beauty.

Complex and intricate designs for puzzles are now more précised and perfectly fit. The advancement of a 3D laser cut machine for wood shows the ability to turn a plain wood piece into a functional 3-dimensional object!

The high-power laser beam does the engraving and precise cut and delivers aesthetic products out of wood.

3D laser-cut wood puzzles are perfectly fit products. This method offers precise and faster manufacturing. Let’s take a look at the benefits of 3D laser-cut wood puzzles.

✔ Precision and Detail: Laser cutters can achieve extremely fine details that are difficult to replicate with traditional woodworking tools.

✔ Customization: You can design your puzzles or modify existing designs to suit your preferences.

✔ Consistency: For commercial and large manufacturing projects a 3D laser cut machine can consistently reproduce a product with identical accuracy.

✔ Educational Value: These puzzles are great for developing spatial awareness, problem-solving skills, and patience.

✔ Minimal Waste: Precision cutting ensures minimal waste and increases efficiency.

✔ Decorative and Functional: Finished puzzles can serve as beautiful decorative pieces or functional items like boxes or models.

With access to design files, next choose a project. Here are some project ideas that will help and inspire your next 3D laser-cut wood project.

I. Jigsaw Puzzles

Create custom jigsaw puzzles by engraving a photograph or artwork onto the wood before cutting. Laser-cut jigsaw puzzles are more durable and aesthetically pleasing. Ensure the image aligns perfectly across all pieces after cutting.

II. Interlocking Puzzles

Interlocking puzzles are the classics with simple geometric shapes. They can come in complex designs as well. These puzzles consist of pieces that fit together in a specific way to form a cohesive structure.

III. Mechanical Puzzles

These are complex and intriguing puzzles that can include gears, levers, and other mechanisms. Mechanical puzzles come with moving parts that may need to be manipulated to solve the puzzle.

IV. 3D Animal Puzzles

3D animal puzzles are fun. These puzzles involve assembling flat pieces to form a three-dimensional animal model.

V. Architectural Models

These serve as educational tools and also decorative objects. As puzzles, architectural models offer a unique way to recreate famous buildings or structures.

VI. Puzzle Boxes

Puzzle boxes are usually gift boxes. These boxes come with functional puzzles and to open the box one must solve the puzzle first.

Combining creativity and precision, a 3D laser-cut wood can offer several unique and successful projects. A few tips may come inspiring to create something new.

• Designing the puzzle is the first step to start your project. Use vector graphic software to create your designs. Ensure that your puzzle pieces will fit perfectly. Always take a test cut to check your settings and the fit.

• Three types of wood materials are most commonly used, they are, plywood, hardwood, and acrylic. Choose high-quality plywood to avoid issues with voids. Use maple, walnut, or cherry wood for premium production and finish.

• Once the product is done sand the edges to remove any burn marks. Apply a finish to enhance the look at protect the wood.

You can add paint and colors to your products to make them eye-catching. Another personal touch like engraving is very common. This will make the products unique and make it a signature item.

Free Download 3D Laser Cut Wood Puzzle Files

Are you searching for a precision laser cutting system for custom EVA foam projects? Review the awesome cuts by STYLECNC CO2 laser foam cutter for reference.

Review the laser cutter engraving machine for wood projects as a good reference to buy the best laser wood engraver cutting machine.

You will find a series of 2D/3D plywood laser cutting applications & samples by CO2 laser cutters, which will be a reference to buy laser plywood cutter.