3D Laser Cutting Wood Plans with CO2 Laser Tube

Looking for a laser cutting machine for wood? Review the 3D laser wood cutting plans, which will be a reference to buy laser wood cutter with CO2 laser tube.

You will find a series of laser metal cutting machine projects & ideas from STYLECNC, which will make you have an idea to find all-round 2D/3D metal cutting solutions for sheet metals and metal tubes.

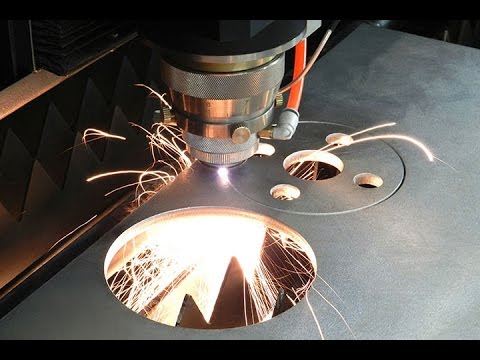

Lasers are magical, and lasers have been used in various industries, such as metal cutting. The laser beam is focused into a small spot with a minimum diameter (can be less than 0.1mm), so that the focus can reach a high power density (can be more than 106W/cm2). At this time, the heat input by the beam (converted by light energy) far exceeds the part reflected, conducted or diffused by the material, and the material is quickly heated to the vaporization temperature and evaporated to form a hole. With the relative linear movement of the beam and the material, the hole is continuously formed into a slit with a narrow width (such as about 0.1mm). The thermal effect of trimming is very small, and there is basically no workpiece deformation.

In the process of laser metal cutting, auxiliary gas suitable for the material to be cut is also added. When cutting steel, oxygen is used as an auxiliary gas to produce an exothermic chemical reaction with the molten metal to oxidize the material, while helping to blow away the slag in the kerf. For metal parts that require high machining accuracy, nitrogen can be used as an auxiliary gas in the industry.

Most organic and inorganic materials can be cut with a laser. In the metal processing industry, where industrial manufacturing plays a very important role, many metal materials can be cut without deformation, no matter what kind of hardness they have.

Looking for a laser cutting machine for wood? Review the 3D laser wood cutting plans, which will be a reference to buy laser wood cutter with CO2 laser tube.

Fiber laser cutting machines cut square metal pipe and tube projects with stainless steel, carbon steel, silicon steel, alloy, aluminum, and iron.

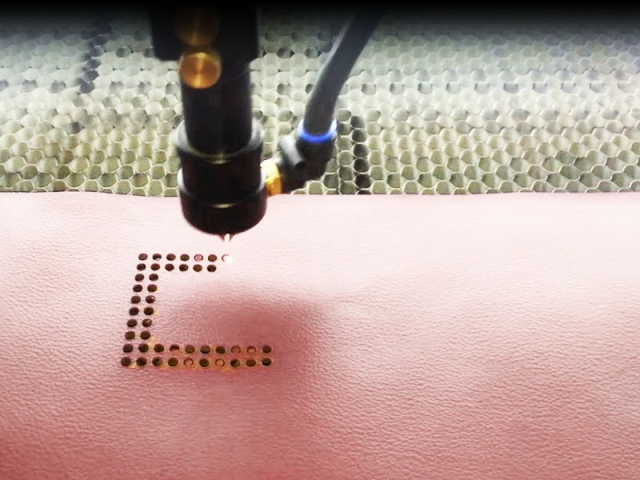

The best precision laser leather cutting projects & plans by CO2 laser cutting machines from STYLECNC, which will be a reference to buy laser leather cutter.